I had a similar issue with a 7mm08 hornaday FLS die, was not bumping the shoulder back far enough(even though it was wound hard down)

I cut a small peice of coke can and put it between the case and shell holder when sizing, still a bit tight but much better.

Funny enough though my mate 7mm08 never had a problem with the stuff.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 43 of 43

Thread: tight closing the bolt

-

13-02-2022, 11:07 AM #31Member

- Join Date

- Jan 2018

- Location

- Helensville, Auckland

- Posts

- 473

-

-

13-02-2022, 11:29 AM #32

-

13-02-2022, 12:10 PM #33Member

- Join Date

- Jan 2018

- Location

- Helensville, Auckland

- Posts

- 473

I put the spacer between the bottom of the case and the shell holder to get the case deeper into the sizing die

@Micky Duck

-

13-02-2022, 12:15 PM #34

Nah MD he's talking about lifting the case up in the shellholder using a shim. Depends upon some slack being present. Some brands of shellholders have more slack than others.

The easiest non fiddly way to do it is to push in an appropriate sized feeler gauge under the case base.

-

13-02-2022, 01:02 PM #35

-

13-02-2022, 02:35 PM #36

I've found that forming the so-called "false shoulder" by going up just one calibre has never been sufficient. Grandpamac's use of 35-cal for .280 would do the job, though the brass in the necks is going to get a good work-out, perhaps 8mm might be a good compromise. My experience has also been to NOT anneal prior to the fireforming and so soften the false shoulder — leave it at as hard a temper as possible, and hope that the necks and shoulders survive being taken up in diameter, back down, and then finally fireformed. But then anneal immediate after the fireforming is done and before asking any more of the neck brass.

-

12-08-2023, 04:15 PM #37

-

21-08-2023, 09:02 PM #38Member

- Join Date

- Mar 2018

- Location

- Fielding-ish

- Posts

- 572

And All shell-holders are definitely-not created-equal . I have had to carefully-remove material from the-top of a holder to make it work , It pays to have a selection of them if possible . Some are very-loose with too-much sideways-play also and can tear the (rimless) rim, leaving a destroyed-case stuck in the Die . Polishing and cleaning new-dies especially the expansion-ball , puts a lot-less-stress on things .

-

21-08-2023, 10:13 PM #39Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,008

-

22-08-2023, 08:37 AM #40Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,182

Greetings All,

I think the first thing to do in dealing with sizing problems is to understand what the problem is. Nine times out of ten a tight case is due to the case not having been sized enough. Rather than fumbling around in the dark purchasing a set of the Hornady comparators will quickly tell you if you have set the shoulder back far enough. These clamp onto the lower jaw of your callipers and measure from the case base to a datum point on the shoulder. The set is not expensive and no handloader should be without them. You should aim to set the shoulder back 0.05 to 0.1mm (0.002 to 0.004 ") from the position of the shoulder in cases fired in your rifle. If the cases still do not chamber with ease then you need to go looking for the tight spot, probably the case dia just ahead of the solid head. This is most common in rifles with little camming action and as mentioned above a small base die may be needed. I no longer use neck sizing dies other than for low pressure loads. There are better ways now. Decent quality sizing lube is important as well.

In short if factory ammo chambers with ease and our handloads do not then we need to lift our game. Grinding bits of our kit is not the answer.

Regards Grandpamac.

-

22-08-2023, 11:19 AM #41Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,008

Although with certain combos of dies and shellholders you can get into the situation of not enough resizing to do the job. The Redding style competition shellholders that step up in height in steps are really handy too, as is getting hold of a manual for your press (haha read the instructions) and if all else fails a small base die.

What I went to for resizing now, is a bushing full length die with competition shellholders starting at the longest length. Decap using a separate press and a decapping die, clean case, check for damage etc, into full length die with appropriate neck bushing, and check for length and chambering. All good from there, proceed to priming and loading. Anything that doesn't chamber gets a run with a shorter shellholder, bushing removed from the die to shoulder bump only then rechecked. If all good, that shellholder becomes the one I use going forwards...

-

22-08-2023, 12:40 PM #42

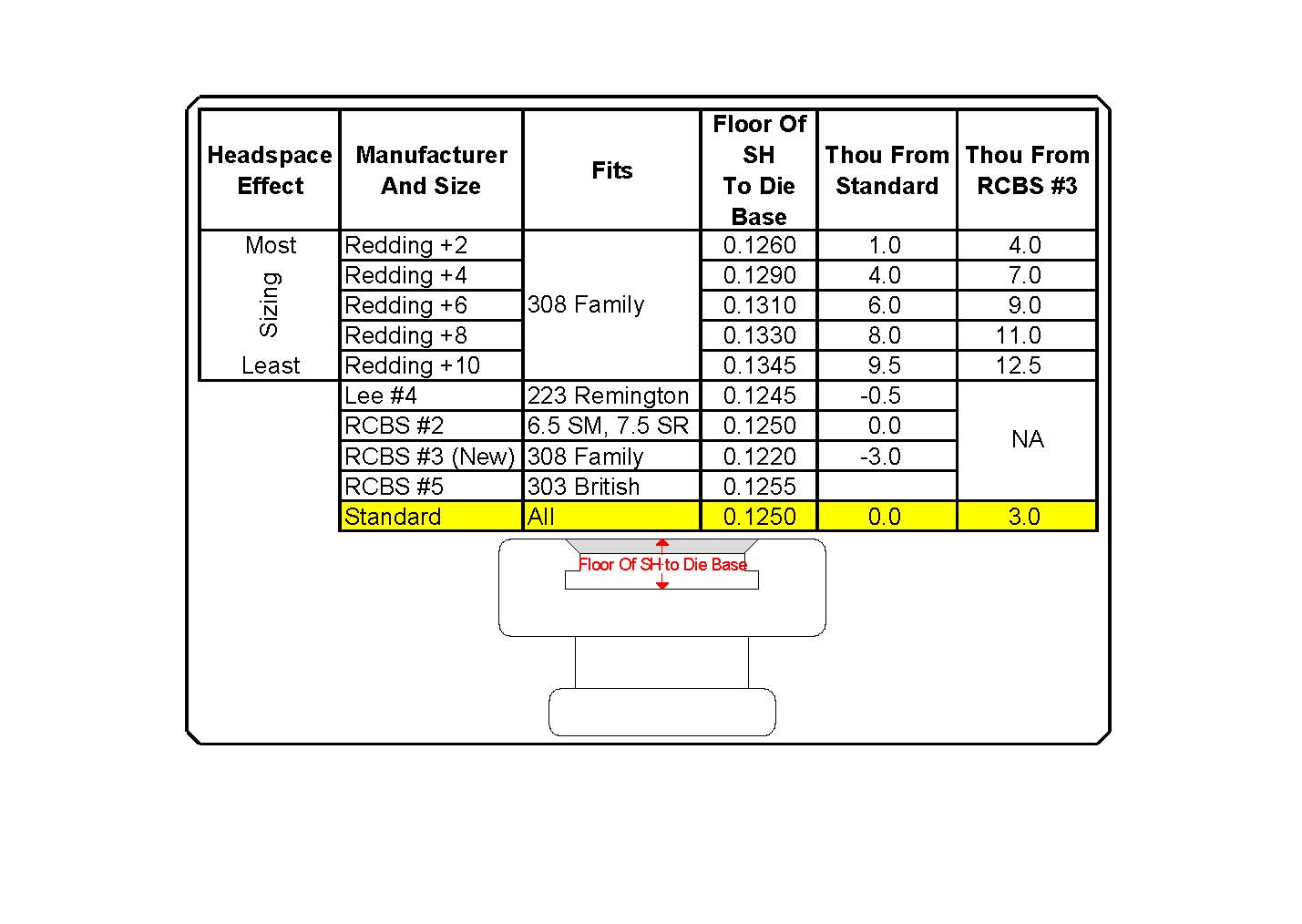

Ah, the mystic of shell holders.

It's not difficult to measure shell holders to determine variation from the industry standard of 0.125.

One example I have is 2 RCBS #3 shell holders. One very old, one newish. They both measure different so would give different results. The old #3 has been stored away.

I used to use the Redding Comp set for a while but as they only covered the 308 family, and I didn't wish to buy several sets I instead went to Skip Shims. They come in a set of about 8 IIRC so you can build combinations. They go on your die up against the die locking nut. Adjustments can be made in 1 thou steps.

I didn't like the Redding Comp in the end as I think their design should have the middle shell holder at 0.125 and the the others either side getting smaller and bigger.

I measured the Redding Comp ones at 3 points. They are also not true 2 thou steps, close though.

Mine are quite old so more recent ones may be better.

Last edited by zimmer; 22-08-2023 at 12:46 PM.

-

22-08-2023, 02:46 PM #43Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,182

Greetings @zimmer,

That got my attention so out to the shed. I measure in mm but with a little conversion back and forth two of my shell holders measure 0.125" and the other three measure 0.124". Interestingly only one of my rifles requires the standard shell holder, a Remington VSSF in .223 using a RCBS shell holder (0.124") and CH dies. All of the others that get full length sized need the plus shell holders. The plus 0.010" shell holder is is just enough in my T3 6.5x55.

Regards Grandpamac.

Similar Threads

-

T3 tight bolt lift

By andyanimal31 in forum Firearms, Optics and AccessoriesReplies: 7Last Post: 31-12-2021, 08:43 PM -

Closing the bolt...fire a cartridge?

By Hermitage in forum Firearms, Optics and AccessoriesReplies: 21Last Post: 26-07-2021, 08:42 AM -

Doc closing all their huts........

By Allgood in forum HuntingReplies: 13Last Post: 23-03-2020, 09:49 PM -

Newby reloading question. Tight bolt cases

By Curtis27 in forum Reloading and BallisticsReplies: 20Last Post: 29-07-2019, 07:27 PM -

tight bolt

By thejavelin in forum Firearms, Optics and AccessoriesReplies: 26Last Post: 10-09-2015, 12:33 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

100Likes

100Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks