Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 29 of 29

Thread: Powder coating trays

-

23-07-2021, 11:51 PM #16

-

-

24-07-2021, 10:51 AM #17

Cheers guys, got some of that Eastwood stuff last week but wondered if there was a cheaper supplier around. Going to do some .358 casting this morning. The Mrs wants purple bullets for CAS so that's on the cards too, she even bought the toaster oven.....

-

24-07-2021, 12:23 PM #18Member

- Join Date

- Sep 2017

- Location

- BOP

- Posts

- 513

I've just cast a bunch of 30cal bullets for my 30-30 with a mates Lee pot and molds. It's my first time casting and I haven't lubed and run the casts through a sizer die. This is the first I've heard of powder coating as opposed to lubing with the likes of Lee alox. Are there significant advantages to powder coating over traditional lubing? Do you powder coat and then run the casts through a sizer die afterwards, no lube required?

Thanks, Joel

-

24-07-2021, 01:58 PM #19

Powder coat and then size. Can push a powder coated bullet faster than lubed.

-

24-07-2021, 02:02 PM #20

-

24-07-2021, 03:24 PM #21

-

24-07-2021, 03:32 PM #22

@Driverman I might be over thinking it but…………

The process relies on the initial static process of bonding the powder to the projectile.

This is achieved by using say a number 5 recycling plastic container, shanking and rolling the projectiles sometimes with plastic beads / airsoft pallets.

Would like something like below run against and underneath the container increase or enhance the process????

-

24-07-2021, 04:10 PM #23

I dont use the plastic pellets but just shakenbake the boolits on their own, The airsoft balls are really there to stop the powder being knocked around by the other boolits .I find that I can use just about any type of plastic container but have developed liking for the round chinese takeaways containers. I apply a very thin powder coat and then size and then apply another coat just piling them onto a non stick lined tray. At about 5 minutes baking I give the tray a jumble shake to stop clumping and when baked dump directly into cold water. Another technique I use is to dissolve powder into acetone and when thoroughly mixed lower a tray of boolits into the mix and then lift and allow to dry. The boolits have a very exact thickness of coating and are then baked at 400f for 30minutes. they are extremely accurate .I have found it better to apply a thin powder coat several times than a thick coat. As an example I cast a bore rider 208 grain for one of my 303 that has a bore of .314 and powder coated once and sized .316 shoots about 2" groups at 100yards.(11 grains ap70). two thin powder coats sizing each coating pulls the group into about 1inch and a quarter to 1inch and a half. I only use the translucent copper for this load which I have been told by Smoke is no longer available. .I have also developed a high pressure coating using powder and then coat with an invisible carnauba /lithium wax for +p 9mm etc. I am getting groups at 50 yards that show promise. I have all the time in the world to play around with coatings and enjoy shooting cast boolits .

I am now heading off to my reloading room to load some 32S&W long with some 98g powder coated wad cutters. I have to develop a new load for these as the powder coating is so slippery I am getting inconsistent accuracy ,I think due to low chamber pressure .I will up the charge by .1 of a grain. You have to draw a balance between crimping and powder loadings because crimping altho it increase chamber pressure causes boolit deformation.

-

24-07-2021, 04:19 PM #24

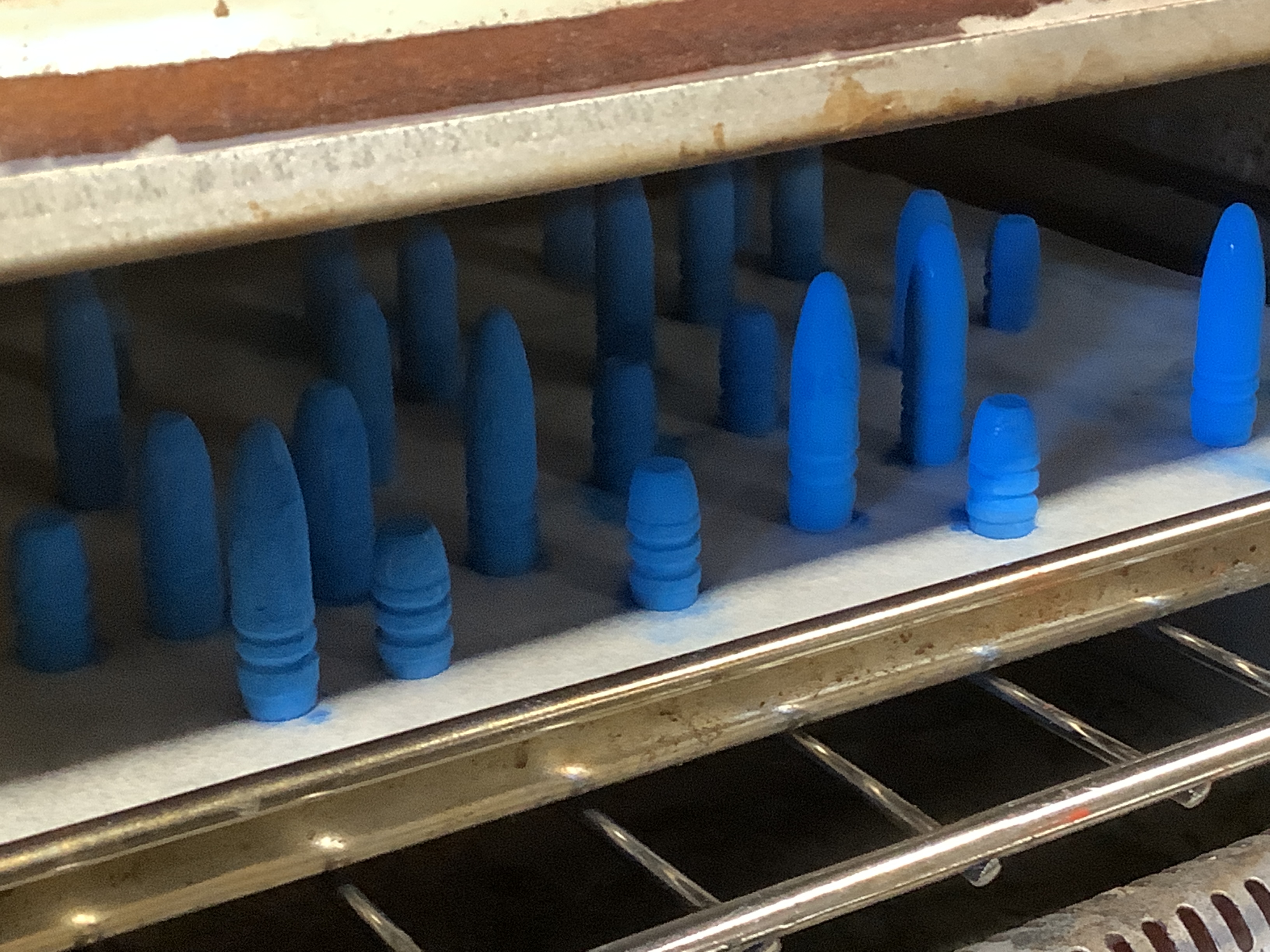

Ive just put in another lot to be baked, including previously poor coatings, its also interesting that certain projectiles seem to like the powder????

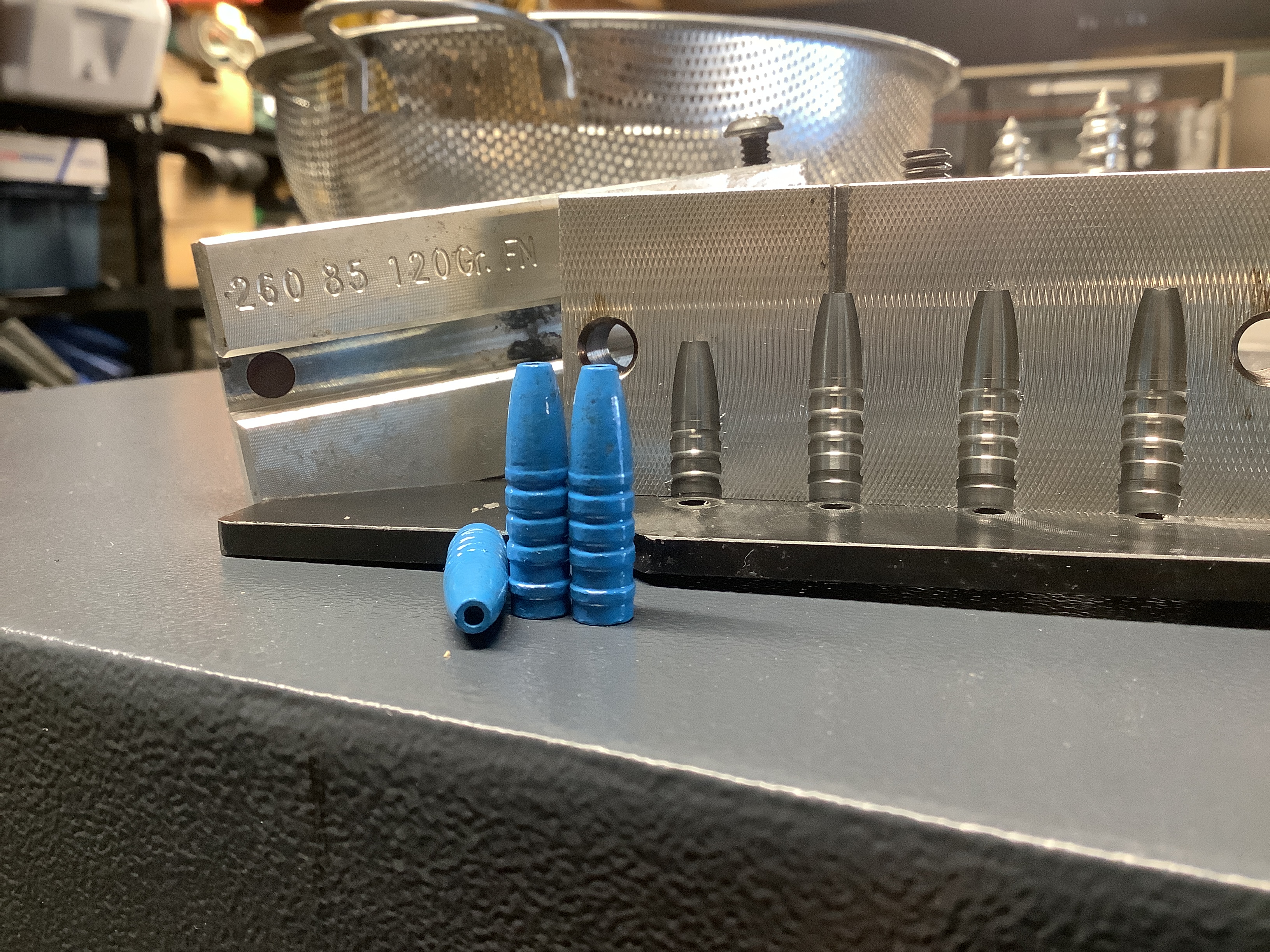

The lot just out

-

24-07-2021, 05:51 PM #25

@Driverman you’ll appreciate the mold….yes a purchase through the cast boolits forum some years ago, this means I might get the 25/06 out again!

-

24-07-2021, 09:12 PM #26

Achievement for the day, not the most uniform coating but good enough for close pistol targets.

-

24-07-2021, 09:32 PM #27

we'll have everyone casting and powder coating before to long

-

24-07-2021, 10:35 PM #28

-

24-07-2021, 11:09 PM #29

Trial and error, plus a bit of youtube. Heat them a bit before adding powder, just not too much as it gets too sticky.

Similar Threads

-

Powder coating projectiles

By R93 in forum Pistol ShootingReplies: 14Last Post: 05-11-2023, 10:54 AM -

Hi tek coating

By marky123 in forum Pistol ShootingReplies: 3Last Post: 15-12-2016, 12:21 PM -

Lee Hand Primer trays ?

By Frogfeatures in forum Reloading and BallisticsReplies: 3Last Post: 17-04-2016, 11:10 AM -

Removing powder coating?

By Wildman in forum Projects and Home BuildsReplies: 6Last Post: 09-12-2012, 09:00 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks