Further to the discussion above, here's one of the research notes.I saved...

"Use 0000 steel wool DRY.

The removed rust is an abrasive, if you put oil on the metal surface or on the steel wool, the removed rust is retained and rubbed on the surface which can damage the finish.

If you use the steel wool DRY, shake it out frequently and keep the surface of the gun dusted off the removed rust doesn't get rubbed around on the finish. Keeping the steel wool free of rust particle will minimize damage to the remaining finish.

You can oil the metal surfaces AFTER the rust has been removed but you want them to be as dry as possible while you're actually using the steel wool.

I'm posting this because I see a lot of people recommending the use of oil and steel wool to remove rust and I know from experience that is much harder on the finish. I used to have a friend with a gun shop and I would go over all the used guns each week to keep them oiled and rust free. Since they were out in the customer area, not behind the counter, they had been handled and some would build up light surface rust. I would oil them if they weren't rusty and remove the surface rust if they were rusted. It was easy to see the difference between using the steel wool with oil and without."

So yes, there lots of recommendations out there to use oil with the steel wool. Using it dry is counterintuitive..but there are good reasons to do so. But go do your own research, don't take my word for it.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 40 of 40

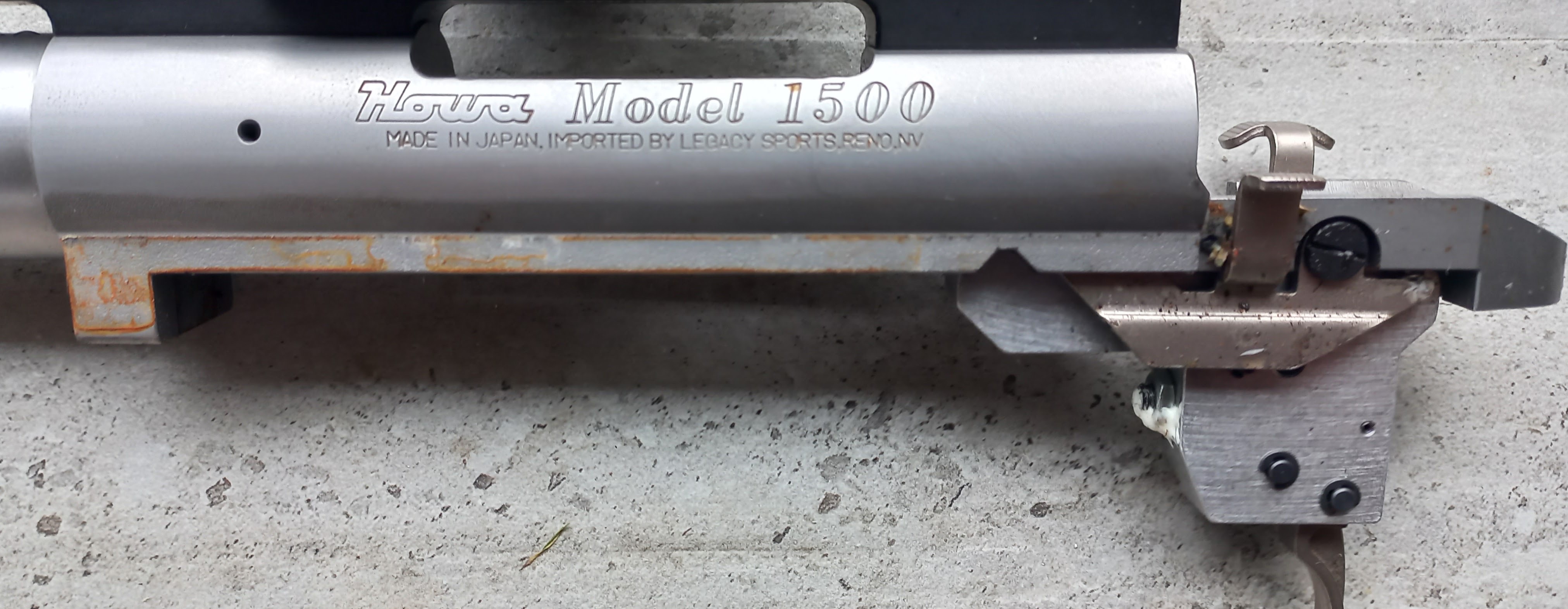

Thread: Rusting Howa's

Hybrid View

-

30-06-2021, 04:49 PM #1Member

- Join Date

- Apr 2017

- Location

- The 'Naki

- Posts

- 2,623

-

30-06-2021, 08:36 PM #2

We can probably empirically test this.

-

01-07-2021, 05:11 PM #3Member

- Join Date

- Mar 2018

- Location

- Turangi

- Posts

- 1,373

I have also had a couple of stainless Howas that rusted faster than any blued rifle I have ever owned.

Last one I had I gave it a really good coating and buffing with a soft cloth and "Flitz". Commonly used to protect knives and I believe also in museum restorations.

Really buffed it in and did 2-3 coats. Never had a problem after that. Just a wipe down with a rag with Ballistol after drying. Out of stock if really wet, and every time I wonder when I last did it. Occasionally rub some more Flitz on it, probably unessential though.

Although now I just Duracoat everything I can from new with the airbrush (never been a fan of the shiny barrels etc) and quick exterior wipe after trip, again with Ballistol

-

01-07-2021, 08:02 PM #4

Springs are also made using bronze,copper,and monel tho not typically in firearms.

"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

01-07-2021, 09:13 PM #5

-

14-04-2024, 05:58 PM #6Member

- Join Date

- Mar 2022

- Location

- Catlins

- Posts

- 537

Have come across this issue with my mini recently. I did actually drown it when I tipped over in a creek but it was showing surface rusting over the action, bolt, and barrel even before that from just being damp one day. Never struck this in my Remy stainless’s but had it occur with the T3X. Thought Is was prudent to pull it from the chassis just in case and sure enough, it was a mess. Had already cleaned it up with the 0000 steel wool and oil before finding this thread but I think I’ll break it down again, really have a good look at it and sort some form of protection for it.

“Age is a very high price to pay for maturity”

“Age is a very high price to pay for maturity”

-

01-07-2024, 08:48 AM #7Member

- Join Date

- Dec 2023

- Location

- Marlborough Sounds

- Posts

- 92

My stainless Howa was getting a few rust marks on it so I chatted to Murf about Cerakote colours and he recommended just blasting it and seeing how it goes.

Theory been the more matte finish holds oil better and I've found this true, even living next to and using this rifle near the sea.

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

43Likes

43Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks