Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 106 to 120 of 130

-

11-01-2017, 05:49 PM #106Member

- Join Date

- Jan 2013

- Location

- Auckland

- Posts

- 590

-

-

23-01-2017, 12:43 PM #107Member

- Join Date

- Feb 2016

- Location

- Stewart island / canterbury

- Posts

- 9,193

Any tips and tricks to loosen up the mag in the mag well? Since mines got the screw at rear of receiver fitting into the stock the mags don't want to drop out under gravity and need to be yanked out or shaken. Any it's or is it just a good excuse to go from the standard 10round to a 15 so there's something to grab to pull it out and a bit more weight

-

26-01-2017, 08:32 AM #108Member

- Join Date

- Feb 2016

- Location

- Stewart island / canterbury

- Posts

- 9,193

Also discovered my safety is a bitch to flick off, push partway push back to safe then push all he way to fire. Is it possible that it has rotated somehow? Anyone tried putting a left-handed safety in? If I'm going to take it to bits I might chuck a more appropriate part back in

-

26-01-2017, 09:28 AM #109Member

- Join Date

- Aug 2015

- Location

- Auckland

- Posts

- 50

where do you get the flush magazine releases from? My partner and myself have lost a magazine each

-

26-01-2017, 09:32 AM #110Member

- Join Date

- Feb 2016

- Location

- Stewart island / canterbury

- Posts

- 9,193

-

26-01-2017, 12:54 PM #111Member

- Join Date

- Mar 2016

- Location

- Arrowtown

- Posts

- 1,349

-

26-01-2017, 01:02 PM #112Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,335

Just cut the extension tongue off the latest factory catches, pretty it up with a file and sandpaper, and you have a flush mag release. End of problem! Tight magazines need dressing a little on the 4 vertical corners. A 1mm 45 degree chamfer cut with a sharp chisel will do the trick.

-

26-01-2017, 04:20 PM #113Member

- Join Date

- Feb 2016

- Location

- Stewart island / canterbury

- Posts

- 9,193

-

31-01-2017, 12:37 PM #114Member

- Join Date

- Mar 2016

- Location

- Arrowtown

- Posts

- 1,349

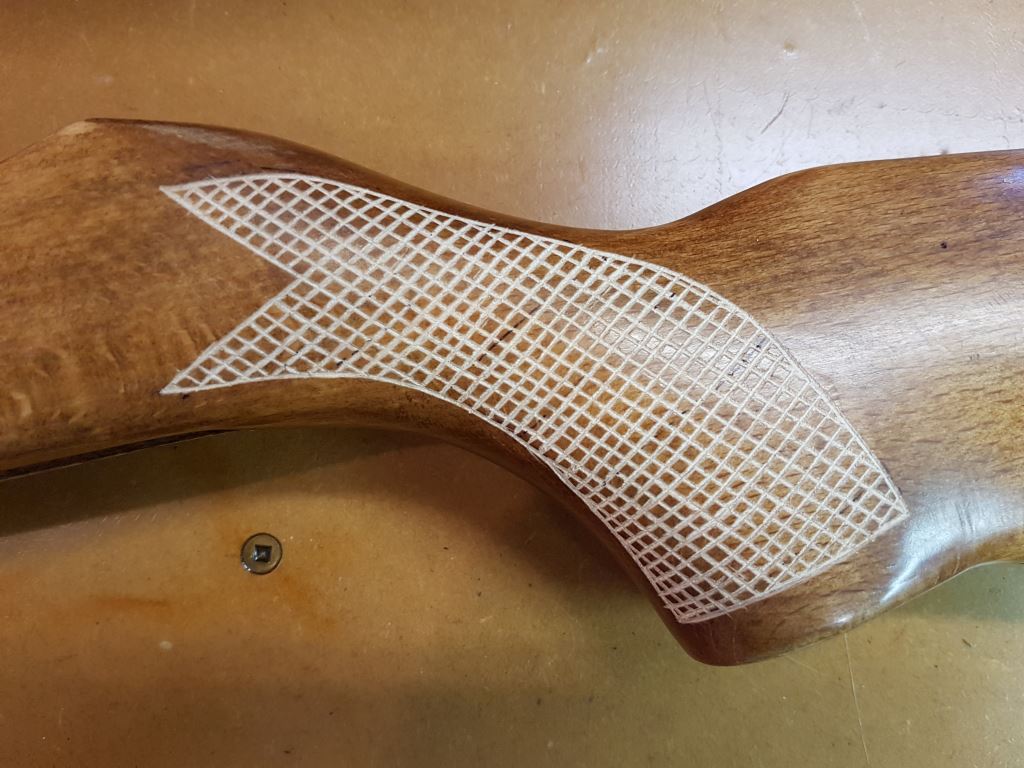

Stock modification

My daughter Mikayla (12) was doing ok with the standard rifle but I noted the difficulty she was having with the standing shots.

Her smaller frame meant it was difficult to shoulder the rifle correctly so a change was needed. I purchased an old beat-up wooden stock off TM for SFA and set about making some changes. I don't like the standard stocks much at all so anything was going to look better than what I had.

First I trimmed about 2" off the back. By chance this worked out to be about perfect. I cleaned up the butt and using my best wood-working skills plus some cursing and swearing, got the plastic protection to fit.

Next I trimmed a bit of meat off the fore end of the stock. The primary reason for doing this was to make it easier for smaller hands to hold on to. I based the shape on a Winchester M70 Featherweight I have. Mikki indicated this change was an excellent one and she can now hold the fore end much easier. I guess it might have reduced the weight a bit too, although bugger all. I drilled a bit of meat out of the butt of the stock too. While I was there I made sure the barrel was floating correctly in the channel too.

After a bit of sanding, some good ol' fashion elbow grease, a few coats of Birchwood Casey Stock Varnish, more elbow grease and finally some TLC, the finished article was handed over for field trials. It was an instant hit - no pun intended. Funny enough, Mikayla now refers to this as "her gun". Hmmmm.

Without checkering on the stock I thought the rifle was looking a little... bland. I wanted to tart it up but I don't even know how to use a chisel, let alone own one. I mulled over the options but left it alone for a few months. When my son was given a craft set for Christmas I noted the small "V" chisel inside the box and the brain started churning out ideas. With no skills and very little appreciation for the time and effort involved I set to. I now believe those guys in European factories who do this as a day job need to be paid more.

The final result was rough enough for the money I got paid and Mikki is rapt with the new addition.

Next stop - the local Marae. Maybe I can whip up a bit of carving for the Wharenui.

-

31-01-2017, 01:45 PM #115

Being the cheap bugger I am, I used to fashion the V carving tools out of umbrella ribs, and tickle them up on the bench grinder.

There are only three types of people in this world. Those that can count, and those that can't!

-

31-01-2017, 01:50 PM #116Member

- Join Date

- Jun 2015

- Location

- christchurch

- Posts

- 18,511

the number one improvement is a good trigger job, then a plastic buffer pin. then get rid of that dovetail base and put a weaver base and rings on

-

31-01-2017, 09:14 PM #117Member

- Join Date

- Mar 2016

- Location

- Arrowtown

- Posts

- 1,349

-

01-02-2017, 05:37 AM #118Member

- Join Date

- Nov 2014

- Location

- Christchuch New Zealand

- Posts

- 6,248

-

07-02-2017, 06:02 PM #119

-

02-03-2020, 10:55 PM #120Member

- Join Date

- Jul 2013

- Location

- Waikato

- Posts

- 2,574

Reviving an old post as I have just got a 10/22 and looking for any tips on accurizing it.

Similar Threads

-

Tips and tricks on new bike.

By anderset20 in forum Outdoor TransportReplies: 21Last Post: 11-10-2015, 08:32 PM -

Bush hunting tips and tricks

By jhunt in forum HuntingReplies: 24Last Post: 09-08-2015, 10:57 PM -

Tips/tricks/advice/recipes/whatever

By Angus_A in forum Game Cooking and RecipesReplies: 78Last Post: 09-01-2015, 10:15 PM -

Scope mounting tips and tricks

By Gibo in forum Firearms, Optics and AccessoriesReplies: 45Last Post: 23-10-2014, 09:24 PM -

Rabbit hunting - tips and tricks and the push-gutting method

By Kumoe in forum Varminting and Small Game HuntingReplies: 20Last Post: 20-03-2014, 08:09 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

101Likes

101Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks