Brettra nz bring in tikka/sako

Is the barrel free floated properly if theres a contact point where there shouldn’t be it will bugger accuracy

Sounds silly but is everything tight scope rings installed correctly etc

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 51

-

25-09-2018, 12:09 AM #16Member

- Join Date

- Aug 2012

- Location

- helensville nz

- Posts

- 4,742

-

-

25-09-2018, 12:11 AM #17

If all else fails, take it to a highly recommended gunsmith. A friend of mine had a Parker Hale 308 that he just could not adjust windage on sufficiently.

He took it to Nelson Collie in Invercargill who spotted a problem with the mounts that had escaped everybody else.

A really good gunsmith may be able to diagnose something has gotten by all other attempt to fix it.

I have no idea who to recommend in your area.

-

25-09-2018, 01:28 AM #18Member

- Join Date

- Jun 2013

- Location

- Middle Earth

- Posts

- 4,574

As mentioned above checking that recoil lug is well engaged. The bottom of the gas port on the left side of the action should be level with the top side of the stock.

A mistake often done by many ( included myself in the past)when taking the tikka out of the original plastic stock and putting it back is the over torquing of the action screws. Despite the manual stating quite a high torque ( around 50 or 60 inch pounds on top of my head) the screws are definitely not torqued as high from the factory.

Probably more around 25 inch pounds. When the action screws are over torqued , the shape of the bedding into the stock is modified and the support is not the same anymore and that can affect how well the rifle shoots.

One Remedy is to cut some coke can aluminium foil and place them between the stock bed and action in a way that can be located evenly under the "round" part of the action either side of the action screw location.one layer is usually enough. This helps to rise the action from the previously crushed area and can help restore accuracy .

That solution is only a quick fix for the synthetic stock issues and to test the rifle and determine if a proper bedding is required or not.

I fixed my second hand 270 wsm like that.

A bedded wooden stock or any good aftermarket stock should not have those issues and action screws can be torqued at a higher poundage.

The barrel could be stuffed.

We have a tikka in 223 at work that is not a great shooter with most ammos except the outback 69 grains sierras.

I also once worked on a tikka 223 barrel that had its chamber with 0.15 mm of run out to the axis of the bore. I cut the chamber out and rethreaded and rechambered the barrel in fresh rifling with less than 0.01 of runout of the chamber. That did help it to shoot better.

-

25-09-2018, 02:33 AM #19

Have you tried removing and checking the rings and bases, they can be a common cause of problems.

You will know when the action is in the recoil lug correctly as the action usually snaps into place, can take a bit of pressure sometimes. The vent hole in the side of the action should only just be visible above the top edge of the stock.

-

25-09-2018, 08:00 AM #20Member

- Join Date

- Jul 2013

- Location

- Waikato

- Posts

- 2,620

Try running a cotton bud lightly around the inside of the muzzle of the barrel,will catch on even the tiniest burr which might not be visible to the naked eye.

-

25-09-2018, 08:02 AM #21Member

- Join Date

- Feb 2014

- Location

- Hawkes Bay

- Posts

- 2,727

The first thing I would do is give it to someone with serious cleaning gear and let them have a real go including JBs. If you know anyone with a borescope, get them to have a close look.

Unless you've --definitively-- ruled out fouling, you could be wasting time and effort chasing other ghosts.

-

25-09-2018, 08:42 AM #22

What Friwi said about the action screw torque. What have you been tightening the screws to? Just “tight” as in when the screws stop and a little bit more, or “proper tight” as is when the screws turn with slight crack noise? Did you use a torque wrench.

I have a few Tikkas and they all shoot brilliantly, except the one (308) after I overtightened the actions screws on and compressed the laminate stock. I was able to isolate the cause of accuracy loss quickly, because you can see the compression. When I say overtightened, I followed the instructions and used a torque wrench. Never really understood why the numbers are as high as they are, in the instructions, for soft stock materials. Anyway I fixed it by steel pillar bedding the stock and lifting the action ever so slightly, first with the coke can method, then by thin bedding compound. Problem solved, normal service resumed.

-

25-09-2018, 09:46 AM #23My favorite sentences i like to hear are - I suppose so. and Send It!

-

25-09-2018, 10:46 AM #24

+1 for don't over tighten the action screws. 25 -30lbs torque max. If you over tighten you will compress the plastic stock and it wont recover. If you can get hold of another tikka stock from someone else try swapping that over to your action/barrel and torque actions screws carefully and < 30lbs.

If it shoots well you have your answer.

-

25-09-2018, 11:00 AM #25Member

- Join Date

- Jul 2012

- Location

- Napier, Hawkes Bay

- Posts

- 4,460

I would hazard a guess that many rifles get sold on as the accuracy starts to drop off, they try everything they can think of to look for the problem, then give up and sell it on. Very likely carbon fouling would be the problem.

I have a 7mm08 that shot awesome, then eventually maybe after 200 to 300 rounds from new it started grouping at 3-4" at 100 yards, checked everything to no avail. Finally someone suggested that my normal cleaning process may not have been removing the carbon, i scrubbed the bore with a Autosol on a patch, and what do you know, back to 3 shots touching.

Ive changed my cleaning process now.

-

25-09-2018, 11:42 AM #26Member

- Join Date

- Jan 2018

- Location

- New Zealand

- Posts

- 796

Personally I despise that "sniper 101" guy for creating the "copper equilibrium" fad of never cleaning your rifle. Rifles get returned that do not meet accuracy guarantee because they are caked full of crap...because "copper equilibrium"

Cleaning regime I would use in such situations.

Apply wipe out to barrel - let it sit for a couple of hours.

Run a bore brush back and fourth down the barrel 10 times.

Patch Out.

Repeat over a day or two. Perhaps 5-10 cycles depending on how fouled it is.

Firstly give the barrel a serious clean as specified above.

Then, as others have said - make sure the action is sitting in the lug correctly. Take action out of stock and put it back in. Maybe even post a picture of the gap at the front of the barrel as we may be able to tell you if looks to be seated correctly based off the gap.

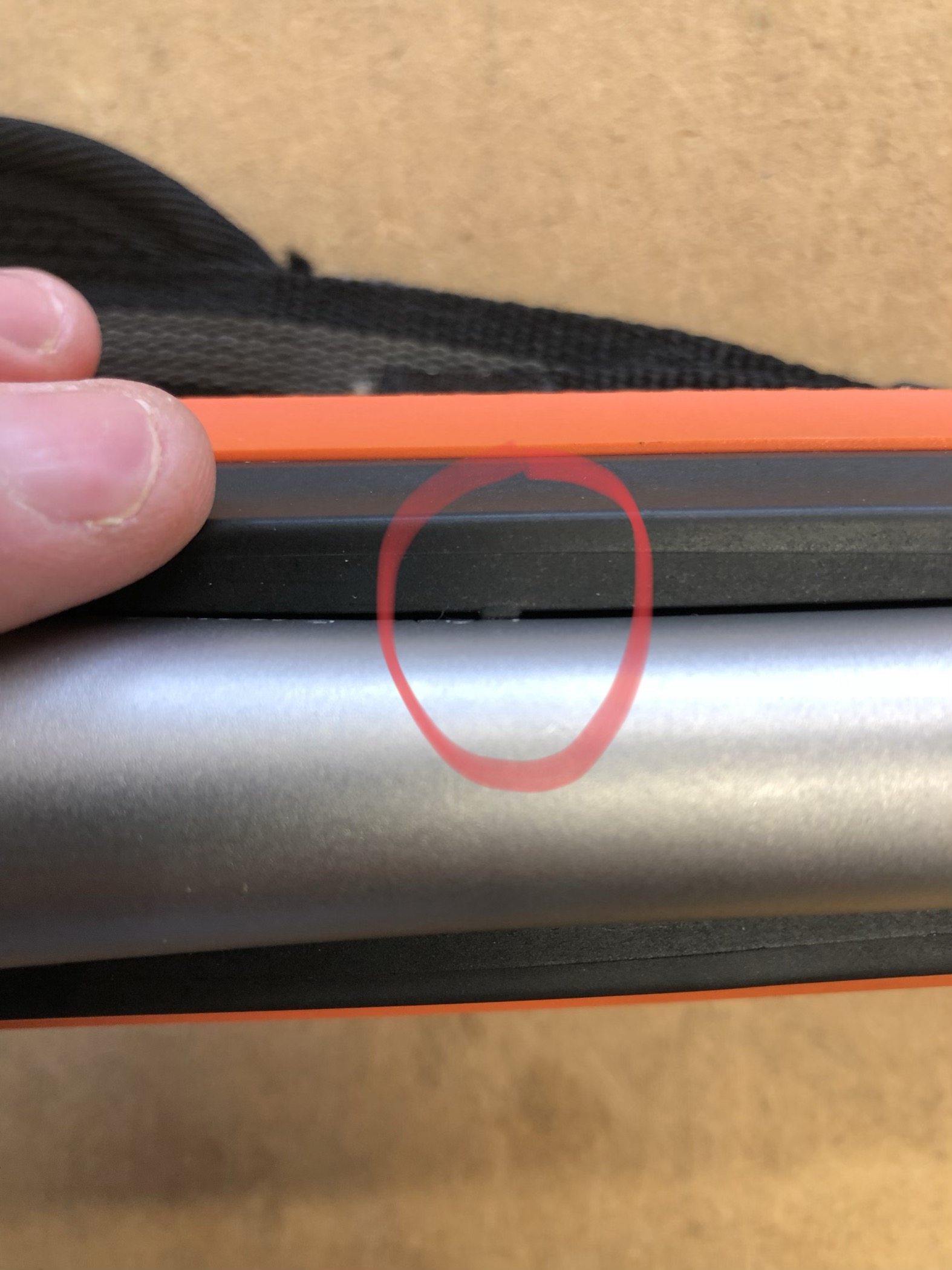

I understand you have already done it - but for anyone else..Do not remove the pressure points in the stock. There are two purposeful contact points a couple of inches in front of the action. They are meant to be there. Do not remove these as it may well void any accuracy guarantee and make the rifle inconsistent. It should be free floated to about 2" in front of the action to where the pressure/support points are. See image.

-

25-09-2018, 12:49 PM #27Member

- Join Date

- Jul 2012

- Location

- Napier, Hawkes Bay

- Posts

- 4,460

-

25-09-2018, 01:08 PM #28Member

- Join Date

- Feb 2017

- Location

- Jafa land

- Posts

- 5,535

-

25-09-2018, 01:14 PM #29

-

25-09-2018, 01:18 PM #30Member

- Join Date

- Jan 2018

- Location

- New Zealand

- Posts

- 796

Similar Threads

-

Pukeko and "Sensitive bird caring frustrated gardener" problem.

By LBD in forum Game Bird HuntingReplies: 48Last Post: 12-05-2017, 10:44 AM -

Shooting Apps "Range Buddy" and "Reloading Assistant"

By Dead is better in forum Resource LibraryReplies: 4Last Post: 14-01-2017, 05:23 PM -

Evolve LED Light Bar For Offroading in sizes 18",20",28",36",43"

By pighuntingnz in forum Outdoor TransportReplies: 4Last Post: 27-12-2016, 08:05 AM -

"sausage making course" and "curing & smoking course"

By hotbarrels in forum Game Cooking and RecipesReplies: 3Last Post: 06-08-2016, 09:11 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

53Likes

53Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks