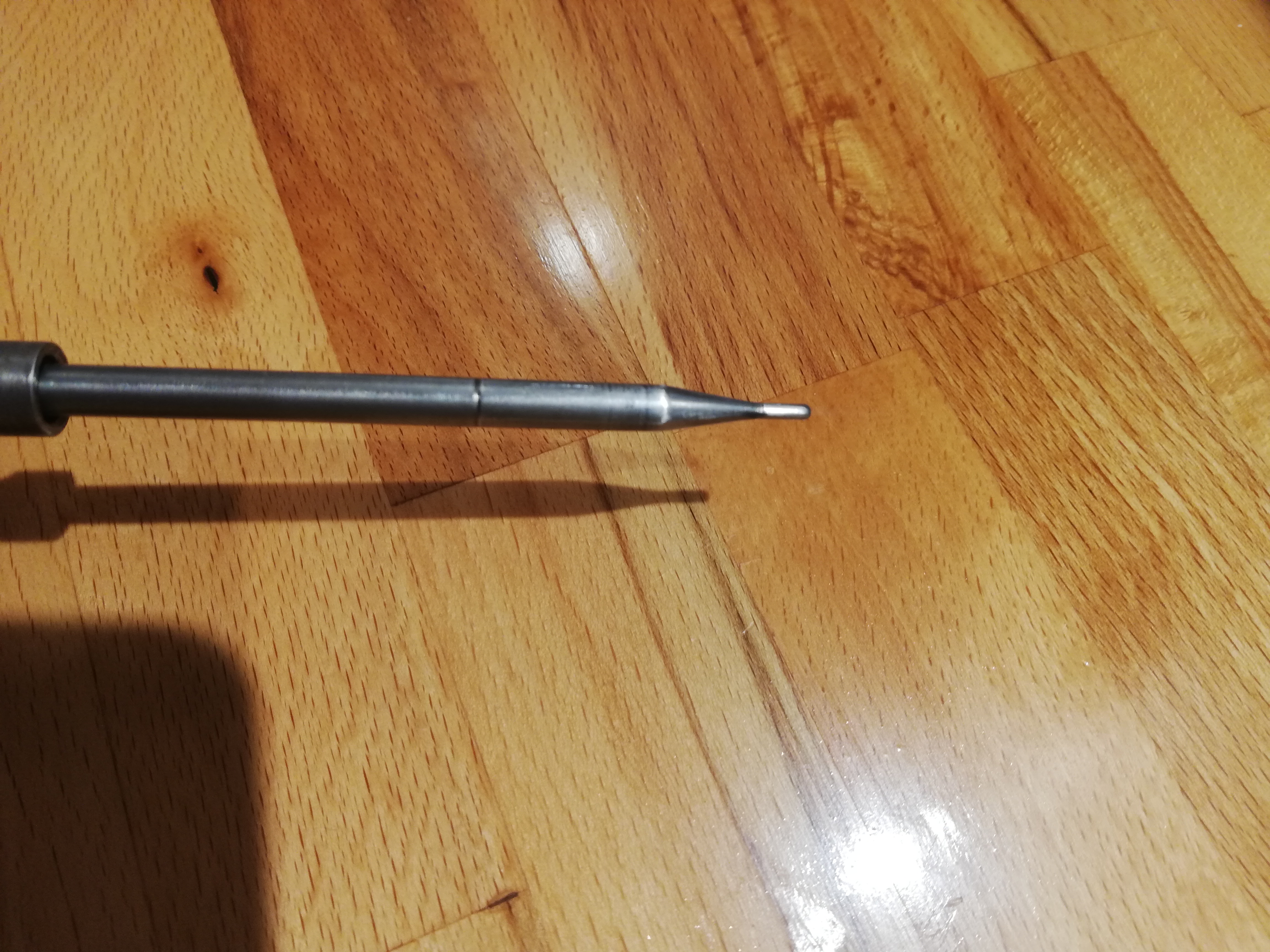

That sir is a rusty firing pin.. that bush at the end of the spring should be shiny and smooth, it runs on the inside surface of the bolt which Im guessing also looks like that rusty mess. Look down inside the bolt with a torch.. clean and polish with some wet and dry paper then lightly grease the contact surfaces when refitting.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 43

Thread: Primer issues

Hybrid View

-

24-11-2018, 06:19 PM #1

-

24-11-2018, 05:44 PM #2

Could just be bad luck like you say. But looking at the pics, looks like it's got some heavier-than-necessary grease on it. Light lubricating oil is all you need there unless you do trench/jungle warfare.

While you have it out, I'd clean it all completely with CRC, get some 2000 grit abrasive paper and give all the gliding surfaces a mirror shine finish. The gliding surfaces include the pin portion riding inside the spring and the surfaces supporting the ends of the spring (springs often want to twist/untwist in compression/decompression and there is friction at the ends too therefore). That is, if you can dismantle them. I'd check with a vernier gauge how much the pin normally protrudes, in case you inadvertently alter that on disassembly/reassembly. Whether or not you go for a polishing job, it must be clean as inside a sewing machine inside a rifle bolt.

This video conveys the general idea, except I'd use 2000 grit paper.

An itch ... is ... a desire to scratch

-

24-11-2018, 06:20 PM #3

two things....... get a lee hand primer so you can "FEEL" the primers bottom out in pocket

release your bolt when you put it away eg turn the end so fireing pin/spring is in relaxed position.......this has bonus that it WONT go back in rifle untill you turn it back again.my .223 did this heaps when new...havent had any issues for 15plus years since doing this.

-

24-11-2018, 07:58 PM #4

That pin could do with a little love, put it on your maintenance list but I dont think that's the cause. Do you Full lenght size the cases? and if yes how did you set up the sizing die?

Just a slopy retrobate

-

24-11-2018, 09:19 PM #5Member

- Join Date

- Aug 2012

- Location

- helensville nz

- Posts

- 4,707

Ya brass could be fucked bro or bad batch

Normally it would be impossible to seat to deep as the primer bottoms out on the bottom of the primer pocket

The primer pockets on brass Very between brands/batches

But aslong as they are flush with the head or only a thou or 2 below flush

All good

Well that’s how i see it

-

24-11-2018, 09:25 PM #6

When the rifle is cleaned and reassembled I suggest you seat some primers in empty, sized cases and test the fall of the pin to see what kind of prints it's leaving.

-

25-11-2018, 05:47 AM #7Member

- Join Date

- May 2016

- Location

- carterton

- Posts

- 1,045

When you reprime the cases do not touch the primers as a sweaty or oily finger can desentise the primer. As an earlier post said, use a lee priming tool.

-

25-11-2018, 11:48 AM #8Member

- Join Date

- May 2015

- Location

- Nz

- Posts

- 3,040

Argh shit. That could definitely have been an issue then with touching the primers

-

25-11-2018, 12:09 PM #9

I just came back to the thread to see an after-picture of your mirror shine firing pin.

The rusty firing pin is a confirmed issue with your rifle, the rest of the discussion above is qualified guesswork.An itch ... is ... a desire to scratch

-

25-11-2018, 07:30 PM #10Gone but not forgotten

- Join Date

- Apr 2017

- Location

- Hamilton

- Posts

- 4,129

According to my Nick Harvey manual you can seat primers to deep, which can crack the pellet of primer compound and cause inconsistent ignition.

In some brass my primers are flush with the base, in others they are slightly, but noticeably, deeper. I use a hand priming tool, much better "feel" for when the primer is seated. I didn't get a Lee one though, as they require special shellholders, and I'm a tight-arse! The standard Lee shellholders don't work in my one either, too thick for the seating plunger.

-

25-11-2018, 08:53 PM #11Member

- Join Date

- May 2015

- Location

- Nz

- Posts

- 3,040

@Cordite all nice and shiny now. Will try put some rounds through before the weekend (the ones where I feel the primers are seated too deep) and will report back

@Cordite all nice and shiny now. Will try put some rounds through before the weekend (the ones where I feel the primers are seated too deep) and will report back

-

25-11-2018, 09:00 PM #12

I got me one of these K&M primers bloody good bit of kit takes the guess work out of seating depths!

It's all fun and games till Darthvader comes along

bloody good bit of kit takes the guess work out of seating depths!

It's all fun and games till Darthvader comes along

I respect your beliefs but don't impose them on me.

-

26-11-2018, 12:31 PM #13Member

- Join Date

- Jul 2012

- Location

- Tauranga

- Posts

- 2,632

Do the firing pins on tikka's rust more than other styles? Is it down to the amount of body fluids injected into them?

My opinion is that the primers are a wee bit proud on the misfire cases.

-

26-11-2018, 04:05 PM #14

T3s have been the worst Iv seen. The ones with misfires had rust build up on the taper to the point that it was jamming in the bolt body creating light strikes. Id guess its a combination of the steel tikka have used coupled with a thought process that being a stainless rifle it doesn't need maintenance. Finding the cause of miss fires is a process of elimination. A good look at the primres that failed should show either a good or a light strike. If its a light strike with T3s the most likely is a rusted firing pin but superdivers dosnt appear to be the problem here. Next Id check the sizing process, if the shoulder is bumped to far the case will have to much room and not hold firm against the pin strike. If the crater looks good like its had a good strike then primers can be an issue but its rare and 2 in a row seems even less likely. Im not a believer in the not handling primers thing. While oils etc can make a primer inert its very difficult to get enough oil off your hands with normal handling, maybe if you use to much hair gel and you are preening while priming? Brass can be the cause, iv seen the odd case with no flash hole or a bad pocket but again 2 in a row pushes that idea down the list a bit for my way of thinking.

It could be anyone of the above or something else like meths or solvent getting on the primers somehow, a bit of crap in the bolt body, the bolt not closed properly and closing /firing almost in battery which gives light strikes.

It may be something that doesn't raise its head again and youll never know for sure what caused it.Last edited by sneeze; 26-11-2018 at 04:33 PM.

Just a slopy retrobate

-

26-11-2018, 05:37 PM #15

Going by the pictures, the firing pin was certainly not manufactured with a mirror shine surface, which left it less protected against corrosion.

It reminds me of building houses with nearly flat roofs, thinking one has great modern building materials that will do it all -- instead of just putting a decent slant on it. Likewise, "stainless" does not equal "stainfree", and giving stainless a mirror shine (think of your Swiss army knife) +/- followed by passivation seems worthwhile on such important components. But this is a compromise between mass production needs, cost, and what you want for your own gun. The 2000 grit wet and dry is definitely worth a go.An itch ... is ... a desire to scratch

Similar Threads

-

Small primer vs large primer brass in 308

By Cowboy06 in forum Reloading and BallisticsReplies: 5Last Post: 02-12-2017, 09:57 AM -

Best Primer?

By Wildman in forum Reloading and BallisticsReplies: 14Last Post: 02-06-2014, 06:56 PM -

magnum primer v large rifle primer

By mucko in forum Reloading and BallisticsReplies: 19Last Post: 17-01-2013, 09:32 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks