Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 41

Thread: RCBS Dies... Problem?

-

27-06-2017, 11:15 PM #16Trust the dog.........................................ALWAYS Trust the dog!!

-

-

27-06-2017, 11:19 PM #17northdudeGuest

are you lubing the entire outside of the case

-

27-06-2017, 11:25 PM #18

Do your fired cases, prior to sizing chamber easily Ryan?

If so back the die off the case holder a turn and size another. Could be out of spec lengthwise or your case holder is out of spec causing too much shoulder bump. You should be able to see how far your neck is sized by eye if you have backed off too much.

Sent from my SM-G935F using TapatalkDo what ya want! Ya will anyway.

-

27-06-2017, 11:54 PM #19

Prior to sizing they all chamber fine, they were all new norma cases and have only been fired through my rifle, they were originally sized and loaded through Hornady new dimension dies. I never had a problem with the same once fired brass when I ran it through the Hornady dies, it ran in and out of the die nicely and chambered nicely once loaded

-

28-06-2017, 08:18 AM #20Member

- Join Date

- Feb 2012

- Location

- hokitika

- Posts

- 1,476

Back your die off

Sent from my iPhone using TapatalkDont waste your time chasing every last fps, it doesnt matter in the real world, it wont make a difference, all it will do is cause head aches and frustrations. And dont listen to silly old cunts

-

28-06-2017, 09:05 AM #21

Don't know why the RCBS dies should be tight near the base. I would be doing a check with an inside mic but unfortunately you no longer have your old dies to compare. And if there are problems closing the bolt after FLSing I would suspect excess sizing of the body has pushed the shoulder fwd and the die need adjusting down not up. With a cheap set of Hornady gauges you can measure to the shoulder datam point and know exactly the issue. You could also use the old felt tip pen trick and paint some stripes the full length of the case and then see where the rub marks are.

-

28-06-2017, 09:08 AM #22

Check you case overall length unsigned and sized - when you locate your vernier ha ha. This will tell you how much you are working the cases.

-

28-06-2017, 09:35 AM #23

Ha Ha. Sorry Ryan. No wonder I was miffed.

Go with what Zimmer has posted. I use a forster press so my upstroke is your downstroke (wish I could find better words😆

I'm all back to front. But that's not new.

Sent from my SM-G935F using TapatalkDo what ya want! Ya will anyway.

-

28-06-2017, 09:14 PM #24

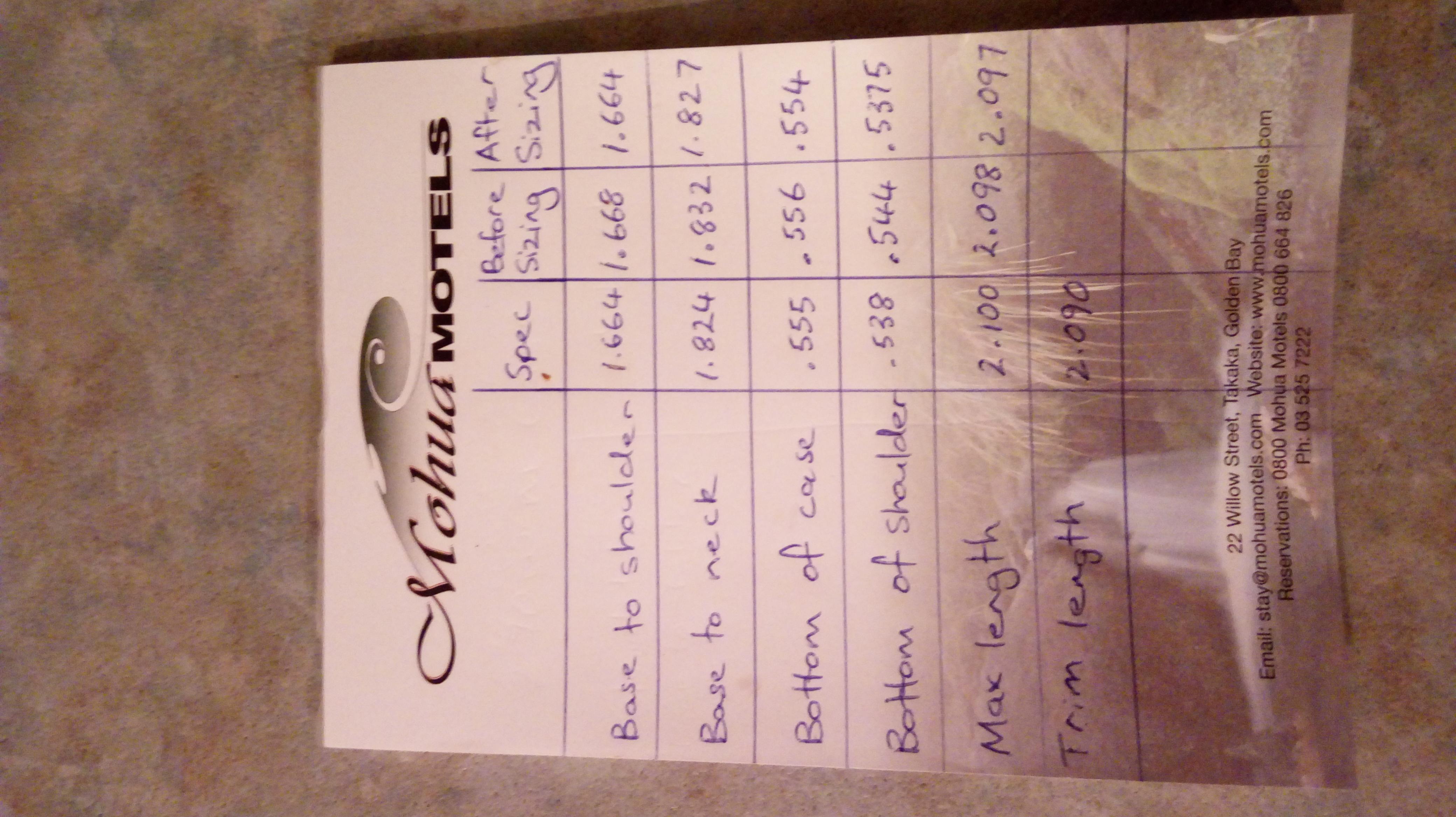

So i managed to pick up a new caliper today and just had a measure up, the dies seem to be sizing the brass to spec pretty good, and the brass doesn't seem to be getting excessively stretched during firing, only thing I can see is im approaching max length and due for a trim (never checked case length before first loading, just sized and chamfered then loaded, so they could have been long to begin with) im miffed as to why its taking so much effort to do so little sizing?

-

28-06-2017, 10:04 PM #25Member

- Join Date

- Apr 2012

- Location

- Bay of Plenty

- Posts

- 391

Lube?

Sent from my GT-I8190T using Tapatalk

-

28-06-2017, 10:21 PM #26Member

- Join Date

- Feb 2016

- Location

- Stewart island / canterbury

- Posts

- 9,193

Getting weak... More weetbix

-

28-06-2017, 10:21 PM #27

I would say your new dies have a smaller body and base dimension than your old ones, this will cause tight sizing that last few mm as it is squeezin the whole body and base in smaller, this should make em chamber more easy but that brass has to go somewhere and it goes forward and pushes the shoulder forward, this should show as easy to chamber but hard or impossible to close bolt, check with vivid or some marker where the empty sized case is binding on the mouth/neck/shoulder and body.

Necks generally can be quite a bit longer than SAAMI spec in a SAAMI spec chamber but if that is the cause trim, if not then most likely the shoulder has moved forward, on the same case wind down an 1/8th of a turn until it will chamber with the slightest resistance on bolt closing=Zero headspace go down max 1/8th turn more and test another couple of brass and if all good you should be all set up, recheck for any sign of excesses case length."Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

28-06-2017, 10:28 PM #28

-

28-06-2017, 10:32 PM #29

What do you man by wind down VC? Wind the die down further? I have it setup so that shellholder stops on bottom of the die as per instructions with the dies... They seem to be sizing to spec well I just cant understand why I nearly have to rip my press off the bench especially when they are not stretching much during firing so the die isnt actually doing much sizing really.

-

28-06-2017, 10:41 PM #30

You are hitting the case holder while on the sizing stroke with a case being sized?!?

First ascertain where the case is stopping you chambering it, if it is at the mouth all good trim, if it is at the shoulder your die needs to go down, die setting instructions are shit....dont set to touch the case holder set to match your rifles chamber lenght/headspace.

If it is tight on the shoulder the die needs to go down, if it is kissing the shell holder WHILE SIZING the case you need to remove some of the die from the bottom.

presses stretch and kissing the holder with no case can be miles of with a case."Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

Similar Threads

-

FS 300 win mag RCBS dies

By HUNTY in forum Projectile and Factory Ammo ExchangeReplies: 1Last Post: 27-11-2017, 09:41 PM -

RCBS Chargemaster 1500 problem??

By Baz in forum Reloading and BallisticsReplies: 75Last Post: 10-10-2012, 09:49 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks