Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 46 to 60 of 62

Hybrid View

-

16-05-2024, 10:54 PM #1Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,883

-

18-05-2024, 08:02 PM #2Member

- Join Date

- Feb 2022

- Location

- Nz

- Posts

- 1,166

-

16-05-2024, 09:11 PM #3Member

- Join Date

- Jul 2020

- Location

- Central North Island

- Posts

- 5,272

It would make a grand centrepiece to a North Island forum get together

-

16-05-2024, 09:25 PM #4

-

16-05-2024, 10:53 PM #5Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,883

-

16-05-2024, 11:17 PM #6Member

- Join Date

- Jan 2020

- Location

- porirua

- Posts

- 846

reverse down boat ramp and hit both pedals with ya big wader boot , in the sea of course .

-

16-05-2024, 11:50 PM #7Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,883

It's got three peddles - last time I tried jumping on everything it just stalled and stopped dead... That trick is a lot more spectacular when you try and grab the clutch peddle but forget that you've jumped into an auto - just about put one of my old workmates through the windscreen accidentally one day doing that! The sea is an option though I suspect it will be like moses, and drive on to the outer islands dry, but with fish flopping all around. I'm still not convinced fire will cleanse it too.

I'm fairly sure the pile of destroyed sensors and parts off it will burn though - that is an option. Now if I could just work out what's making the weird electrical buzzing noise under the steering column I think we would be one step closer to the culprit.Last edited by No.3; 16-05-2024 at 11:55 PM.

-

17-05-2024, 08:29 AM #8Member

- Join Date

- Jul 2020

- Location

- Central North Island

- Posts

- 5,272

-

17-05-2024, 07:20 AM #9Member

- Join Date

- Jun 2023

- Location

- waimakau

- Posts

- 4,326

They havnt built a proper ford since 1970

-

17-05-2024, 09:09 AM #10Member

- Join Date

- Jul 2020

- Location

- Central North Island

- Posts

- 5,272

Rogue electrons are only one sort of disaster modern automobiles suffer from. In Europe they are attempting to further 'green' their cars by replacing petrochemical insulation with Soy based items. Cue animals that like soy......

https://www.youtube.com/watch?v=8sT-ZReOkNs

-

17-05-2024, 09:13 AM #11

-

17-05-2024, 09:44 AM #12Member

- Join Date

- Jan 2019

- Location

- Havelock/Linkwater or Ashburton Lakes

- Posts

- 703

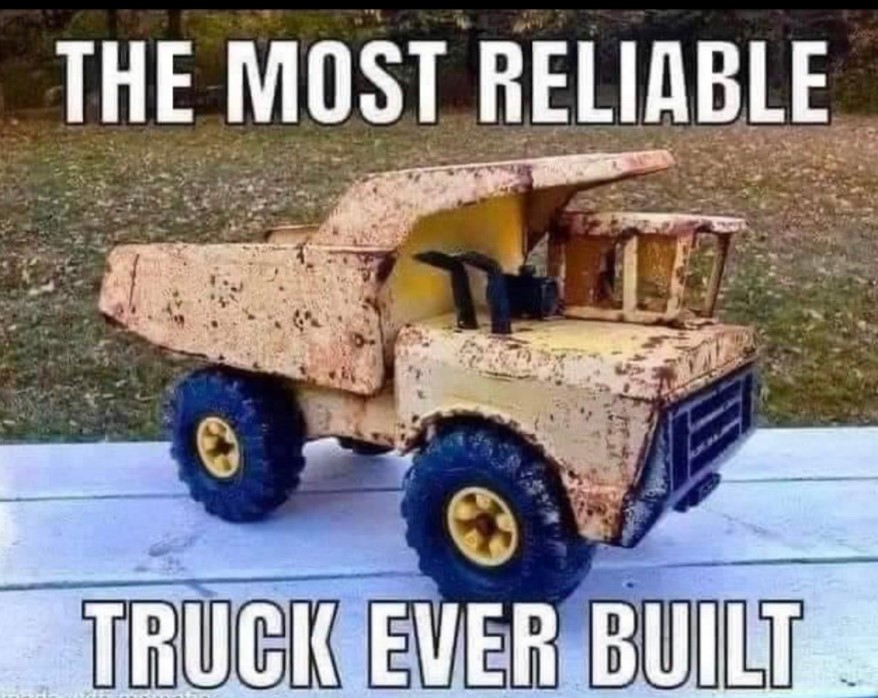

Remember when trucks were reliable and no one fought over who's truck was best as they all were great.

-

31-07-2024, 03:26 PM #13Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,883

Time for an update I think - so far the list of components I've replaced on this vehicle is up to:

PCM Powertrain Control Module - this thing runs the engine basically. It had a damaged 5vDC output regulator - this runs the sensors on the engine etc.

BCM Body Control Module - main ECU basically. The vehicle has two networks, high speed and low speed and this is the only place the two networks intersect.

IGCM Instrument Gauge Cluster Module - this has a CANBus hub in the back of it and that hub wasn't talking basically. This is likely the cause of the generic fault codes and limp mode issues

Fuel Pressure Regulator or SCV - electrically damaged

Throttle Body - throttle flap position motor electrically damaged

Fuel rail pressure regulator - pulled to check due to performance questions, found that Ford factory had literally dipped the end of it in thread sealant. The hole in the sender was blocked with crystallized thread sealant and the bottom half of the common rail was full of thick white jelly which looked to be diesel hydrolised thread sealant. Thanks Ford...

Two injectors, one electrically buggered and the other partially blocked (got a set of five in it - testing the injectors and fitting replacements has been the most expensive part of the work so far)

Also bypassed and deleted the EGR as part of this set of works.

Seems to have cured the issue - waiting on a compact split-style hall effect current sensor to do a final check on a couple of components and this style of sensor doesn't seem to be available in NZ that I could see. This will confirm if there are any other issues with a couple of the engine management components.

With the fuel consumption of this vehicle vs the equivalent new replacement in the same useage - it looks like the repair cost will be recouped in less than 50,000Km's just in the lower amount of fuel burned vs the newer auto-transmission vehicles. Worthwhile doing I think, but it does show the very real limitations in relying on on-board OBDII diagnostics on these vehicles. When the issue is in the CANBus communications network and computer side, modern parts-swapper 'mechanics' seem to be completely out of their depth. It has taken a long time to gather the evidence to support the theory that this was not a mechanical issue in the fuel injection system.

Similar Threads

-

Xmas bbq sorted

By The bomb in forum The MagazineReplies: 6Last Post: 17-12-2023, 09:51 PM -

Dillon 650 sorted

By Tikka7mm08 in forum Pistol ShootingReplies: 9Last Post: 13-06-2020, 11:44 PM -

The boys sorted

By veitnamcam in forum Gear and EquipmentReplies: 16Last Post: 02-05-2014, 10:32 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

81Likes

81Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks