welding 50 x 2 with a buzzbox is going to take some deft handwork!

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 50

Thread: homemade ATV Trailer advice

-

28-06-2023, 09:24 AM #16Member

- Join Date

- Jul 2020

- Location

- Central North Island

- Posts

- 5,366

-

-

28-06-2023, 10:05 AM #17Member

- Join Date

- Nov 2022

- Location

- Dunedin

- Posts

- 718

Hmm okay bugger. I deliberately went 2mm instead of thicker to save weight. I figured it would be okay for a lightweight trailer that will likely never carry a heavier load than about 300kg. And the Honda can't handle a heavy tongue weight anyway, so ill be taking care to evenly distribute heavy loads.

I shoulda posted on here before I ordered the steel!

-

28-06-2023, 12:58 PM #18Member

- Join Date

- Jun 2022

- Location

- Papakura

- Posts

- 1,631

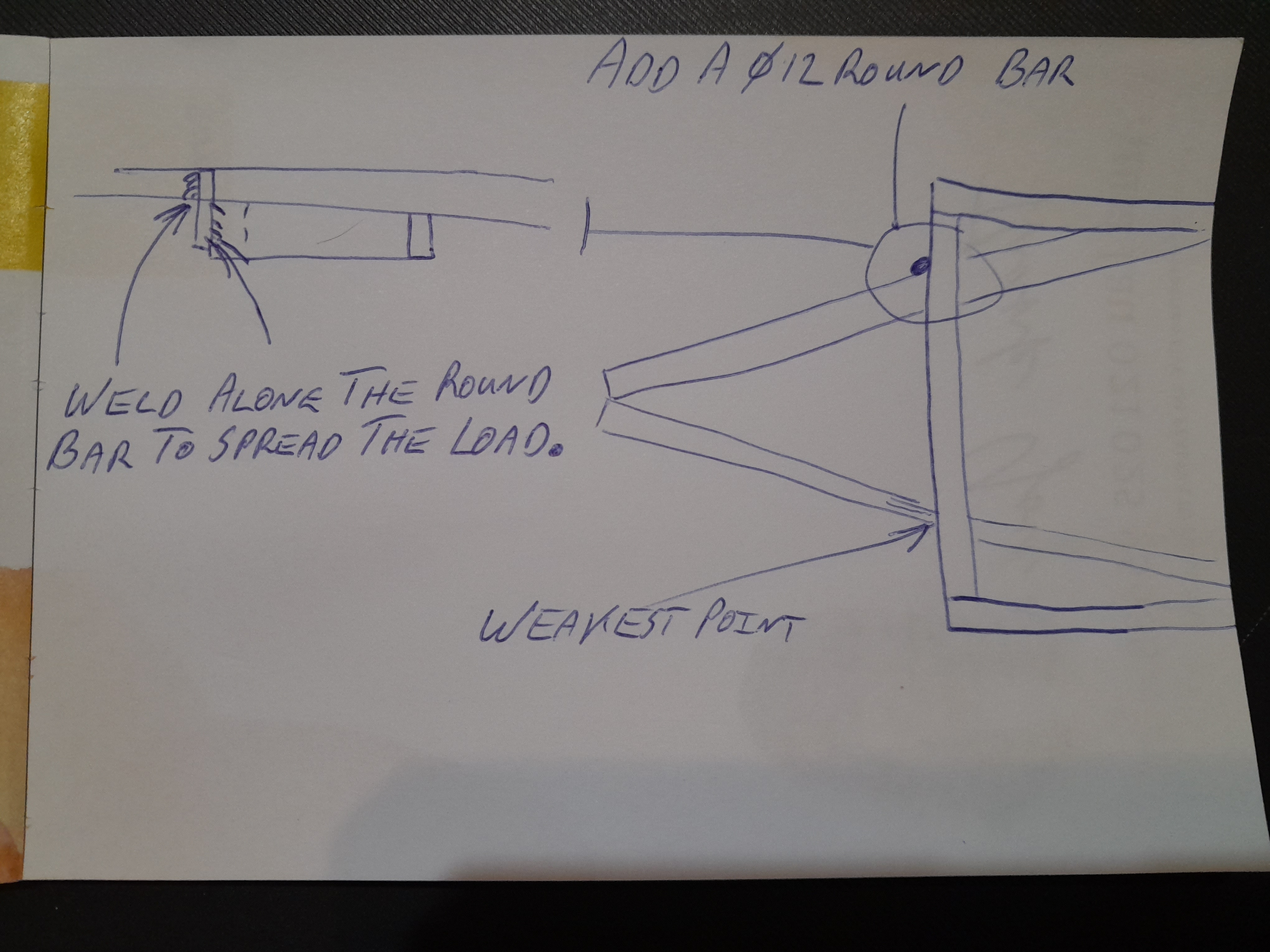

Don't stress too much about the steel been too light. I've made many projects that had weight as the major limiting factor and I've even been surprised at how well they worked out. As you've ordered the steel just try to give it a go, welding the lighter tube is easy enough with a MIG welder and just add gussets (I'll post a quick sketch later) where the frame meets the drawbar as that is the bit that'll get the most flex strain and risk of the weld tearing through the tube wall.

-

28-06-2023, 02:16 PM #19Member

- Join Date

- Nov 2022

- Location

- Dunedin

- Posts

- 718

These look like just the ticket: https://twlnz.co.nz/hub-stub-kit-150...ini-145mm-hub/

Should fit standard atv wheels too, with 4 studs

-

28-06-2023, 06:47 PM #20Member

- Join Date

- Aug 2021

- Location

- Opotiki

- Posts

- 93

i built one quite similar to your design brad (25 years ago) but i ran the "A" right out to within about 15 mm of the outside of the tyres so in rough going the wheels can't snag on anything. also, and i believe importantly, i put the wheels quite away back so even climbing, the loaded trailer transfers weight onto the quads back wheels which helps out a lot , especially with a little 300 doing the work. 50 x 50 x 3 angle and only now rust is giving it a run for its money.

-

28-06-2023, 07:49 PM #21Member

- Join Date

- Nov 2022

- Location

- Dunedin

- Posts

- 718

Hey that's a good idea with the A-frame. I designed it this way so the A-frame would provide structural support right to the back of the deck - if I'm interpreting your message correctly yours would be a wider A-frame that only runs halfway down the deck? That would be less structural. I like the idea though - maybe I could keep my design but weld deflectors in front of the wheels? I wasn't planning to use mud guards.

-

28-06-2023, 08:37 PM #22Member

- Join Date

- Jun 2022

- Location

- Papakura

- Posts

- 1,631

Here's a really rough sketch of where to put the gussets. With thin wall tube it's more likely to tear the tube just beside the weld so 2 bits of round bar will spread the load across a larger area.

-

28-06-2023, 08:40 PM #23

consider running a heavier beam right up the guts..between your A frame....and if really really clever put slightly smaller box section inside it wit hyour tow hitch attached with a couple of different hole depths to drop bin and lynch pin in..that way you can make it long for easy turning /backing int o shed etc.. the longer the slower it turns... by chucking it right up the guts you strengthen deck too..best of both worlds with your Aframe still there. different wheel base actually has an advantage...it will help flatten out your farm tracks instead of just making ruts deeper..one thing the old trikes were awesome at fixing.... a long drawbar is also easier to lift..having pinged my back on atv trailer its a sore point with me.

75/15/10 black powder matters

-

28-06-2023, 08:54 PM #24

Get rid of the A-frame and just run a single piece of box section straight back down the middle, it gives you a tighter turning circle which is handy on the farm. You could use the rest of the length of steel for your axle. Lots of quad trailers are built like this.

Use Duragalv steel and zinc paint the welds.

Don't put the axle too far back, you want the trailer carrying the majority of the weight rather than overloading the rear axle of the quad.

-

28-06-2023, 08:57 PM #25Member

- Join Date

- Aug 2021

- Location

- Opotiki

- Posts

- 93

just measured my one - 550mm of drawbar then 2 metres of deck. the axle is 1.4 metres from the front of the deck so the quad takes a good proportion of the trailer load. one disadvantage is when you are just about to hook it on to the towball and 30kg of speeding Huntaway lands on the front of the trailer...

-

28-06-2023, 09:03 PM #26Member

- Join Date

- Nov 2022

- Location

- Dunedin

- Posts

- 718

Thanks for taking the time to draw that up No good names left. Think I understand it, I'll see if it needs extra strength when we start putting it together.

MD, that's a good idea but much too fancy for this cheap and cheerful trailer! I will have leftover 50x50 though, so I could add a third length running right down the middle. Ill decide whether it needs it at the time. Good point about track width.

-

28-06-2023, 09:11 PM #27Member

- Join Date

- Nov 2022

- Location

- Dunedin

- Posts

- 718

Savage1, I'll probably use an A-frame because it will be only 2mm steel so the extra strength might be needed. The design should be a pretty narrow a-frame so hopefully it won't interfere with my turning circle.

The measurements I've worked out have 1m of drawbar in front of the deck. And the deck length is 1600. So 1800 overall from hitch to axle. Should be plenty long enough I reckon, and allows a pretty narrow a-frame which runs right to the back corners of the deck, as shown in my drawing.

Apparently the trx300 only has a 30kg tongue weight limit for trailers. That's pretty light and any trailer would have to be well balanced to not exceed that! The hen house I tow must weigh nearly 80kg at the tongue I reckon. I think I'll put the wheels pretty close to the centre so it's not too front heavy, but I would've thought how I distribute loads in day-to-day use would matter more than anything.

-

29-06-2023, 07:20 PM #28Member

- Join Date

- Apr 2020

- Location

- ashburton

- Posts

- 119

we used to tow 2 big bales on our calf trailer back in the early 2000's including trailer total weight was probably 1000kg easy.

the old 300's will just keep going so dont worry about making the trailer a bit heavy,

my drawbar and axle is 50x50x5, wheel pattern is 100x4 like my quad and using 250kg springs designed for a jetski.

of course the design is different from yours but the frame will still be the main carrier of the weight

i had a 40x40x3 towbar but that didnt last

-

29-06-2023, 08:19 PM #29Member

- Join Date

- Jan 2020

- Location

- porirua

- Posts

- 852

built this in 2011 used 5 stud ford hubs but knocked out 1 stud and was able to redrill honda wheels at a later stage to suit which meant I could used trailer wheel on quad . The mazda wide mags worked well on sand [ note the wooden guards that made great bait boards we called it the chariot of the dogs .

built this in 2011 used 5 stud ford hubs but knocked out 1 stud and was able to redrill honda wheels at a later stage to suit which meant I could used trailer wheel on quad . The mazda wide mags worked well on sand [ note the wooden guards that made great bait boards we called it the chariot of the dogs .

-

10-07-2023, 11:44 AM #30Member

- Join Date

- Feb 2022

- Location

- Nz

- Posts

- 1,171

Hows the welding going Brad's??

Similar Threads

-

Homemade Ice cream

By mrs dundee in forum Game Cooking and RecipesReplies: 17Last Post: 16-05-2015, 01:13 AM -

Homemade bread...

By EeeBees in forum Game Cooking and RecipesReplies: 12Last Post: 07-01-2015, 12:00 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

41Likes

41Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks