Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 61 to 75 of 205

-

04-10-2020, 08:37 PM #61

-

-

04-10-2020, 08:38 PM #62

-

04-10-2020, 09:48 PM #63

-

06-10-2020, 07:05 AM #64

Ironically he's just swapped one "moving target" for another. Because what is 'jam'? One case with its own neck tension and runout will never leave the bullet in the exact location as any other case on earth.

Might as well use the 'just touch' method and take an average if you're looking to be super precise.

-

06-10-2020, 07:37 AM #65Member

- Join Date

- Jan 2018

- Location

- Christchurch

- Posts

- 725

No, that is incorrect. For the purposes of getting started with load testing, 'jam' is the point beyond which a projectile will stick in the rifling and stay behind if a loaded round is removed from the chamber. He never references this point after an initial measurement. It is a practical safety step to avoid a problematic situation.

The take away message of the video is not to try to measure where the lands are as this is futile (this is a moving target for sure). The whole point of the video is to show a methodology to let the target tell you what seating depth is best. By identifying the closest point to the rifling at which there is a 'tiny group node' to use as your initial length, you maximise your time shooting groups in that window.

After you've shot a bunch of rounds you load 5 rounds at the accurate length plus 3 thousandths to see if the window of accurate lengths has moved. There is no more measuring. Shoot a group to see if the lands have moved.

The only absolute is the base to ogive of a loaded round - this is easily measured.

-

06-10-2020, 01:10 PM #66

With the neck tension, bullets, and chamber leades where I've tried this, there has been 1mm of base-to-ogive difference in length between jammed and just touching. Backing off 20 thou (0.5mm) from jammed seems quite a large safety margin for range shooting, and would halve the available length settings I have to experiment with if wanting to keep the bullet in the lands. At the other end I also try to avoid getting too close to the just-touching position because I've found the pressure jumps throw the ES out, and accuracy also showed day-to-day inconsistency. So my preference is to keep the bullet engaged with the rifling and then my adjustment increments are from 0.2mm engaged through to 0.7mm engaged in 0.1mm steps, so 6 steps, hoping to shoot some smaller groups somewhere within those settings. As noted in the previous posts the reference point from where I take these measurements is arbitrary provided I know roughly where the two end points (jam and touch) lie, and can just be the CBTO gauge readings.

On a related but different topic, what are members using for their CBTO measurements please, and how sensitive to clamping force are the measurements if using vernier calipers, ie does the contact surface on the gauge have a tendency to bite into the bullet jacket?Last edited by Puffin; 06-10-2020 at 01:15 PM.

-

06-10-2020, 01:46 PM #67Banned

- Join Date

- Mar 2015

- Location

- North Canterbury

- Posts

- 5,462

Not having a micrometer seater myself, only verniers to measure, I have sometimes used a set of feeler gauges to accurately increase seating depth from my base measurement. Is this sensible or am I making a laughing stock of myself by even mentioning it ?

-

06-10-2020, 02:38 PM #68

Even with a micrometer die adjustment you still have to deal with the contact point of the seating stem being some way up the ogive from where the bullet will make contact with the rifling, and the possible variation in CBTO that that could introduce.

The Hornady gauge is inexpensive, and contacts closer to a more appropriate diameter on the bullet.

Anyone got a homemade gauge that they can post a photo of, with details on the construction, and of course of the huge improvements in accuracy that have accrued from its usage ?

-

06-10-2020, 02:53 PM #69Member

- Join Date

- May 2012

- Location

- Sydney

- Posts

- 1,806

RCBS make a calibre specific seating guage. Bos had a .270 win one for sale here recently. The hornady system above is more flexible if you shoot multiple calibres and you can thread your own cases for a custom chamber fit (and save a few dollars). Calibre specific collars are not expensive.

Moa there is a bit of variation in projectile length due to tip condition etc. So if you looking to make small adjustments it might not be so accurate working off total length. Working off the shoulder / contact point (ogive?) should be more accurate.

-

06-10-2020, 03:03 PM #70

-

06-10-2020, 03:24 PM #71

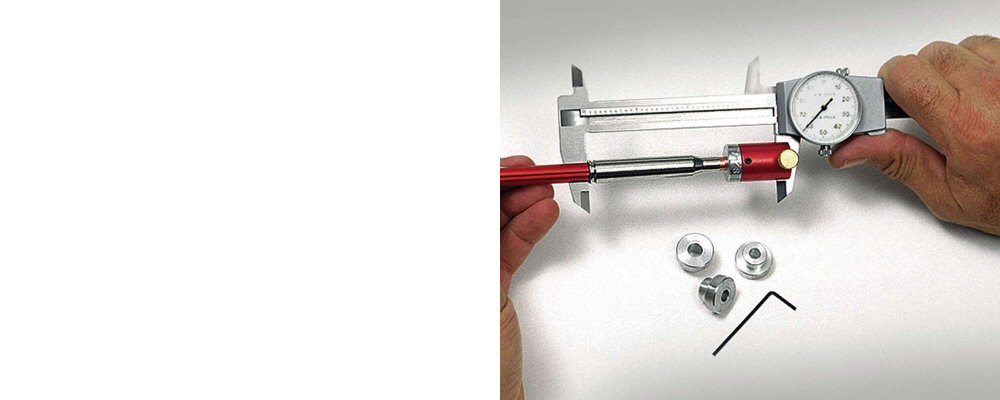

Just a note on the above, #69: threaded "modified" cases are for the OAL gauge, a measurement that M. Cortina is at pains to emphasize is not required for his method. The stock photo I posted is misleading. Please disregard the equipment on the left that appears to be the end of the OAL gauge and a modified case, and - at the risk of stating the obvious - the process instead being that each loaded (loose) round is measured with the bullet comparator, the part clamped to the caliper jaw on the right, and then returned to the seating die as required to get the CBTO all the same for a given number of rounds that will be shot as a group.

-

06-10-2020, 04:03 PM #72

For F Class, I, like most, batch my projectiles. Even with the better brands like Berger you can end up with 3 batches in a box of say 500. Hornady are the worst with some extreme outlyers. Although having said that my last lot of 7mm ELDMs weren't as bad as previous lots.

20 years ago Sierra used to be very bad box to box. It is the outcome of many projectile machines running in parallel with dies at various states of wear.

If you load into the lands you must check any newly acquired projectiles to avoid any surprises.

Some of the top Ozzies are also measuring the boat tails as well.

For hunting, not so important.

I have for years used the Stoney Point (now Hornady) ogive inserts. They do a reasonable job. I also have Sinclairs version of ogive inserts. They actually give a different reading to the Hornady ones. Either the Hornady or the Sinclair contact further up the "ogive", I can't remember which way round. IIRC the Sinclair gives a truer reading. For 30 cal I have a Redback ogive insert (Australian). It is the most accurate of all. It is made out of a section of rifled barrel (unfortunately not a section of my own barrel). It is cut with the same lead angle as my barrel.

-

06-10-2020, 04:29 PM #73

Interested to hear of this. I had discounted the option of using a chamber reamer for a home-made bullet comparator, my thinking being that the edge of the ring of contact on a gauge should be as sharp as possible - or at least, not of a shallow taper.

Understood that having a leade that matches the chamber has the advantage of contacting the bullet to give the true base-to-ogive distance.

My concern was that replicating the shallow leade angle in the gauge would make the measurement that much more subject to variation in the pressure applied by the caliper - forcing engagement to some extent with the gauge, and throwing the measurements about.

Any such issues ?

-

06-10-2020, 05:48 PM #74

Just a quick update, this is all on hold whilst I sort out a few things, I have sold my Lyman powder dispenser and will be replacing it with a RCBS chargemaster lite.

I have had a change of heart on projectile and powder choice also.

So will take me a few weeks to save some tokens and buy all the bits I need.

Basically I will start the process again and outline progress here.

I'm going to work up 150gn berger VLDH with ADI 2217 in my 270win

And Berger 168gn VLDH and ADI 2217 in my rem mag

All this in the hope of being able to use the one powder for both.

And just cause I'm a bit of a BC slut, I just like that the Berger pills are a lot more consistent

Will be selling off some 2225 and superformance in the hope of recouping some cost towards new stuff.

Will report back here when I'm ready to start again.#DANNYCENT

-

06-10-2020, 06:01 PM #75

Similar Threads

-

Load development in the SI

By Strider B in forum Reloading and BallisticsReplies: 21Last Post: 02-09-2020, 09:31 AM -

6.5 Creedmoor load development

By Wingman in forum Reloading and BallisticsReplies: 118Last Post: 29-09-2019, 10:38 PM -

300 Wsm Load development

By mcche171 in forum Reloading and BallisticsReplies: 10Last Post: 23-05-2019, 03:22 PM -

A novel approach to Load Development

By Puffin in forum Reloading and BallisticsReplies: 2Last Post: 16-08-2018, 11:36 AM -

Load development

By Cartman in forum Reloading and BallisticsReplies: 8Last Post: 30-07-2015, 10:42 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

304Likes

304Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks