I was rather worried about this bit, stuff it up and thats game over for the handle and you need another piece of wood and liners, the tang came predrilled with three holes, one for a brass tube for a lanyard hole and two for bolts to attache the handle to the tang.

I tied to get a step down drill bit, which would allow me to drill two sizes in one go, but like a lot of old tools these seem to no longer be made, I considered getting an engineering company to grind down an existing bit to make one but decided that was going to far for one knife...

So I figured I would just drill the 4mm hole for the bolts and then an 8 mm hole half as deep for the nuts. I was very worried about accuracy as I tend to find when I drill it rarely goes straight, so I started pricing up drill presses. Way too expensive, but a drill holder is a different proposition, this device uses your existing power drill and hold it in position, then with a lever on the side you can use it like a drill press and for $40 it was a steal, took a few minutes to set up, a few more to fix as the reason its so cheap is that the bolts appear to be made from polystyrene and I stripped one straight away, and then a few more to get the measurements right.

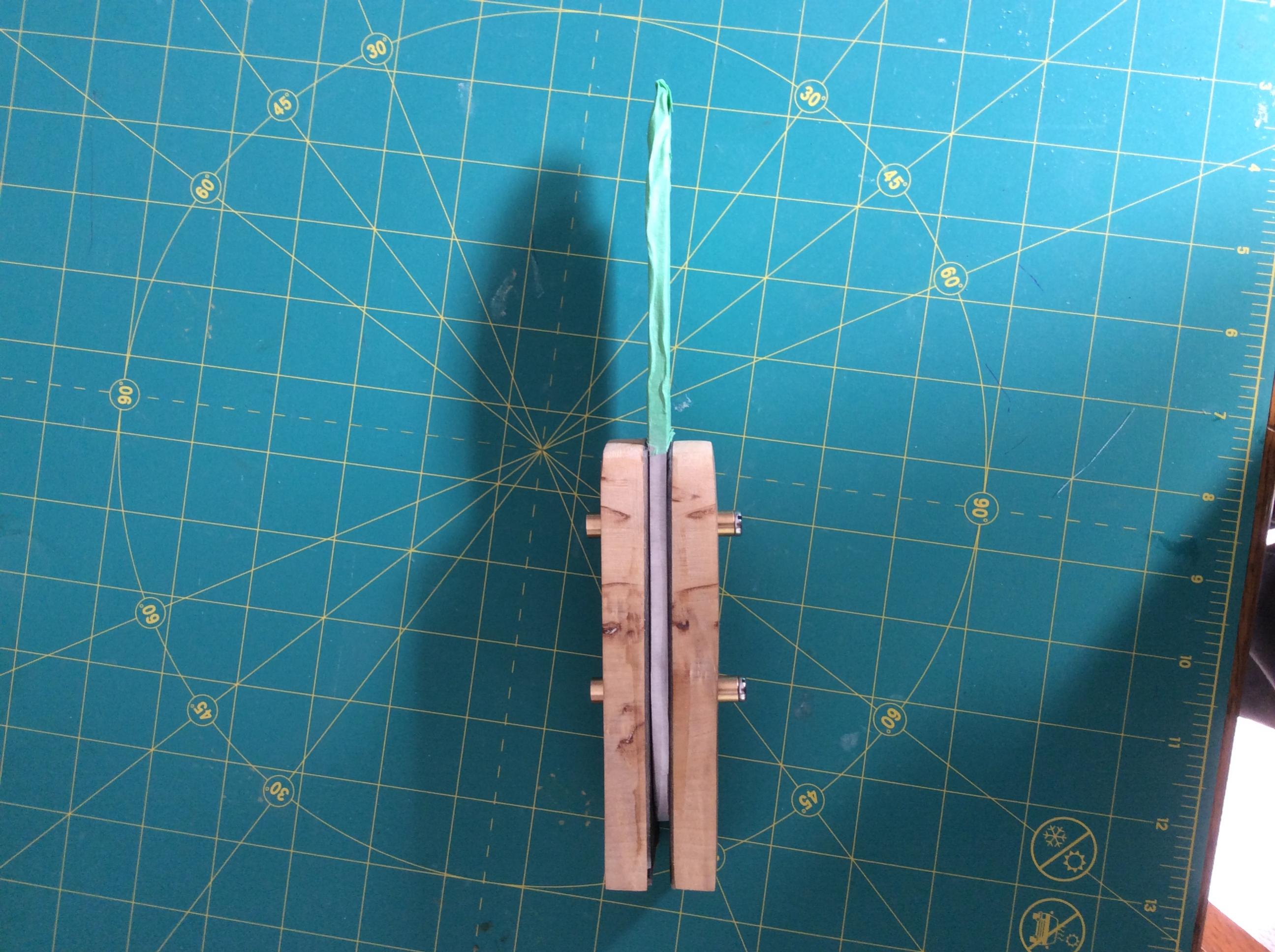

Next was clamping the blade to wood in the right place, and once I was satisfied drill the first 4 mm hole, went smoothly, place a the bolt in there to hold the space, repeat with the second hole and bolt, then swap the bits and drill the lanyard hole.

So far so good, then remove the blade, line up the pieces of wood and drill through the existing holes and out the other side, then test, and everything worked.

Was quite chuffed so went and put the bigger bit in and set the depth for 7 mm and drilled the bigger holes, and wouldn't you know it, it all fitted!

I had expected something to go wrong, but I guess when you have the right tools for the job then even a monkey can get it right sometimes.

Photos:

Next is shaping the scales

Shelley

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 3 of 3

Threaded View

-

07-07-2015, 10:32 AM #1Member

- Join Date

- Aug 2014

- Location

- Auckland

- Posts

- 719

making a knife and a sheath - part 3 drilling the holes

Similar Threads

-

making a knife and a sheath, part 2 - liners

By Shelley in forum Gear and EquipmentReplies: 5Last Post: 10-07-2015, 12:38 AM -

making a knife and a sheath - part 1 (assembly)

By Shelley in forum Gear and EquipmentReplies: 4Last Post: 05-07-2015, 01:33 PM -

New Pocket knife , new sheath

By Ground Control in forum Projects and Home BuildsReplies: 11Last Post: 06-01-2014, 01:29 PM -

Folder knife sheath I made today

By Ground Control in forum Projects and Home BuildsReplies: 14Last Post: 17-12-2013, 07:10 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

1Likes

1Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks