Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 37 of 37

Thread: my 7x60 wildcat project

-

23-07-2023, 04:24 PM #31Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,751

Resident 6.5 Grendel aficionado.

-

-

23-07-2023, 07:14 PM #32

nah one was .222 with heavier projectile and the other was a whackamole loaded in .270 neither had been checked after loading...just being lazy..my fault entirely and lesson learned.

75/15/10 black powder matters

-

24-07-2023, 09:32 PM #33Member

- Join Date

- Jan 2023

- Location

- Nelson

- Posts

- 61

I reformed some 270 Win Norma cases into 257 Robts cases years ago in one pass using RCBS 257 Robts full length sizing dies. My lube of choice was Kiwi nugget neutral shoe polish & they all formed in one pass in my Lyman Orange Crusher press. They were unfired cases & I didn't anneal till I'd finished with inside neck turning etc. From memory, a few has slight dimpling at the neck/shoulder transition but that blew out with no problems upon firing. As an operation, it is very similar to what the OP has done to form his 7x60 cases. Sorry if I didn't pick up on it earlier in the thread but I would recommend neck reaming/turning to remove the thickening that will have occurred below the neck/shoulder transition so the neck is a consistent thickness right through. If your chamber is slightly on the loose side, not a reflection of Jaco's work but the way the reamer was cut, you might get away without neck reaming but I wouldn't be keen to ignore it.

-

25-07-2023, 11:08 AM #34

so if Ive got this right...and Ive re-read it 3 times to try and do so.... you have created a stretched 7x57 and have in effect done nothing more than made the case body 3mm longer but maintained the same diameter at shoulder so a SLIGHTLY less taper to the body????

if you used fireform load and a 7x57mm case you would end up with right case but neck that was very short????

my thought on using a 270-280 case is the tip wont have to be worked much at all....but your 25/06 case shows it will work,the fatter neck to begin with may eliminate that wonky look,but agree with Brian it will dissapear on first fireing...I made some 25/06 out of 270 and had similar thing.75/15/10 black powder matters

-

25-07-2023, 12:46 PM #35Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,186

Greetings @-BW-,

I am not surprised that you are getting better results with 30-06 brass. Resizing will only be reforming a little of the shoulder into neck so you are mostly neck sizing and setting the shoulder back a couple of mm. I suspect that you length to the neck in your 7x60 is around 51 to 51.5mm with the .30-06 53.62mm. The 7x64 is over 55 mm. There is a wildcat 6.5mm case rolling around on my bench that was made from a 30-06 case that has a length to shoulder of around 50mm and has formed nicely.

Regards Grandpamac.

-

09-08-2023, 10:43 AM #36

Short update.

As load development progresses, I was focused on the brass and velocities. I decided to fit a scope anyway just to see what the groups looked like, and bugger me dead... the rear scope mounting holes are off-centre. The old fella who was the previous owner must've hunted all these years with a crooked scope. I must ask the family how many deer he actually shot over the years! But I digress..

The rifle is back in Jaco Goosens workshop to have new mounting holes drilled, and an old gunworks suppressor fitted that I had sitting around.

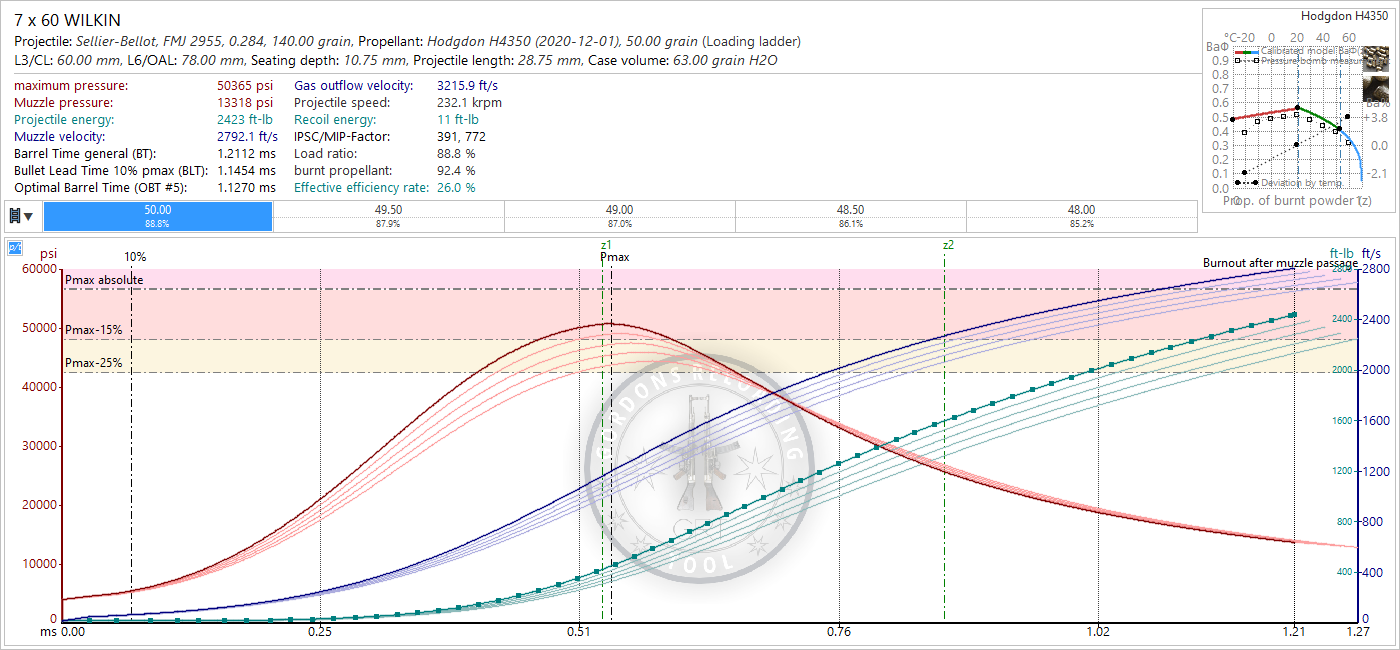

In the meantime, I have dabbled with Gordons Reloading Tool , and been very impressed.

If the modelling estimates are correct, (and actual chrony velocity results are matching the GRT estimates)) first testing indicates approx 2800fps with 140gr Projectiles, @50.3k Pressure.

-

15-09-2023, 03:50 PM #37

Things had stalled when I went to install the scope and found one of the bases was crooked, so I took my annoying little problem to @Jaco Goosen and his patience and expertise found that the front base was .136" offline, which he corrected perfectly.

While there asked him to fit the suppressor, and he added an expertly machined and beautiful thread protector.

I also requested a modification of a 7x64 Lee case gauge to the length I required, about 59.8-59.9mm or thereabouts from a pre-made case, and he did a perfect job of that one too.

Once load development is somewhat finished it will be back to Jaco's place so he can have a shoot!

Since I also recieved a half box of Lapua .30-06 cases from Tony @ tenpointone, next week will be forming & trimming some more cases, and back into load testing.

Another update soon..

Similar Threads

-

Attempting a new .224 wildcat

By Wingman in forum Reloading and BallisticsReplies: 46Last Post: 26-06-2023, 09:56 PM -

Wildcat/brassforming/fun project question

By Tuckerbox in forum Reloading and BallisticsReplies: 3Last Post: 30-08-2017, 01:05 PM -

My new wildcat round

By Maca49 in forum Reloading and BallisticsReplies: 11Last Post: 12-06-2014, 12:13 PM -

30Apache (30-223 wildcat)

By kimjon in forum Reloading and BallisticsReplies: 13Last Post: 01-02-2013, 09:59 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

38Likes

38Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks