Shit..

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 46 to 60 of 60

Thread: Airgun Interest

Hybrid View

-

09-10-2021, 05:17 PM #1gun guyGuest

-

09-10-2021, 05:16 PM #2gun guyGuest

Airforce talon 22 BSA magnum I think its called and h&n barracuda vs 44gal drum at 30m fired from talon

-

30-12-2021, 10:03 PM #3Member

- Join Date

- Mar 2012

- Location

- Waikato

- Posts

- 2,188

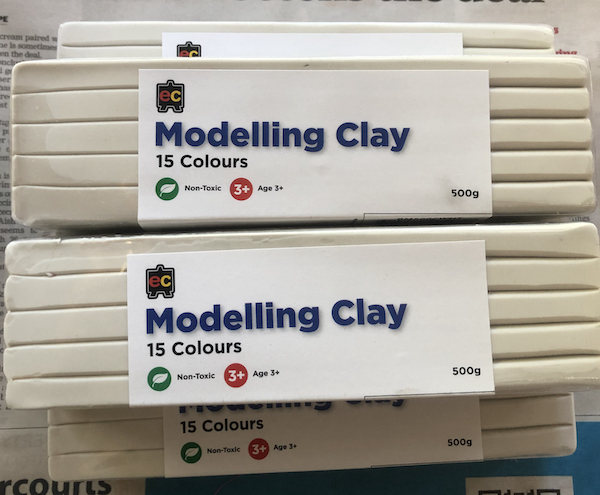

Test Fire: Modelling Clay for an Airgun Pellet Trap

Method

I used a break barrel, spring powered Weihrauch HW95 in 22 cal. Pellets were H&N Field Target Trophy 14.66 gr at MV 680 f/s, giving 16 ft.lb at the muzzle and 14 ft.lb at the test range of 10m.

The modelling clay was from Educational Colours Pty Ltd, Victoria AU. It is available from a variety of online retailers at $5 to $7 per 500g block. Ingredients are not disclosed but it is claimed to be non-toxic, non-drying and melts at about 70C, so itís likely an oil based ďplasticineĒ type material. It was tested as supplied and also mixed 3 parts by weight plasticine to 1 part dry red sand (washed) from the subsoil in my back yard.

Preliminary tests were done with planned backing materials: old dry 20mm dressed pine wood and a plastic chopping board (retired).

The clay blocks were initially trialled at 40mm thick for single shots, then reshaped to 60mm thick for 5 shot groups.

Paper targets were mounted on plastic corflute in contact with the block of clay and behind that were the plastic board and a sandbag. I used eye protection.

Result

Penetration in pine: 6mm to base of pellet. The pellet embedded in the wood.

Penetration in plastic: 1mm crater. The pellet dropped off.

Penetration in 40mm plain clay block:

One shot >42mm (right through)

Penetration in 40mm clay:sand 3:1 block:

One shot 37mm

Penetration in 60mm pure clay block:

5 shots >60mm (right through)

Penetration in 60mm clay:sand 3:1 block:

5 Shots 45mm

Illustrations

01 EC brand white modelling clay

02 Cut clay used for 3:1 sand block

03 125 g red sand

04 Pine block

05 Plastic chopping board

06 One shot into pure clay showing the chamber flag used to measure the penetration depth

07 The back of the 40mm clay block showing full depth penetration

08 Pellet from 40mm clay showing the dome flattened by hitting the plastic back board

Corflute and clay have been wiped off, leaving the red target paper embedded.

09 60mm pure clay block test setup

10 Back of pure clay block after 5 shots

11 Pellet marks on plastic board through 60mm of pure clay

11A 5 pellets recovered from the 60mm pure clay block

12 Clay:sand 3:1 block. One shot at 10m.

13 Back of the 40mm clay:sand block showing the pellet didnít go right through.

14 Pellet recovered from clay:sand block showing abrasion of the head

15 Clay:sand thick block setup

16 Clay sand block 5 shot group front of block showing some crumbling

17 Clay:sand block showing penetration depth

5 shot at 10m range. 45mm penetration

Conclusions

Thick clay, perhaps 100mm, is needed to stop heavy pellets like these, specially in a close group on the same target.

Wood captures pellets well.

Plastic stops pellets well but could be prone to ricochet.

It is quite hard to work the sand/clay mix by hand and it would be difficult to press back into shape without leaving voids or crumbly spaces.

-

30-12-2021, 11:22 PM #4Member

- Join Date

- Aug 2017

- Location

- King Country

- Posts

- 2,465

And there I was, in the 60's wondering just how far my Gecado 23 would shoot if I pointed it up in the air...

-

05-01-2022, 11:01 PM #5Member

- Join Date

- Nov 2020

- Location

- Auckland

- Posts

- 656

If you're wondering what potential your airgun has, use jsb

medium weight for .177 and RWS barracudas for .22.

Yet to see any airgun that hates those.

I used to practice shooting tiny groups everyday with my AA200HC springer. Wouldnt be happy unless it 5shot cloverleafed at 40y at least once a session (sitting off the knee in std FT position).

Last edited by T.FOYE; 05-01-2022 at 11:12 PM.

-

06-01-2022, 08:01 AM #6Member

- Join Date

- Feb 2014

- Location

- Hawkes Bay

- Posts

- 2,708

One idea for a backstop is to make a small box with two or three layers of Coreflute lining the front face. Coreflute is partly self-healing when projectiles go through. You'd fill the box with sand or similar which would prevent any voids for pellets to get through, something that clay clearly isn't good at. I haven't tried it but I'd guess 50mm of sand would stop any pellets, even from a PCP.

-

09-01-2022, 04:42 PM #7

-

09-01-2022, 07:30 PM #8Member

- Join Date

- Sep 2017

- Location

- Wellington

- Posts

- 1,817

-

10-08-2022, 10:49 PM #9Member

- Join Date

- Mar 2012

- Location

- Waikato

- Posts

- 2,188

Light pellets in a spring airgun ?

It's said that if its too light, the spring / piston slams down too fast and things will break.

What is "too light" supposed to be for a 177 or a 22 cal ?

-

22-08-2022, 03:56 PM #10Member

- Join Date

- Mar 2012

- Location

- Waikato

- Posts

- 2,188

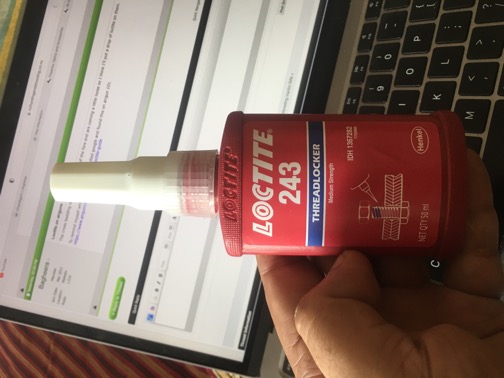

Loctite on airguns

The cross bedding screws at the far end of the fore end are coming a little loose so I think Iíll put a drop of loctite on them.

To remind myself which one to use I consulted google and found this on airgun 101.

https://www.airgun101.com/fx-airguns...-loctite-guide

-

23-08-2022, 03:59 PM #11

I have been using this without any issue on all my airguns since last few years. It is supposed to be medium strength but I haven't got any chance to open the screws

-

27-10-2022, 09:00 AM #12Member

- Join Date

- Jul 2022

- Location

- Hawks bay at moment

- Posts

- 628

I use the the full strength loctite.

I only use it on the end few threads, if I can see the end of screw where it threads in I'll screw it in till just about all way in then put a small drop on let sit for a few secs and then finish screwing in. I haven't had an issue when it comes to undoing them. I wouldn't coat the whole thread.

A gun tuner actually recommended nail polish. Which makes sence too. Haven't tried that yet.

-

23-08-2022, 07:38 PM #13Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,184

Ive got an older gamo model -trigger unit has a buggered spring so i took it apart .someone told me of a guy out kaiapoi canterbury way who dealt in these things -anyone know the details .some attention to the piston /airchambewr might also be required .can thse be honed??

-

31-10-2022, 05:14 PM #14Member

- Join Date

- Jul 2022

- Location

- Hawks bay at moment

- Posts

- 628

try Vaughans in Upper hut for parts. He's the gamo importer and may have the part equivalent or even an old rifle to get parts off.

whats the bore damage that it needs honing?

If your just giving it a dam good clean jb non embeding bore paste seems to be a well recommended product.

You can probly get a replacement barrel if you wanted. Again try vaughans.

-

27-10-2022, 01:46 PM #15

I have a diana model 25 is great condition for sale..... woodwork is 10/10,metal work is 9.5/10 there is one of the main screws been replaced and the rear sight is missing,its a model that was drilled n tapped for scope mounts,it even says that on action...

its in the for sale section if any interest ,feel free to tell me if Im miles off with price,was not sure at all what it was worth...collectable maybe.useable definately.75/15/10 black powder matters

Similar Threads

-

How to verify an airgun is unloaded ?

By Bagheera in forum Firearm SafetyReplies: 12Last Post: 28-10-2015, 07:08 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

60Likes

60Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks