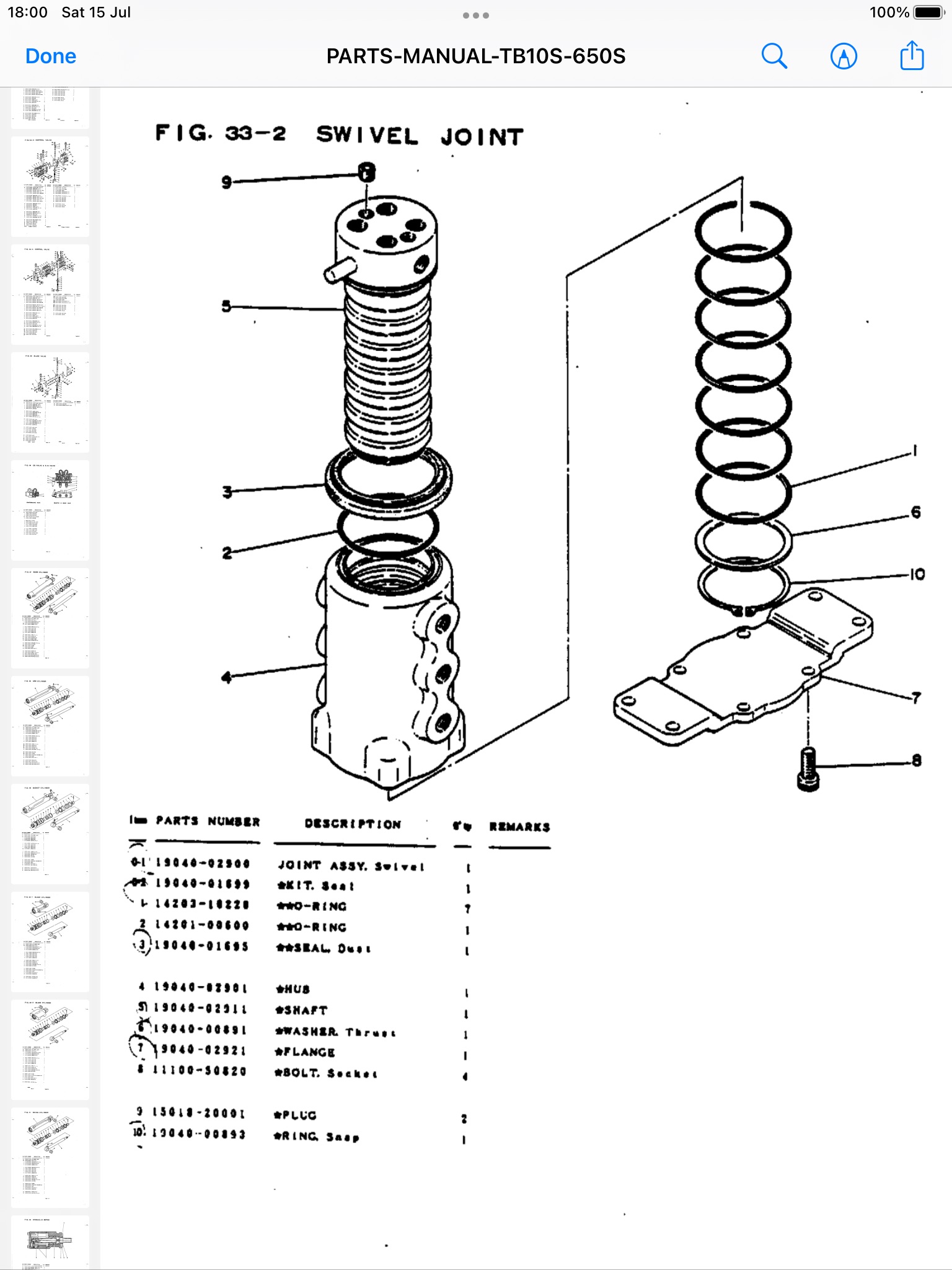

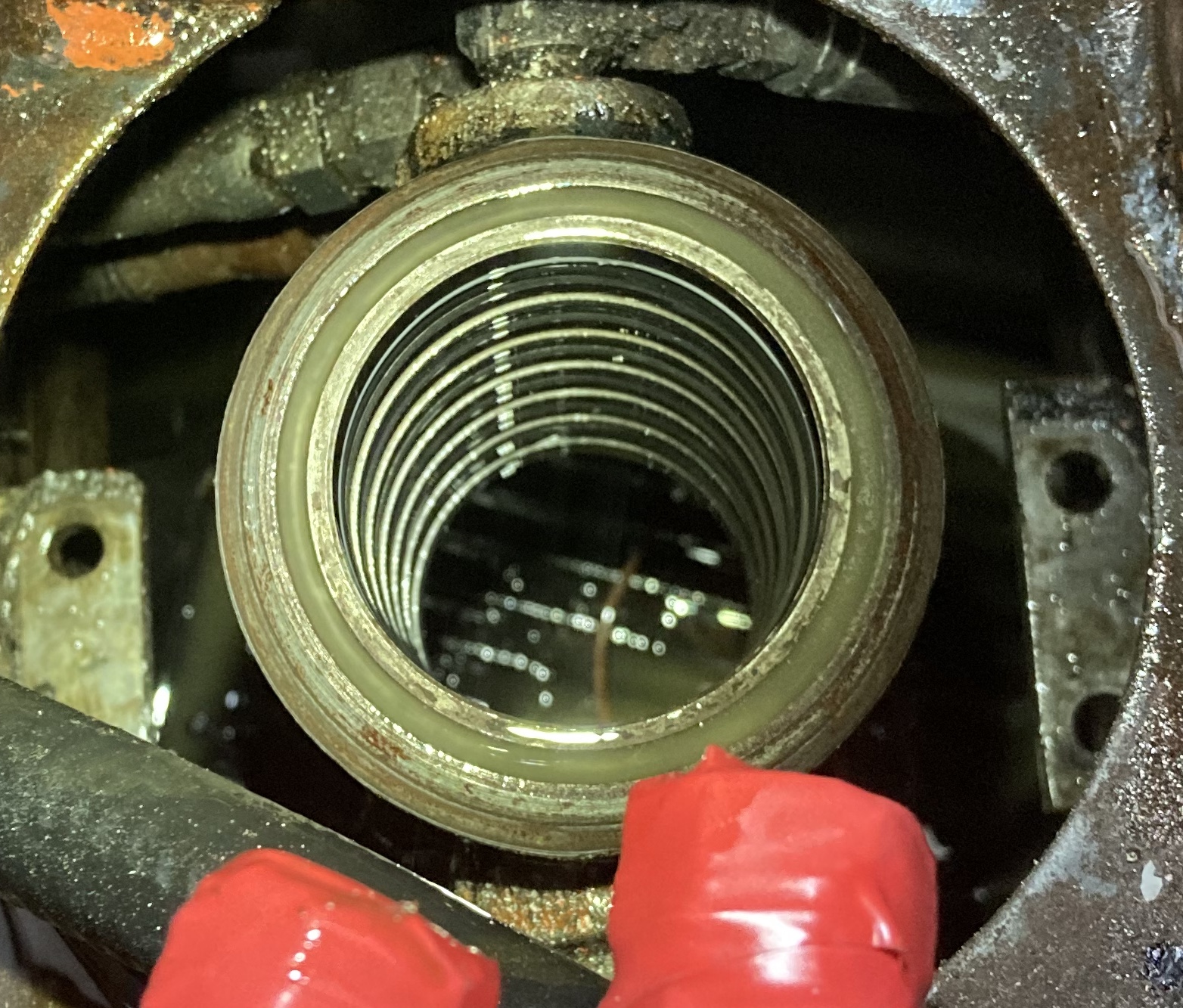

Anyone have any experience servicing hydraulic swivels? My > 25 year old Takeuchi is leaking out of from the top circuit which is the blade ram. I have a manual but the OEM parts are pretty much not available any more so Iím looking for info on how to measure up for replacement O-Rings. I can get an accurate inside diameter from the shaft but the outside diameter is tricky, I donít think I can snap gauge the grooves in the hub for depth. Any ideas or is there a common formula?

Ta, Ray.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 13 of 13

12Likes

12Likes

Thread: Mini excavator centre pivot/swivel help

Threaded View

-

18-07-2023, 08:07 PM #1

Mini excavator centre pivot/swivel help

10MRT shooters do it 60 times, in two directions and at two speeds.

Similar Threads

-

Excavator Relief adjustment

By Tentman in forum Outdoor TransportReplies: 15Last Post: 16-02-2024, 09:51 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks