Thanks Gmac. The one i have been playing with to no avail is a BSA E P14 sporter. Barrel a bit naff but you would still think it could be ok (bullets arent keyholing) and you cant get any bullet out far enough to touch the rifling so the throat is probably poos

As in the projectile is only in the neck 1-2mm and barely touching. That is with a 200+gr projectile timattalon lent me.

Chamber is quite large also as cases have no show of fitting the other 303 i will be experimenting with.

Presently Ive tried a couple of projectiles out of the P14 and really only a bush rifle accuracy-3-4" at best. puts a couple close together then throws the rest. Bedded it, and even tried a bunch of pressure under the fore-end. Still the same.

Have a couple of other bullets to try but suspect its a done deal

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

View Poll Results: What fraction of a grain charge weight do you test new loads?

- Voters

- 42. You may not vote on this poll

+ Reply to Thread

Results 31 to 44 of 44

-

21-01-2021, 06:31 PM #31Member

- Join Date

- Jan 2018

- Location

- kaiapoi

- Posts

- 7,369

-

-

21-01-2021, 06:48 PM #32Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,181

Greetings Again,

One thing worth trying is to re crown the barrel, possibly including shortening is a bit. .303 barrels are often worn at the muzzle from dragging a gritty pull through string across the crown. The first barrel I had in my scoped no4 was badly pitted but still shot well as the crown was OK. It was a mission to clean so I had a near new barrel that had been sitting in the cupboard fitted. Shot the same but cleaning was easy. Most riffles benefit from a re crown. I have a P14 in the cupboard that has been fitted with a target barrel and stock so that is an option as well. I have also found that flat base round nose projectile like the Hornady 174 grain RN shoot well in rough barrels.

Regards Grandpamac.

-

21-01-2021, 07:14 PM #33Member

- Join Date

- Jan 2018

- Location

- kaiapoi

- Posts

- 7,369

Back when I had access to a lathe i did just that.

And yes I have a dozen of those to try as well

-

21-01-2021, 08:50 PM #34

It has been a while since I worked up a load with a new projectile & caliber for target shooting.

I use ADI2208 for both .223 and .308

With my .223 it was 0.1 gr steps up to the point of pressure signs, then I backed of 0.2 gr.

That load groups well and shoots well.

The last (target) .308 load I worked up was from 41.5 gr to 45.0 gr in 0.3 gr steps.

I found two nodes in that range that grouped well.

Then I retested with 0.1 gr steps from 0.5 gr less to 0.5 gr more around the apparent nodes.

From memory this testing took about 100 rounds and found two accurate nodes that group well.

The nodes are separated by 2.7 grains.

One can be used for shorted ranges (up to 600 yards) and the other longer ranges.

To keep things simple I use to longer range load at both short and long ranges.

-

21-01-2021, 11:41 PM #35

The general process is unchanged, but various ways of getting a good load quicker with less rounds down range changes.

The difference between load development for a hunting rifle and F class rifle is the same, just the process should bequicker for a hunting rifle as you typically aren't chasing the tiniest group possible.

I don't like load development so once I get a 1/2 moa load sorted I'm happy. I don't fancy wasting a box of projectiles on a huge seating depth test if I don't need to

-

22-01-2021, 09:28 PM #36Member

- Join Date

- Jul 2020

- Location

- Waikato

- Posts

- 144

Thanks @grandpamac, I have found and read the two parts on 308 last night but can't seem to find the 6.5x55 article. Does anyone have a link they could please share...?

There was something strangely satisfying shooting my own hand loads for the first time last weekend, and fair to say I've now got the reloading bug to go with all the others ... can't wait to load some more rounds for the 308 & hit the hills and get started on a load for the Vixen. This week I was offered an old .303 from a hunting buddy so I may need to pick your brain in the near future.

... can't wait to load some more rounds for the 308 & hit the hills and get started on a load for the Vixen. This week I was offered an old .303 from a hunting buddy so I may need to pick your brain in the near future.

Cheers

Pav

-

22-01-2021, 09:48 PM #37

Hey @Pav, this is the same advice I give to anyone about measuring powder...

Scales come in 3 broad categories - beam scales, strain gauge electronic, and force restoration balance scales.

Strain gauge (aka load cell) electronic scales are the cheaper ones. These drift. You can reduce the drift by letting it warm up, keeping it connected to a stable power source etc.

Electromagnetic force restoration balances cost well over $ 1 K. If you want repeatable accuracy down to 0.1 gr, then this is what you need to look at.

Lastly, the humble beam scale can by surprisingly accurate. One trick with them is to raise the scale to eye level, so that your view of the needle is consistent.

Do some reading about "nodes" and try to find the middle of a node, that way minor errors in powder dispensing will not have a drastic effect.Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

23-01-2021, 08:56 AM #38Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,181

Greetings Pav,

The article showing the graph is in an article called "Managing Component Variations" published March last year. In light of your recent acquisition of a .303 you might also be interested in an article called "Care and Feeding of Old Soldiers" published in May.

One thing I started doing early in my handloading is keeping records.

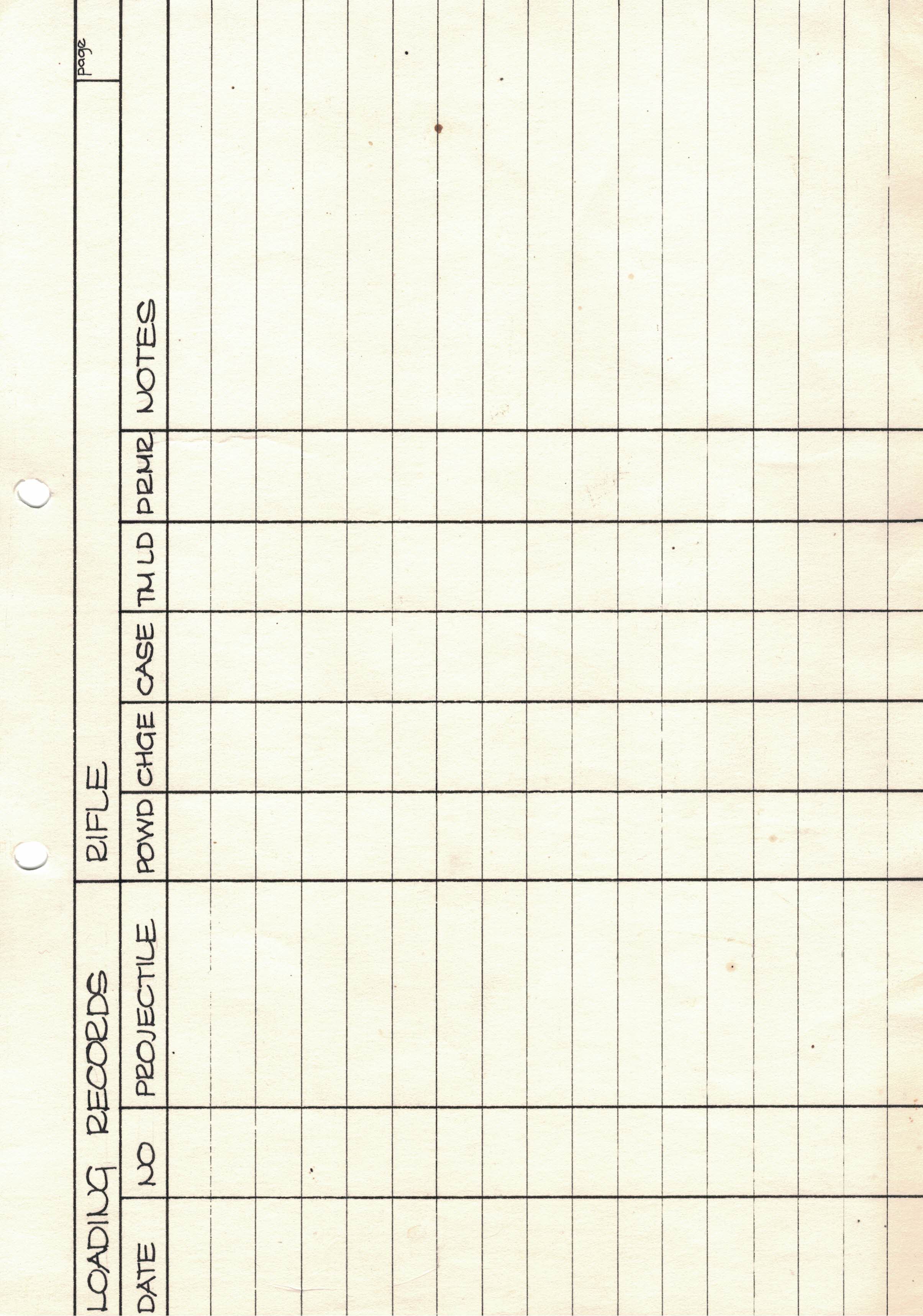

This is a sheet I drew up in about 1978 once I had been bitten by the handloading bug. I was loading for one rifle, a .308 which I still have, and had just started doing my first load development. I gave a copy to a young hunter starting out handloading a few years later and he is still using them. My son uses an improved version. We all keep hard copy data as this remains if your computer craps itself. Some handloaders just write the loads on the box of cartridges but this leaves no permanent record. I started with one ring binder in 1978 and now there are about eight. As well as the load records load data from the internet, some old targets and relevant notes and articles are in the ring binders. Most of my loads are stored in plastic boxes each with a slip of paper recording what they are. You will develop a system of keeping track of things that suits you, earlier would be better than later especially as the number of rifles you load for grows.

Getting back to the original question my first load development I worked up from the Speer mid load of 41.5 grains of IMR4064 behind a 180 grain Norma projectile to the max of 43.5 grains. The steps were one 1.0 grain followed by two 0.5 grain steps. The loads were fired in one session two shots per load. The impact moved up the target and the shots became closer together as the charge increased. Back home the remaining 32 cases were loaded with the top load ready for hunting. This was October 1979 a rather simpler time.

Regards Grandpamac.

-

01-02-2021, 05:32 PM #39Member

- Join Date

- Jul 2020

- Location

- Waikato

- Posts

- 144

Thanks @ebf for the lowdown on scales. I have been looking at different reloading kit options or deciding whether to piece together my own kit with various components from different manufacturers... so from what you've said I would be better going for say a Redding model #2 beam scale over a Hornady g2-1500 or equivalent lyman electronic scale?

-

01-02-2021, 05:38 PM #40

If it was me I would go for the beam scales. Just my opinion, and when it comes to reloading, there are lots of different opinions.

The RCBS scales are good as well, especially if you can find one of the older Ohaus models. I have an old 5-0-5, the 10-10 is great as well.Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

01-02-2021, 06:09 PM #41

If starting out I would go along with the advice of a good beam scale and trickler.

However you will eventually get sick of it in a year or so and go electronic. And if you know what your doing technique wise any of the available models out there now are just as capable as beam scales for reloading real world accurate and consistent ammo.

Sent from my SM-T510 using TapatalkDo what ya want! Ya will anyway.

-

03-02-2021, 02:33 PM #42Member

- Join Date

- Nov 2020

- Location

- Auckland

- Posts

- 656

Similar Threads

-

375 winchster reloading 240 grain lead

By akaroa1 in forum Reloading and BallisticsReplies: 0Last Post: 13-03-2020, 09:07 PM -

.224 Sierra 55 grain varmitters swap for 65 grain gamekings, also some .222 stuff

By Chur Bay in forum Projectile and Factory Ammo ExchangeReplies: 6Last Post: 08-08-2016, 08:36 PM -

Anyone reloading 35 grain 223's ??

By kiwi39 in forum Reloading and BallisticsReplies: 20Last Post: 17-09-2013, 11:48 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

61Likes

61Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks