you wont find the perfect woman, I married her.... Ive always noticed on gun forums that one of the few threads that stays on course on them are 22 hornet threads

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 76 to 90 of 100

-

18-08-2024, 02:07 PM #76Member

- Join Date

- Jun 2023

- Location

- waimakau

- Posts

- 4,396

may be sarcastic may be a bad joke

-

-

18-08-2024, 02:16 PM #77

Hugh... While you have your case head in attachment in the drill for checking length and trimming....grab a new Scotch Brite cloth and hold against those dirty cases.brings them back to shiney in no time at all. If you don't have the LEE case trimmer set. Just buy one...soo plurry easy to use.

75/15/10 black powder matters

-

18-08-2024, 11:22 PM #78Banned

- Join Date

- May 2022

- Location

- Ngaio, Wellington

- Posts

- 568

So like I said earlier, perfect weather for reloading!

So I set myself the objective of cleaning, tumbling, FL resizing and depriming all the 22 Hornet cases I had lying around.

In total I've processed 737 cases; 146 Winchester, 240 Remington, 69 Norma, 282 Hornady.

Part of the motivation was to answer the question, "How many split or head separation case do you get?" This follows on from the above thread.

The answer is, out 737 cases I found SIX with neck splits and ZERO head separation (I didn't check inside any cases with the bent paper clip).

Brand of the six split case: 5 Remington, 1 Winchester.

I expected the Winchester to be the split, and only split, because some of that brass dates back to 1988 when I bought my first Hornet.

I've said this before, I don't chase the holy grail of 3000 plus feet per second. I don't load to maximum.

My only grail is a thumb sized group at 150m and instantaneous clean kills. I don't want to unzip a rabbit from it's arse to it's brisket, because I want to be able to eat the livers and kidneys, so I don't want to cover those in shit! To me a good projectile/load combination makes a neat entry hole and an exit hole about the size of your thumb or a golf ball.

If you fellas are getting a lot of splits and head separation, you need to revist you processes, check that your rifle chamber isn't stuffed, and stop chasing maximum.

On process. This weekend I started washing fired cases in boiling water, with a dollop of dish washing liquid. I don't wash each individual case, just slosh them around in a bowl. Reason being, I read, perhaps on this forum, that the troops used boiling water pouring down the barrel to remove powder foiling. I now know from experience that the water in the bowl turns dark grey, so it is obviously dissolve powder residual. Then I stand them in a grate, vertically to drain and dry over the fan heater. Once dry they going into the walnut tumbler. Interestingly the cases cleaned with boiling water, go through the FL resizing die more smoothly and easier. Perhaps with the neck clean of powder residual the neck sizing ball isn't getting stuck.

Some people say cleanliness is next to Godliness, but I reckon cleanliness is next to accuracy.

-

19-08-2024, 12:18 AM #79

I just run cases for about 3-5 minutes in a cheap ultrasonic cleaner after depriming.

About 75% water 25% vinegar plus a squirt of dish washing liquid. Come out clean, but not shiny.Hunt safe, look after the bush & plug more pests. The greatest invention in the history of man is beer.

The greatest invention in the history of man is beer.

https://youtu.be/2v3QrUvYj-Y

A bit more bang is better.

-

19-08-2024, 12:22 AM #80

Maybe your hot water is doing a gentle anneal??? After all a round in dishwasher will poke the temper of a good knife.... And I agree trying for last fps is pointless.lots of reloading manuals tell us that very thing.

75/15/10 black powder matters

-

19-08-2024, 04:13 AM #81Member

- Join Date

- Mar 2013

- Location

- Bell Block NZ/Northern Alberta Canada

- Posts

- 1,160

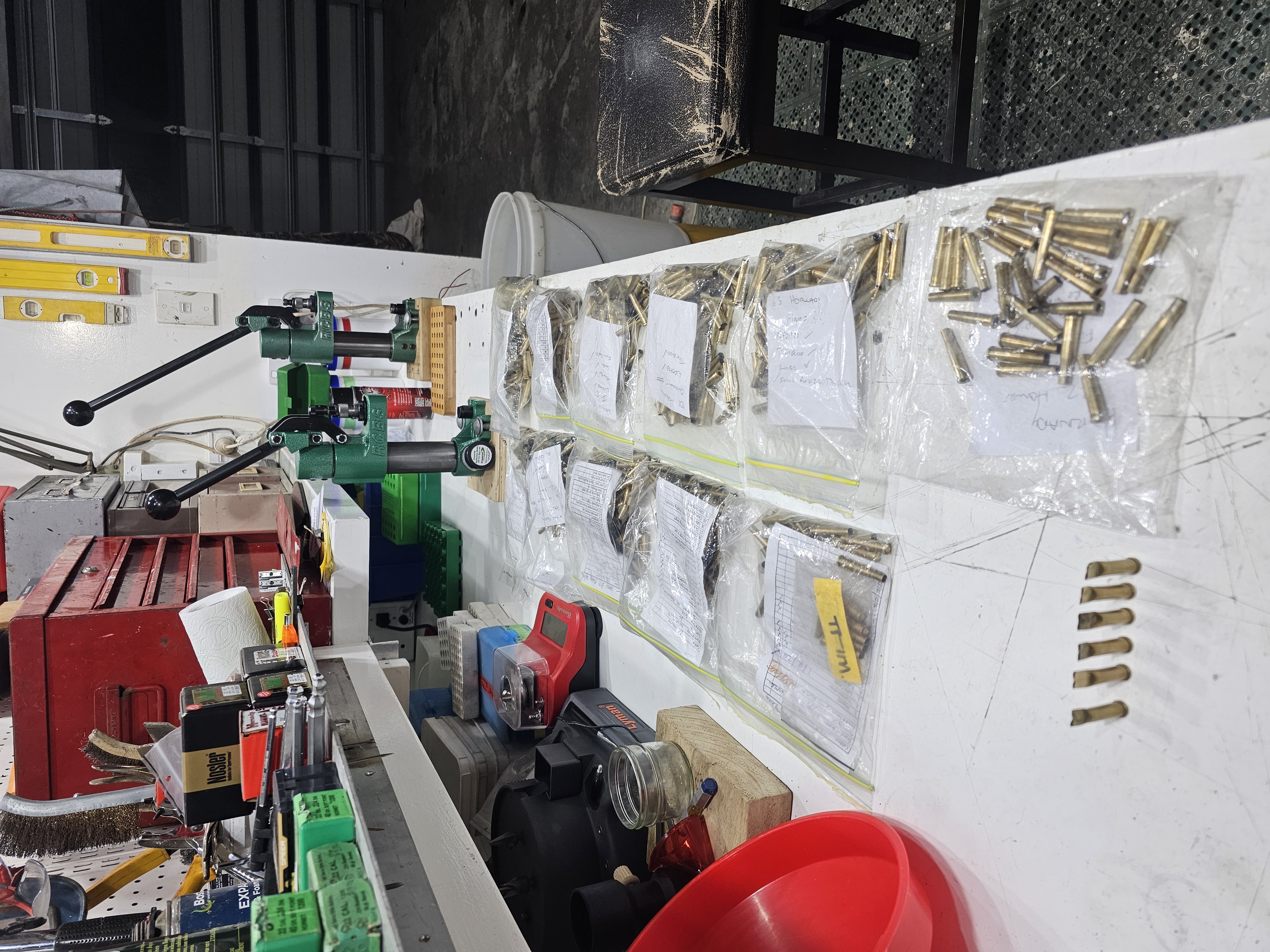

Well seen as Hugh and i have been loading, .22 Hornet, the last few days, out last night at the range, running loads threw 3 K95 barrels and checking speeds,

Was given a box of 50 home loads, with Remington brass, WSR and 10gr 4227 under a 45gr bullet, these shot well, and are at 2500fps, My mango speed was unable to pick up the 46gr trail boss loads,

Sighted in another compact scope, for the reduced loads, The joy and expense of a Blaser quick change system.

I tried Sum more of the 40gr Fox bullets, with old brass, unfortunately another case head separation, on second shot, this is the round shown, two pages back, "Grr" I debated scraping it, and did try to pull bullet, but cought not, get enough grip, to pull, speed 2650 fps.

Sum interesting results, with the .243 K95 barrel, low to mid loads, showing book and quick load. at 3000 fps, are running much higher, 300-350 higher with 85-90gr weights. very Fast barrel.

Put sum Images up showing new cases and cases showing separation lines, I now have a Redding neck sizing die, and have not got any lines/problems, on another other brass just the original 25 Hornady that I am running to destruction to see how much life i can get. have dropped loads back from original 12g LG, now 11.5 with 40gr, next batch or 45 i might load lighter, and intend to try a few loads with CFE Blackout, this works great in my 17 Hornet.

sure like this little break action single shot Blaser, very fun gun in .22 Hornet,

![Name: IMG_2379[1].JPG

Views: 93

Size: 3.86 MB](https://www.nzhuntingandshooting.co.nz/attachments/f10/257517d1723993464-reloading-22-hornet-original-%96-optimal-canada-goose-load-img_2379%5B1%5D.jpg)

![Name: IMG_2380[1].JPG

Views: 95

Size: 2.35 MB](https://www.nzhuntingandshooting.co.nz/attachments/f10/257518d1723993481-reloading-22-hornet-original-%96-optimal-canada-goose-load-img_2380%5B1%5D.jpg)

Last edited by southernman; 19-08-2024 at 04:20 AM.

-

19-08-2024, 04:18 AM #82Member

- Join Date

- Mar 2013

- Location

- Bell Block NZ/Northern Alberta Canada

- Posts

- 1,160

Not sure, if its been said in this thread, but hornet brass had large variations in Capacity, Remington and Winchester brass, has at least a grain more, than Hornady or PPU for example, this is about 10%.

Easy to over pressure, with wrong load, in small capacity brass.

-

19-08-2024, 03:50 PM #83Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,620

So I thought the troops put hot water thru the bore of their battle rifles to rid them of the salts from ye old corrosive military powders, including BP, and primers. Yes? I doubt it does any harm with modern smokeless powders and non-corrosive primers, may even do good but hardly essential. Not sure I'd bother but keen to hear your verdict. I've never done more than rely on my corn media case tumble for bulk. And for small batch rifle I just brush the neck out and clean the primer pocket of soot. But then I'm not a distance accuracy hound

I know a lot but it seems less every day...

I know a lot but it seems less every day...

-

19-08-2024, 04:10 PM #84Member

- Join Date

- May 2012

- Location

- Sydney

- Posts

- 1,808

Reloading 22 Hornet (The Original) – Optimal Canada Goose Load

Correct, Boiling water was used to flush the corrosive salts of mercuric primers.

Sent from my iPhone using Tapatalk

-

19-08-2024, 05:24 PM #85

Black powder gets the hot water treatment too or corrosion sets in very quickly.

75/15/10 black powder matters

-

19-08-2024, 06:16 PM #86

@Hugh Shields, the k hornet has been sitting at Alan Carr's since before his accident. Diagnosis was when it was rechambered the reamer was slightly off centre. Cutting the chamber off and re chambering it was the intended fix, but whenever that happens is up in the air.

-

19-08-2024, 07:46 PM #87Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,993

I dunno about the dishwasher stuffing the temper of a knife - after all cutting up a freshly cooked chunk of meat is hotter than the dishwasher and knives handle that fine... I think the knife in the dishwasher thing is from getting tapped onto other objects in the water splashing and spraying about?

-

19-08-2024, 07:54 PM #88

Could be the acidic chemicals too but pretty sure it's the super hot then cold water thing... One thing for sure. You can pick knives that have been through them. Steel is hard and getting that last degree of sharp is troublesome.

75/15/10 black powder matters

-

19-08-2024, 08:31 PM #89Member

- Join Date

- Jun 2023

- Location

- waimakau

- Posts

- 4,396

-

19-08-2024, 08:37 PM #90

Many years ago I was desperate to buy a Hornet. But it never happened.

A few years ago purchased a Marlin x7 223, and glad I did.

When ever I read about loading the Hornet there seems to be case issues, e.g. split necks etc.

I reckon it's mainly a case design issue.

Brass doesnt just go brittle with age. However case corrosion over say 20 years has always been an issue. Dampness, and exposure to various substances such as ammonia causes it I believe.

Hot water will not change the temper of steel, nor will it anneal brass, even the slightest.

Just my 2cHunt safe, look after the bush & plug more pests. The greatest invention in the history of man is beer.

The greatest invention in the history of man is beer.

https://youtu.be/2v3QrUvYj-Y

A bit more bang is better.

Similar Threads

-

Canada goose Pastrami

By Marty Henry in forum Game Cooking and RecipesReplies: 3Last Post: 04-02-2017, 10:02 AM -

e-can -canada goose problem

By kotuku in forum Game Bird HuntingReplies: 5Last Post: 04-02-2016, 07:07 PM -

Canada Goose

By Dundee in forum Photography and VideoReplies: 3Last Post: 28-08-2013, 09:09 PM -

Canada goose calls...how big are they?

By EeeBees in forum Game Bird HuntingReplies: 9Last Post: 06-06-2013, 07:26 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

93Likes

93Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks