WTF? Thread shouldn't end because you say so. And if you are supplying a product for hard earned money you betcha it better be correct/perfect and backed up within reason or you wont be in business long.

The supplied rifle had a fault that imo, is neither the suppliers or consumers fault but the supplier has the expectation and responsibility to first recognize it (seems he did) then rectify or replace it at no cost to the consumer. Simple really.

Shit happens. We all know that. An apology if needed and payment for repairs would not only save face, it will close the thread.

Sent from my SM-T510 using Tapatalk

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 61 to 75 of 81

-

10-07-2020, 02:00 PM #61Do what ya want! Ya will anyway.

-

-

10-07-2020, 02:12 PM #62northdudeGuest

Careful someone will get offended we dont want that now do we

-

10-07-2020, 03:24 PM #63Member

- Join Date

- Mar 2014

- Location

- Tauranga

- Posts

- 3,033

Its 2020 mate, you need to consider all communities before choosing your rifle calibre. One must be careful not to offend. Also 7mm08's arent trendy anymore so whats a they who likes a fancy coffee, living in an overpriced house and changing gender every wednesday to do?

-

10-07-2020, 06:27 PM #64northdudeGuest

Buy a creedmore

-

10-07-2020, 06:40 PM #65

If youre buying a ute as a work vehicle and you tell the dealer what you want and he says yea yea this will be perfect for you. Then you tell him ok I will lease it for a year first and then purchase it IF it does what you have just told me it will do. Watch them swallow their words

Flappy Disc Customs Bespoke Hunting Rifles

-

10-07-2020, 07:32 PM #66

Mikee you were extremely happy with the rifle when it was returned to you last time.

The welding my subcontractor put on the bolt was done with the "heat turned up" this is why it looks as it does when the shroud is removed

He did this to ensure the handle stayed in place as it had been hit multiple times to open the bolt after brass had become stuck in the chamber

We know now that Remington's can have significant primary extraction issues, that was not the case when this rifle was built nearly six years ago now.

It is difficult to find anyone in this country who can re-time Remington bolts to maximise their primary extraction with the factory bolt handle

In this case the primary extraction was correct with the factory bolt handle & not the cause of the cases failing to extract

Your email said "when I tapped the bolt to free it the extractor let go of the case"

If a case is stuck in the rifle hard enough for the extractor to let go of the case by either camming over it or tearing the rim off no amount of primary extraction is going to remove it from the chamber

There are many reasons for a fired case to become stuck in a chamber

Before I sent the rifle away to have the handle tig welded on I tightened the screws up the previous contractor had put in the handle to try to keep in on as the factory solder would not hold.

After I cleaned & polished the chamber the bolt would happily extract the dirty fired brass supplied with the rifle from the chamber

The factory bolt handle cannot cope with the primary extraction being consistently used to free the case from the chamber, the metal is too soft & it doesn’t have enough area or angle to accomplish that especially with a case design like the SAUM

It is unfortunate that I have never had an opportunity to preform a function test of the rifle by firing it since I sold it.

This situation would have been easily resolved by an email that went something like,

Hey Greg that rifle isn't working again for some reason, it was going great but now its not can you please have a look at it again for me.

As opposed to the ones I received

I had never before been threatened with the C.G.A. in over 25 years of running a business

"You can't please all the people all the time" & "The customer is always right"

Hopefully the rifle continues to function as it should as it has always shot extremely wellContact me for reloading components, brass, projectiles, powder, primers, etc

http://terminatorproducts.co.nz/

http://www.youtube.com/user/Terminat...?feature=guide

-

10-07-2020, 07:57 PM #67

thankyou Greg...that puts a different spin on things.....completely.

-

10-07-2020, 08:44 PM #68

So then why was my bolt needed to be replaced

As I said before why the hell is it so hard to get you to answer to anything,

If you truely believe that there is nothing wrong with the rifle why did you not agree to meeting me so I could show you why I believed the issue?

And why did I still have issues ?? What your guy did was screw the handle on and tig it on over the top.

Apart from December this year the handle was never hit with anything.

There is nothing wrong with brass like that.

You have blamed the action, my cleaning, my reloading,

More deflections and excuses, Is repair work like that really acceptable on a 5K gun?

I have said my piece, I am sure I was not the first guy you ripped off and wont be the last!

-

10-07-2020, 08:44 PM #69

.

Quis custodiet ipsos custodes?

-

04-06-2021, 09:08 PM #70

do you want another rem 700 bolt...one from 7mm mag just popped up ....same size????

-

04-06-2021, 09:21 PM #71

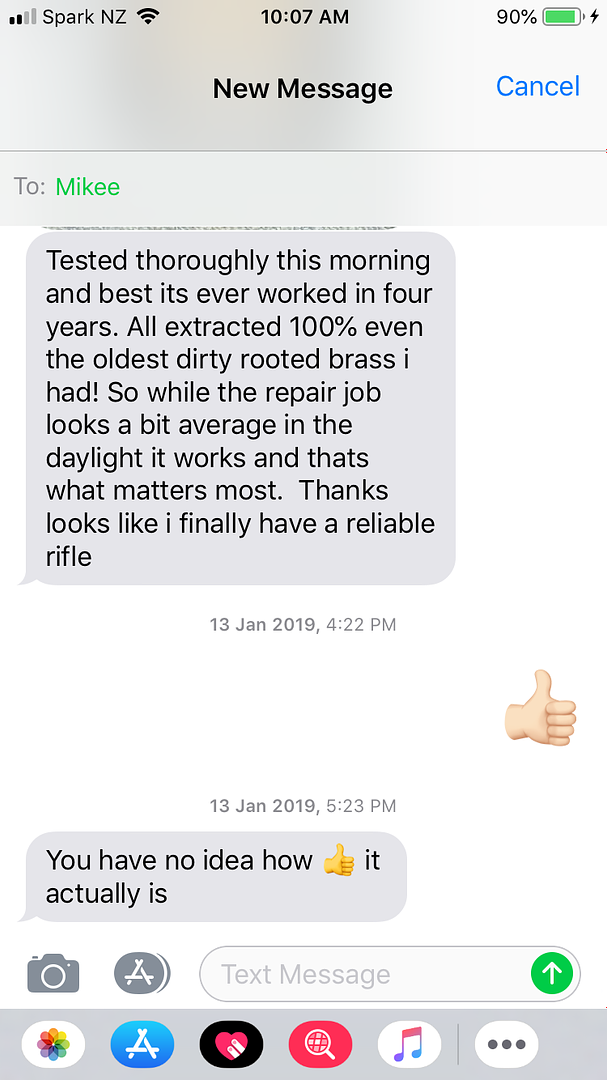

Nah needed a short action one. In any case I brought a proper brand new bolt (PTG) and had it fitted by a proper gunsmith. Fired 700+ since and not one single failure to extract, not one!

Sooooooooooo I guess is really was me and my sloppy reloading of dirty brass rather than the shoddy work done and redone originally.

Now that its not a battle to use the thing it gets used.................most every weekend

-

04-06-2021, 09:22 PM #72

took a lot of digging to find thread LOL...good you sorted finaly.

-

04-06-2021, 09:30 PM #73

Similar Threads

-

6.5SAUM or 6.5WSM

By 25/08IMP in forum Reloading and BallisticsReplies: 18Last Post: 11-04-2016, 11:45 PM -

Terminator Products You Tube Link.

By Kiwi Greg in forum Terminator ProductsReplies: 5Last Post: 17-04-2013, 08:40 AM -

Terminator Products calibres

By Kiwi Greg in forum Terminator ProductsReplies: 6Last Post: 07-07-2012, 02:19 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

130Likes

130Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks