Fellas

As you know I've always been a .243 kinda bloke. But the move towards higher BC, heavy and long for calibre bullets has got me interested in what else I can do with 6mm.

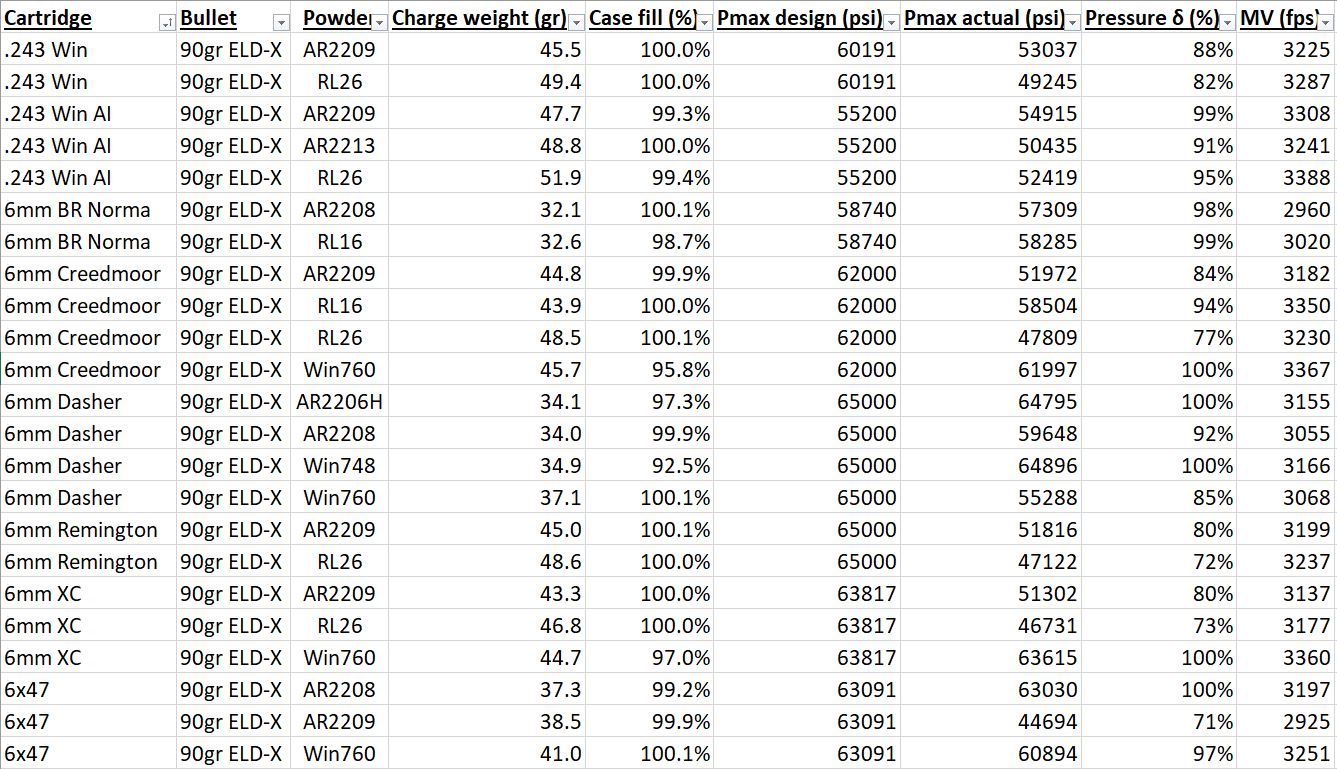

I ran through some of the options yesterday in Quickload, to see how they compared.

The assumptions I used was (a) the same bullet - 90gr ELD-X - so it would work in all rifles and not just fast twists, so 1:10" .243s are in the mix; (b) either a 100% case fill or maximum specified chamber pressure (Pmax), whichever occurred first. Obviously there's no accuracy component, what your rifle likes isn't quantifiable.

The results are really interesting. It shows that there's a couple of cartridges that are super efficient, with light powder charges for really decent velocity (6mm Dasher and 6 BR Norma), then the midfield is pretty much of a muchness, and as you'd expect the highest velocities belong to the highest charges (243 AI, 6mm Creedmoor and 6mm XC).

But what really stood out for me is the use of slower powders to get high velocity but low pressures. RL26 being the one I chose to look at... you can go on all day looking at dozens of powders. This is potentially a big positive for the throat erosion problem of fast 6mm rifles derived from the .308 parent case or similar.

However, we hear reports that not all rifles like RL26 and velocity and accuracy can be problematic. That said a good mate in the UK who I caught up with a couple of weeks ago (6mm Creedmoor) has nailed it using OBT and some very fine tuning of seating depth and is getting pretty much exactly what the model says he should.... plus one ragged hole. That's in a high end custom rifle however, but he's using it with great success in long range field sports - targets, hares, foxes and so on. He's a bit fussy about his deer shooting so no deer (yet).

Anyway, food for thought. I'll be adding to this spreadsheet and if anyone wants a copy that you can sort easily then flick me a PM.

By the way, those the say Quickload doesn't work.... I'd say 9 times out 10, once I get every single assumption 100% correct (particularly case capacity and consistent neck tension), my field outcome is pretty close to the model outcome. Batch-to-batch powder variability is a factor in differences of model vs actual, I've seen that with AR2209 when the only change to the velocity of 100 reloads is the powder batch number. But consistent neck tension is also a biggie (starting pressure).

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 31 to 40 of 40

Thread: 6mm cartridge comparison

Threaded View

-

09-08-2019, 11:06 AM #1

6mm cartridge comparison

Just...say...the...word

Similar Threads

-

Deer size comparison....

By Scouser in forum HuntingReplies: 36Last Post: 07-05-2024, 07:53 PM -

AR comparison

By jakewire in forum Firearms, Optics and AccessoriesReplies: 7Last Post: 29-01-2018, 05:41 PM -

Scope comparison

By BRADS in forum Firearms, Optics and AccessoriesReplies: 56Last Post: 23-09-2014, 09:41 PM -

4WD Shock Comparison

By cambo in forum Outdoor TransportReplies: 16Last Post: 10-01-2014, 06:32 PM -

Brake comparison on a 300 RUM

By Kiwi Greg in forum Terminator ProductsReplies: 14Last Post: 28-04-2013, 06:59 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

29Likes

29Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks