Hey team.

I recently bought a new to me maniatis suppressor off this awesome forum. Sadly it is about an inch too far back for my bell and Carson stock. Rather than do the sensible thing and just keep using my DPT, I have decided to resurrect my failed powlonia stock project. I would really like to compare the two suppressors side by side and keep the one I prefer. I also run a dpt on my 708, so if I keep the Maniatis I eliminate the possibility of accidentally grabbing the wrong suppressor!

I really like the shape and size of the Maniatis, and it has the added benefit of reducing the overall length of my rifle by nearly an inch.

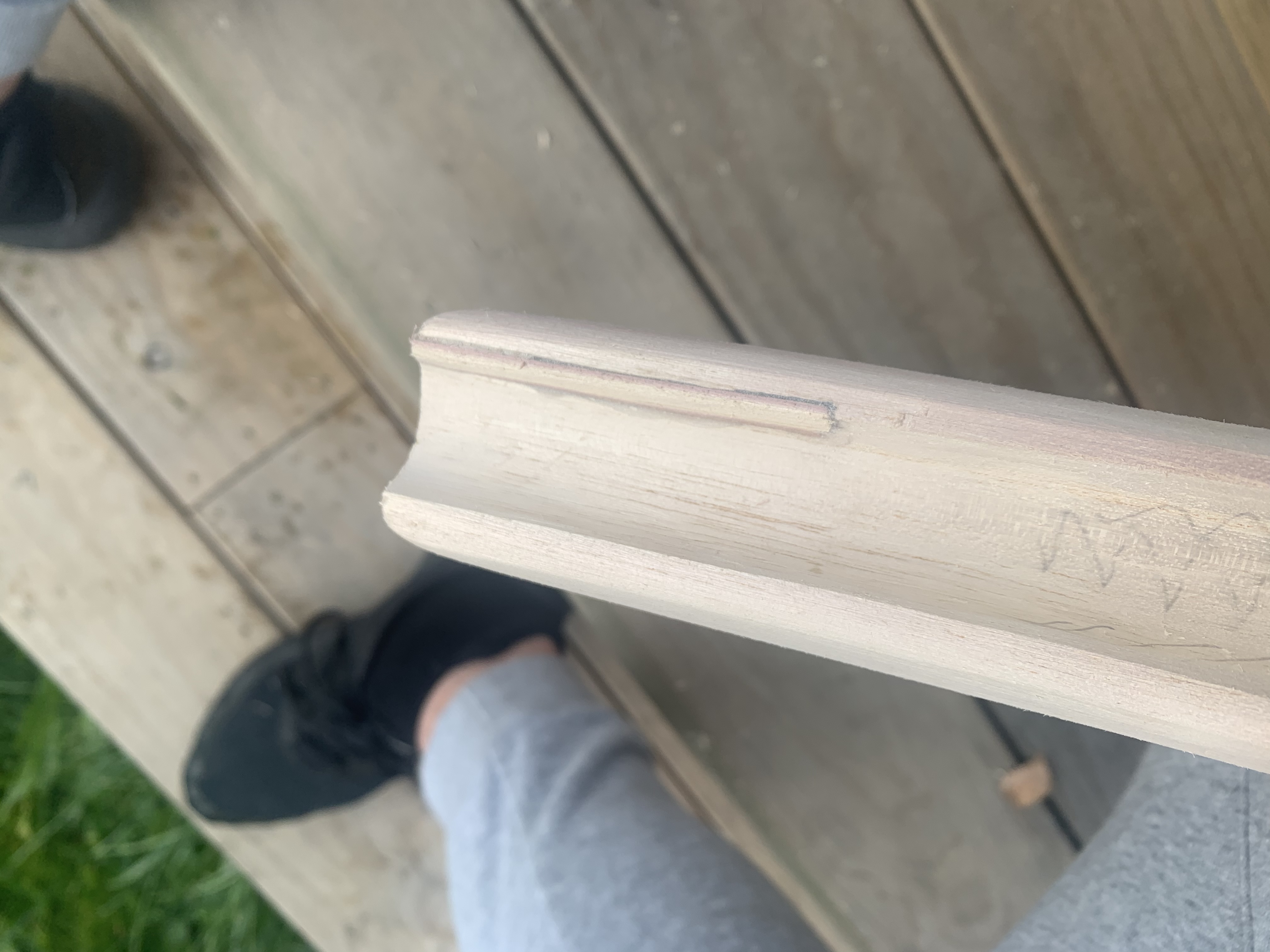

The last time I was working on the stock I got a little too enthusiastic with my chisel, and opened out the barrel channel a touch too much. Iím my own worst critic and put the stock aside in disgust, and bought the B&C stock my rifle is sitting in at the moment.

As can be seen in the photos the gap is decent, and if I kept it like it is it would forever annoy me.

The eventual goal will be to carbon wrap the stock, so if I can fill in that gap with something, I can trim the carbon to even the whole channel up for a nice clean finish.

Does anyone know of a suitable putty like substance that would harden up when set that I could use for the structure under the carbon?

Or I suppose I could simply open up the other side so they are even and just say I designed it like that 😂

Although as I write this it occurs to me that I could take a sliver of powlonia off cut and glue it into the channel, then simply reshape it to the desired thickness.

I think I have just answered my own question hahah!

Regardless I would appreciate your input!

Cheers team

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 11 of 11

7Likes

7Likes

Thread: Woodworking gurus

Hybrid View

-

21-05-2022, 05:19 PM #1

Woodworking gurus

-

21-05-2022, 05:24 PM #2

that is barely free floated..open the other side up...get stuck in and give it a sanding...will make it much smoother and give a couple or three coats of polyurethane. your barrel channel is tiny compared to mine.....but then the seuz cannal isnt much wider!!! and it still works.

75/15/10 black powder matters

-

21-05-2022, 05:47 PM #3Member

- Join Date

- Aug 2019

- Location

- Manawatu

- Posts

- 1,061

Key factor to remember with fillers, is matching it to the relative density of the wood. If the filler is too hard, you’ll find yourself removing too much wood around the filled area. Especially with that timber you have there. Epoxy mixed with micro balloons would be ideal.

-

21-05-2022, 07:22 PM #4

I opened the barrel channel right up on mine. I donít like how moisture sticks between the stock and barrel when in the hills. It also gives me options to rebarrel later.

I filled in a couple of mistakes by mixing the paulownia dust/shavings with epoxy. Doesnít have to be pretty because it gets covered by the carbon wrap anyway.

I was told an old trick is to mix pva glue with wood shavings to act as a filler however it wasnít solid enough for my liking.

-

21-05-2022, 08:09 PM #5

Yeah I do remember that as a way to fill gaps. Might give that a crack.

Obviously it’s still rough as and needs a lot more shaping/sanding. I’m happy where the action is sitting at the moment. Feeds flawlessly.

I’ll bed the stock first to lock the action in place, then once that’s done I’ll open the channel up a touch.

Appreciate the advice team

-

21-05-2022, 08:16 PM #6

just be aware its VERY easy to bugger it up from here.....that wood is so soft you can very easily take to much away and once you take it away,you cant put it back...I ended up placing a steel washer in between the stock and action till got height back to where it needed to be...the critical clearance on the magazine was harder to maintain... at one point I could feed an extra round....

75/15/10 black powder matters

-

22-05-2022, 12:34 PM #7

Yeah for sure, that’s why I’m going to bed the action first before I get too carried away with the free floating. It pretty much is free floated now, but just in case there is a small piece holding the action where it is, I’m going to make sure. I have the rifle feeding perfectly currently, and want to maintain that

-

22-05-2022, 09:14 AM #8Member

- Join Date

- Sep 2013

- Location

- Wairarapa

- Posts

- 1,427

I havenít worked with paulownia, it looks fairly soft. I have used sanding dust from the stock and mixed it into Araldite, spatchcock it into the gark and sand smooth, sometimes it comes out looking like a nice knot in the timber. Probably wouldnít look great on your situation though. I would vote to just even the other side up, job done.

OrÖ cut it off and put an ebony forend tip on there.

-

22-05-2022, 03:08 PM #9

I use paulownia for my fishing lures, for any filling work i use epoxy and glue powder, i mix it until it doesnít drip off an ice-block stick. Spread it on then sand back

-

30-05-2022, 07:11 PM #10

I cut it further back and epoxied a piece of powlonia on there, then shaped it back. Came up mint

-

30-05-2022, 07:31 PM #11

If all goes wrong ... get a gunsmith to turn you a thread adapter to make the Maniatis ride an inch further out.

An itch ... is ... a desire to scratch

Similar Threads

-

GPS gurus

By The bomb in forum Gear and EquipmentReplies: 7Last Post: 23-05-2021, 10:51 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks