Man you can't complain with those results, the only thing I would check when the weather warms up is that the load is still OK, it should be but I wouldn't want to leave some rounds in a hot place and then shoot them.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 90

-

26-10-2021, 06:18 PM #31Member

- Join Date

- Jul 2014

- Location

- BOP

- Posts

- 4,074

-

-

26-10-2021, 06:31 PM #32

For sure, was pretty warm day when I did the initial work up full sun at 22plus degrees.

Today was like 12 degrees and results were pretty much the same.

But yes I am conscious that SF is known to be temp sensitive. This is why I wasn't fussed on chasing a faster accuracy node, as it may well be ok on a cool day but not so flash on a hot day

Stoked with that accuracy.#DANNYCENT

-

28-10-2021, 05:12 PM #33

Well finally after a week and a half my brass turned up.

I decided to weigh the Starline to see I it was similar to the Sako brass I have been using for my work up....I wish I hadn't.

The Sako brass on average weighed 186gn per case and the Starline 195gn per case average.

So it looks like the Starline brass is thicker which isn't necessarily a problem as I'm not struggling for case capacity but it will be interesting to see if I get an increase in velocity and or pressure.

I have full length sized the lot and chamfered the necks, I will prime it all later tonight then get some loaded first thing in the morning with the intention to get to the range tomorrow.

I will stick with my initial plan and load 3x 58.7gn, 3x 59gn and 3x 59.3gn and see what happens

#DANNYCENT

#DANNYCENT

-

28-10-2021, 09:05 PM #34

50 cases ready to load in the morning, as an unexpected bonus there was 101 cases in my bag of 100

#DANNYCENT

#DANNYCENT

-

29-10-2021, 01:12 PM #35

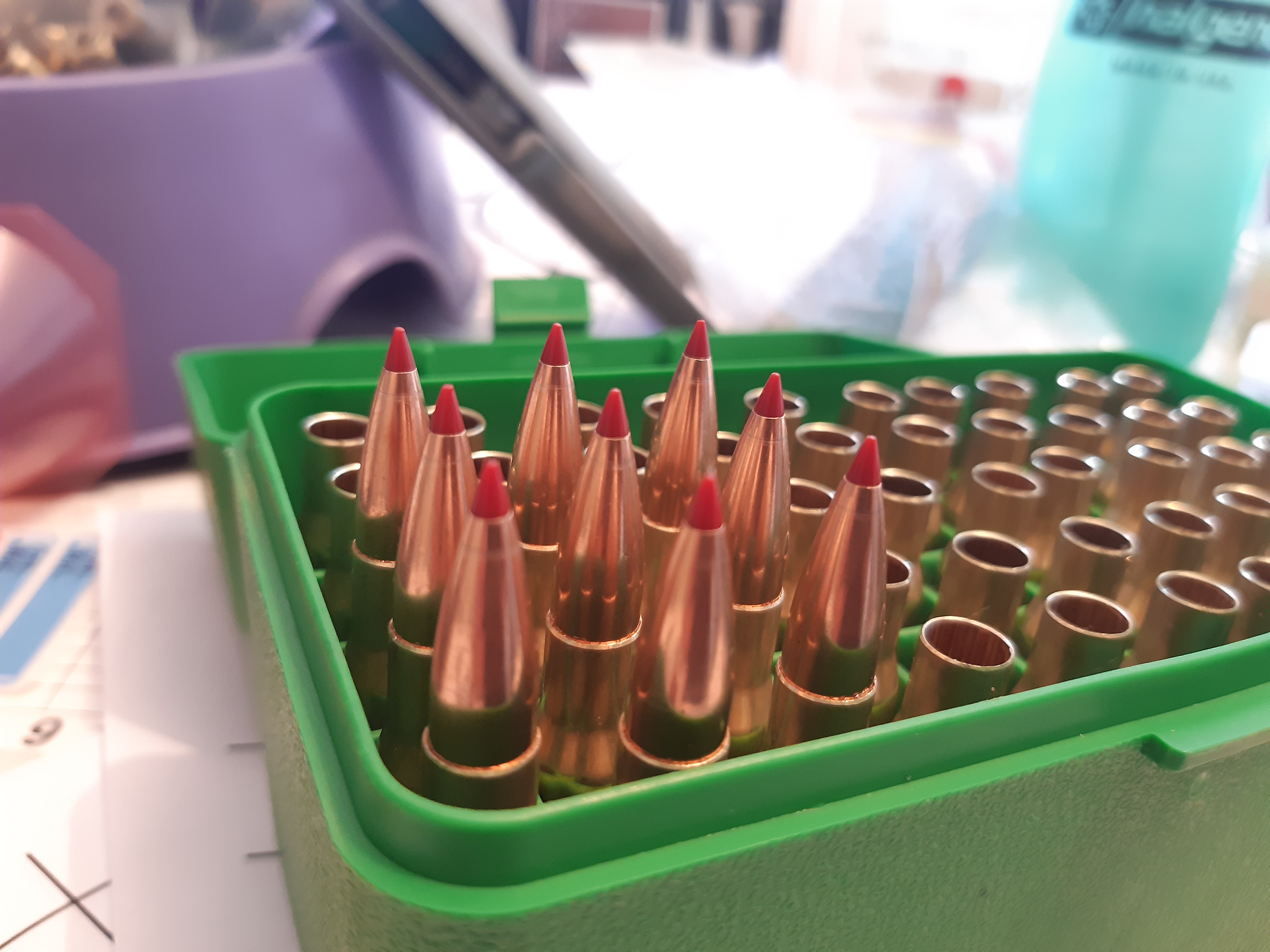

New brass test loads all sorted unfortunately sick child at home means no range time till the wife gets home

#DANNYCENT

#DANNYCENT

-

29-10-2021, 07:30 PM #36

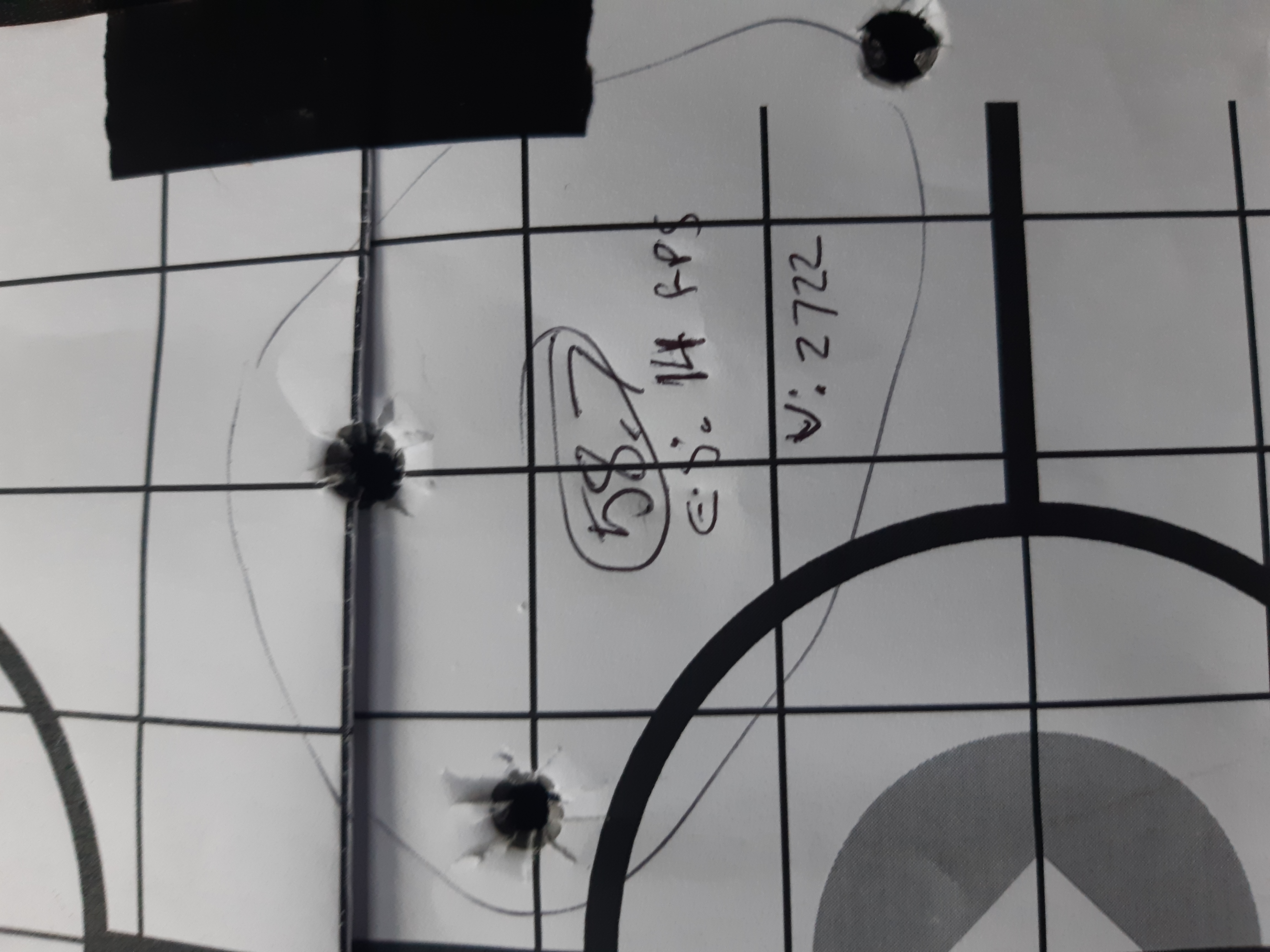

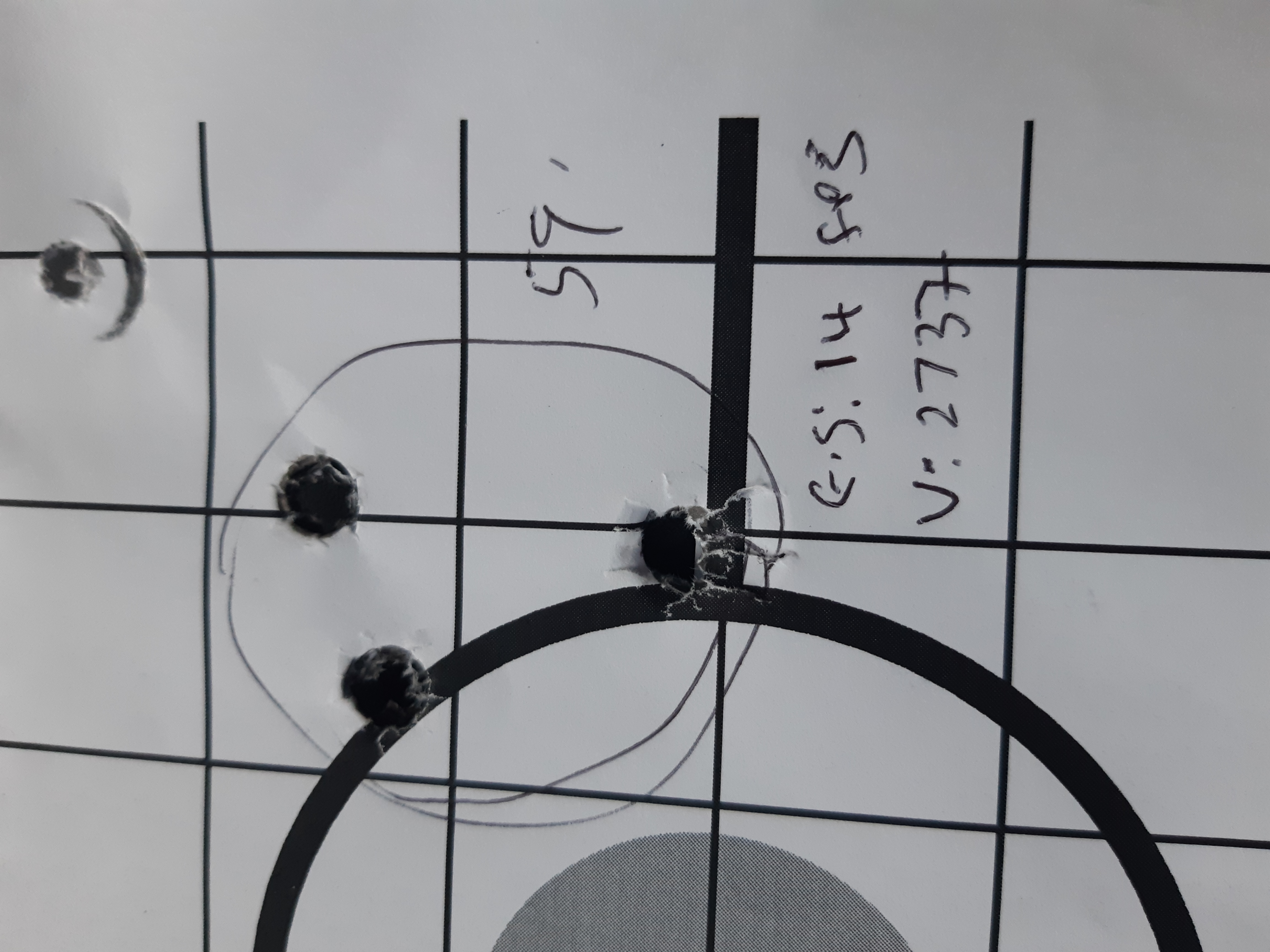

Well the range time resulted in more questions than answers.....

New brass definitely gives more velocity for less powder but even though my E.S was pretty good over all 3 loads the accuracy was average at best....

May have to do a full ladder again

Even my lowest charge of 58.7gn was higher velocity than my 59gn load with the sako brass.

Will scratch my head and load up a new ladder tomorrow.

Any how pics have E.S and average velocity written on them.

#DANNYCENT

#DANNYCENT

-

29-10-2021, 08:31 PM #37

so the new brass is smaller capacity....thus the heavier....like milserp stuff.

as for the poorer accuracy....buggered if I know what you did.

BUT you broke golden rule mate....where is you test group with other brass/load to confirm it wasnt somfin else at play???? LOL

your 59 is still just over inch.....be interesting to see that again with same brass...now twice loaded....fresh brass and the other brass.....see if any difference,you know remove the doubt.....

you didnt change HOW you were set up rest wise???

-

29-10-2021, 08:40 PM #38

Nope no other changes, the sako load shot the same 59gn load well twice with fired then resized brass both times.

Might take you up on that MD and load 59gn again in fired resized brass, new brass and the sako brass, the E.S was still very good with a 14fps so every chance I may be able to tune the load by fiddling seating depth.#DANNYCENT

-

29-10-2021, 08:57 PM #39

Have you weighed your new brass & how does the weight compare to old brass you were using? I think MD is probably on the money, the new brass is heavier thus thicker walls, less internal capacity reaching pressure earlier and more fps for same powder load. In my 6506ai and different brass (Norma vs RP) there was about 10gn difference in weight of brass and that needed about 1gn difference in powder to compensate (ie find accuracy node).

-

29-10-2021, 09:29 PM #40

Yup it's on the previous page of this thread, and similarly there is 9gn difference in weight between the sako brass and the Starline brass with the Starline being heavier and thus likely thicker walls etc.

It has crossed my mind that maybe I should try dropping my charge weight till I get the same velocity as the sako brass from results already seen above it would seem dropping my charge weight by between 1gn and .7 of a gn should see me in the ball park. I might try this before doing another full ladder#DANNYCENT

-

29-10-2021, 09:55 PM #41Banned

- Join Date

- Mar 2015

- Location

- North Canterbury

- Posts

- 5,462

A learned forum member was explaining to me earlier this week that neck tension variations will do this

-

29-10-2021, 10:03 PM #42

The new brass is annealed from factory and then I full length size it all so it is as consistent as it can be. I didn't notice any inconsistencies with the amount of force required to seat projectiles and it is something I pay particular attention too.

I don't think this is the issue, I am leaning towards the heavier brass theory. Will load up some more tomorrow an see how I get on#DANNYCENT

-

29-10-2021, 10:16 PM #43

Have you tried necking the case down to .277 then sticking a new barrel on to suit?

Flappy Disc Customs Bespoke Hunting Rifles

-

30-10-2021, 07:17 AM #44Member

- Join Date

- May 2020

- Location

- Gore

- Posts

- 169

-

30-10-2021, 09:29 AM #45

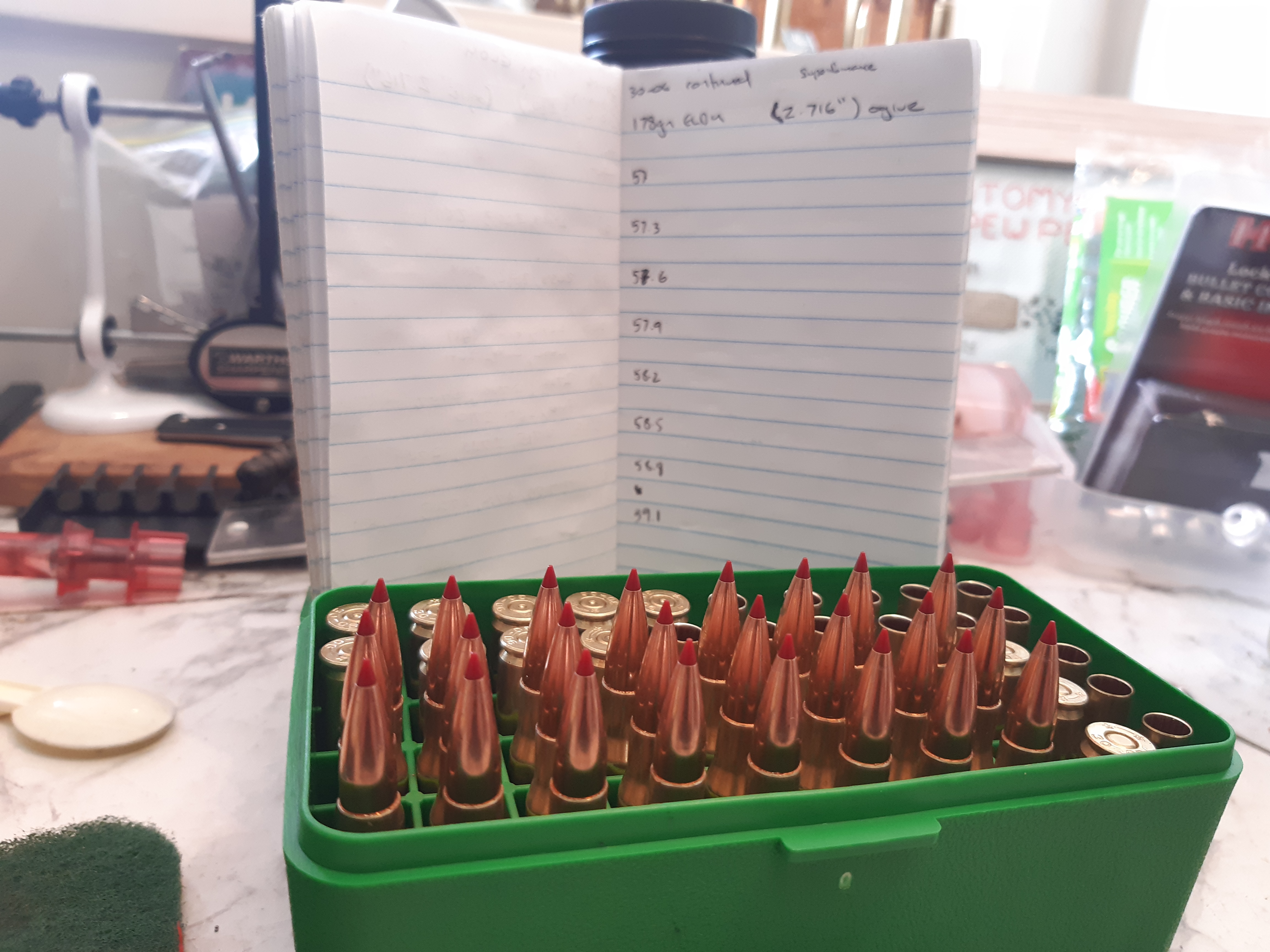

Well range time is precious and nothing gives good consistent data like a comprehensive ladder test....Hopefully

I have loaded another ladder test with the Starline brass from 57gn to 59.1gn in .3gn increments Hopefully this will give me some better data and results

#DANNYCENT

#DANNYCENT

Similar Threads

-

"Desperately seeking", no not Susan, a 12 bore load with fibre,not plastic wads.

By Kiwi Sapper in forum ShotgunningReplies: 47Last Post: 27-11-2022, 11:38 AM -

Shooting Apps "Range Buddy" and "Reloading Assistant"

By Dead is better in forum Resource LibraryReplies: 4Last Post: 14-01-2017, 05:23 PM -

Evolve LED Light Bar For Offroading in sizes 18",20",28",36",43"

By pighuntingnz in forum Outdoor TransportReplies: 4Last Post: 27-12-2016, 08:05 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

115Likes

115Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks