It's sometimes recommended that we sort new brass by weight and either batch them for use or discard outliers. Fred Sinclair and Bill Gravatt [ref 1], expected to reject about 25% on visual inspection, then aimed for a total weight range of < 1.5% across their working set of brass. They said to do this before any length trimming, flash hole or primer pocket uniforming.

I checked my batch of 200 new Lapua 6.5 Grendel cases:

I couldn't see any visible defects like neck damage, dents, chips or flash hole burrs.

Weights

Case Wt (gr) Number of Cases

110.0 2

110.1 4

110.2 7

110.3 9

110.4 9

110.5 9

110.6 10

110.7 21

110.8 26

110.9 24

111.0 23

111.1 24

111.2 17

111.3 9

111.4 4

111.5 2

Total range: 1.5 gr = 1.5%

By culling away the 22 cases <= 110.3 and >= 111.4, all remaining cases were within a range of 1.0 gr.

Would it have been better to size and trim them all to length, ream flash holes, deburr them and cut the primer pockets before weighing ?

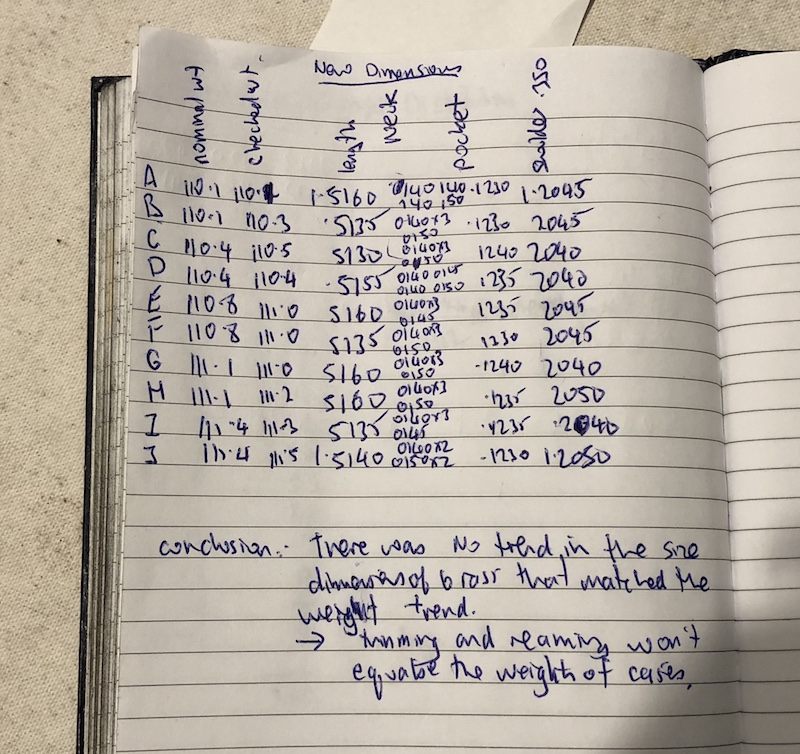

So, I measured a selection of 10 cases having a range of weights to see whether perhaps the heavier ones were so due to being longer or perhaps the neck thickness would be the cause of heavier or lighter brass overall. There could be other dimensions that might be of interest - suggestions welcome ! Also suggestions and critique of the correct way to measure these dimensions, please .

Measuring neck thickness at 4 places:

I found that most measurements were 0.0140" (measuring to 0.0005") and most cases had one, sometimes two quadrants which were +/- 0.001".

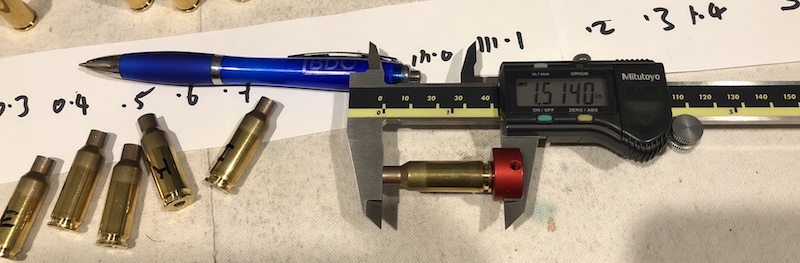

Measuring cartridge length:

Lengths ranged from 1.5130 to 1.5160" and there was no trend with weight.

SAAMI 1.500 - 1.520"

Checking cartridge headspace dimension on the shoulder at 0.350" diameter.

This is a Hornady Case Headspace guage.

Range 1.2040 - 1.2050"

SAAMI 1.213 - 1.220"

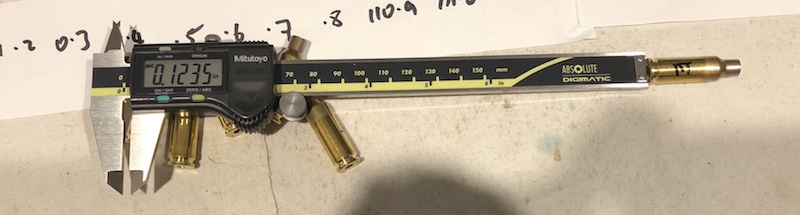

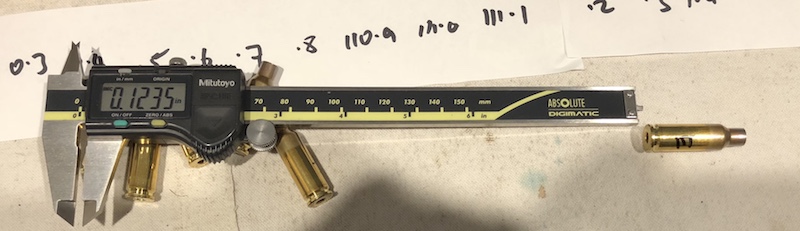

Primer pocket depths (best of 3 for each case)

I used the end of the slider shown on the right of this photo.

0.1230 - 0.1240"

SAAMI 0.117 - 0.123"

Here is the summary in my log book:

I reweighed the cases and found they came back +/- 0.1 gr.

My conclusion was that variations in case dimension didn't explain the variation in weight, so trimming and pocket cutting wouldn't normalise the weights of otlier cartridges. I also doubt whether traditional case prep like cutting the pockets, trimming to length, chamfering case mouth or flash holes is actually beneficial on new brass.

I'm wondering what is current thinking on preparing new brass, nowdays ?

ref 1 Sinclair F, Gravatt B "An overview of reloading for extreme accuracy" in Brennan D The Precision Shooting Reloading Gide Precision Shooting Inc 1995.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 5 of 5

Hybrid View

-

24-06-2018, 10:34 PM #1Member

- Join Date

- Mar 2012

- Location

- Waikato

- Posts

- 2,185

Size and Weight Sorting For New Brass

-

25-06-2018, 12:42 AM #2Fulla

- Join Date

- May 2012

- Location

- Cni

- Posts

- 1,660

Is that like a br case?

Good brass like lapua is pretty good. I have done all that but it didn't make any noticable difference to me, then you will need to weigh projectiles, if all the hype is to be believed. Sure sometimes I cull the extremes if I'm wanting to rule out all possiblities however.... For me what I found more important was neck thickness, turning, tension, anealing, seating, concentricity and a good rifle.

A well developed load you won't notice a slight difference in case volume, let's say a few kernals of powder.

I use a neck thickness gauge I think it's called, but it takes a consistent feel for it.

-

25-06-2018, 07:58 AM #3

You were lucky to only 1.5 grains over 200 Lapua Grendel cases, they normally go from 110.1 to 112.2 for me, I have found the Norma brass to be way more consistent

For what its worth I have had 100 Petersen 375 Cheytac brass that only had 2 grains weight spread & it weighs over three times as much

For my Bench Rifles I like to have cases with 0.1 to 0.2 weight spread, less is more, not easy when I use 50 cases for a barrel.

I really need to grab the opposite extreme rejects, prep them, shoot them & compare them to the "perfect" case groups...might save a heap of time & hassle Contact me for reloading components, brass, projectiles, powder, primers, etc

Contact me for reloading components, brass, projectiles, powder, primers, etc

http://terminatorproducts.co.nz/

http://www.youtube.com/user/Terminat...?feature=guide

-

25-06-2018, 07:53 AM #4

If you are weight sorting to check case volume, then shouldnt you actually check the volume?

Has anyone seen results from where checked both weight and volume of each case?

-

25-06-2018, 08:51 AM #5

When I last loaded up some Grendel, I weighed the completed loads for curiosity and found up to 1.5gr difference. So I randomly checked my Lapua brass and found similar results to you. I was surprised about that much variation from Lapua

Since mine is for hunting and they all grouped well, I didn't bother with it any further.

With new brass, I only chamfer, size & load.

Similar Threads

-

Bullet weight sorting

By Dermastor in forum Reloading and BallisticsReplies: 32Last Post: 28-05-2018, 05:42 PM -

Sorting 22lr

By 223nut in forum ShootingReplies: 32Last Post: 26-07-2016, 05:51 PM -

New Brass - do you full length size it?

By WillB in forum Reloading and BallisticsReplies: 23Last Post: 15-03-2016, 05:15 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks