D2 is certainly "good enough".

Any half decent steel should be up to doing a complete bone out of a deer in the field without touching the edge, and D2 can do that. The risk of a chip on a stone or bone is higher than with a lot of other steels though.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 36

-

03-06-2020, 10:19 PM #16Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,574

-

-

03-06-2020, 10:33 PM #17

@Tahr if you had to rate knife steels for field use what have you found best / worst in terms of both performance and ease of sharpening?

-

03-06-2020, 11:11 PM #18Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,574

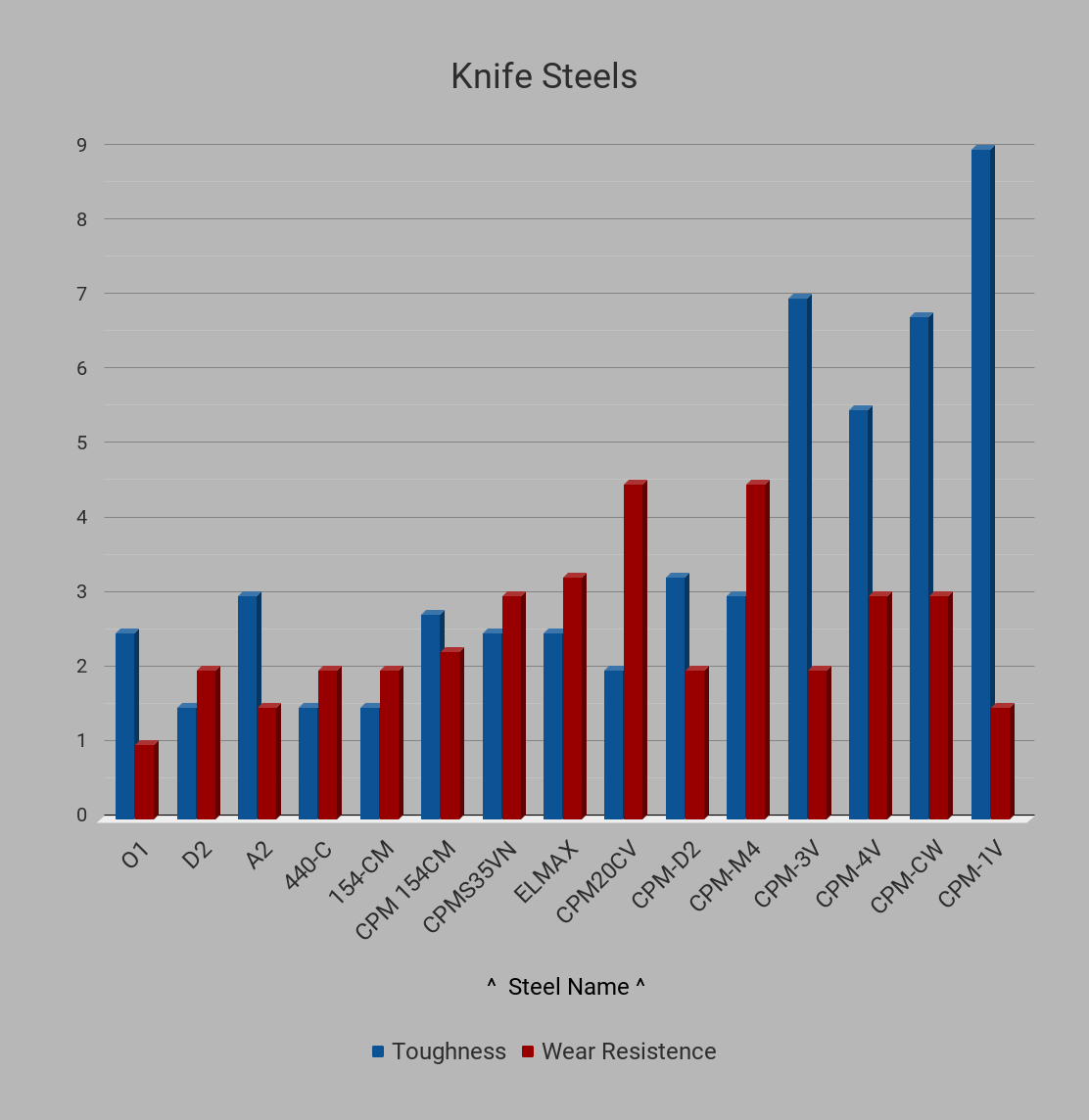

3V the best for all round features But just a lilt bit difficult to sharpen - but easier than D2.

A2 is a well balanced steel. Not the edge holding of 3V but still pretty good.

And for a real stonker that stays sharp for ever but can be more difficult to sharpen: 20CV. I have a couple and they are unbelievable.

Last edited by Tahr; 03-06-2020 at 11:21 PM.

-

04-06-2020, 04:07 PM #19

Cedric and ada on you tube definitely has the best steel testing regime for edge retention. Definitely worth looking up your favorite steel there.

Here's his list in order from best to worst

https://www.everydaycommentary.com/w...st-and-results

-

04-06-2020, 06:18 PM #20

I have 3 D2 knives my brother made me, a skinner, pig sticker (my go to) and a drop point deer knife. Yes a prick to sharpen but work well in the field. It was a hobby and he sold the odd one as well, especially his chef style ones, can post pics if any one is interested.

"ars longa, vita brevis"

-

04-06-2020, 11:16 PM #21Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,574

-

05-06-2020, 01:51 AM #22

-

05-06-2020, 08:08 AM #23

its all about the heat treatment and then the application.

I love D2 as an everyday kinda knife...are their better steels out there? Definitely.

I really enjoy N690 as its an affordable steel thats easy to sharpen and keep a pretty good edge.

One thing the OP didn't mention so not sure if it was performed, but would be interesting to see some photos after running that edge over a strop as the final step.Regards

Terry

https://www.knives4africa.co.nz/

Custom knife dealer

Authorised Nitecore Torch Retailer

NZ Distributor of Nano-Oil

-

05-06-2020, 12:30 PM #24

…might….ok, probably will - in time.

With diamond abrasive stones the difficulty to sharpen in my view is not a consideration that need be factored into a choice of blade steel. I have folders here in CPM-S110V and the previously mentioned CPM-20CV and CTS-XHP, and that all follow the same sharpening process for the same excellent end result as for the PSF27 pictured earlier.

This leaves the trade-off primarily between the properties of toughness, edge retention, and corrosion resistance, and to be honest there seem to be plenty of fully-stainless knife steels now available that push the limits across the full spread of the toughness – edge-retention spectrum. The remaining steels (tool steels) used for performance blades (3V, M4, Maxamet etc.) might not be no-care, but in the main, they too, have sufficient amounts of free chromium to reportedly only need an oily wipe down after use - the sort of maintenance most hunters would be used to applying anyway from the plain carbon-steel days.

By persisting with using sharpening abrasives of significantly lower hardness than diamonds, hunters are probably excluding many of the newer blade steels from consideration, or if purchasing them anyway, seem often enough to be reporting having difficulty in maintaining the edge.

The question of whether to continue using earlier generation knife steels probably depends on how frequently someone is prepared to be touching up their edge when butchering, and for carrying the extra weight of gear for doing this?

Answering this for myself: not any more, not now that it isn’t necessary.

As well as trying out a small number of latest generation steels when replacing my old knife, I also purchased a set of bonded diamond stones, threw out my accumulated collection of abrasives (that in that one purchase had all become obsolete) and have not looked back.

https://www.nzhuntingandshooting.co....-review-52321/

https://www.nzhuntingandshooting.co....v-steel-52926/

For what it’s worth these Venev stones get my strong recommendation. Bonded diamond stones have the abrasive right throughout a layer of binder, so unlike the plated diamond stones - such as the DMTs, where once the diamond is worn or comes off the backing then the stone has lost effectiveness - the bonded stones can be rejuvenated repeatedly by refacing to expose fresh diamond.

A follow-up also on another of the points raised in the OP; the folder below has an example of a double bevel as a result of a 0.5mm difference in the thickness between two of the stones I used. That results in just a 4moa change in the angle of application in my sharpener, but in the photo it can be clearly seen in the offset reflections off the two faces (maybe view the image with a bit of enlargement to see this). I either adjust the difference out, or in this case have left it – as the finishing stone is fortunately the thinner of the two (put your geometry hats on!)

-

05-06-2020, 01:44 PM #25

The thing with a mirror finish is that it looks pretty and as a result the edge is super fine and would therefore dull very quickly, how much is actually gained for the amount of work required to obtain that edge in the first place? As far as I'm concerned, the blade should effortlessly cut through whatever I need to cut, anything more than that is time wasted. (unless you're fascinated by mirror edges of course)

Regards

Terry

https://www.knives4africa.co.nz/

Custom knife dealer

Authorised Nitecore Torch Retailer

NZ Distributor of Nano-Oil

-

05-06-2020, 02:22 PM #26Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,574

Ive never kept a V edge. I always attack them with water stones and turn them into a micro convex. Those acute V angles aren't very slicy - you notice it when opening up deer skin.

But that's just me.

-

05-06-2020, 04:28 PM #27

As the forum's Bark River man, you're not allowed V-edges anyway. It would be considered bad form.

The desire to convex anything steel and remotely sharp is clearly a strong one.

-

05-06-2020, 04:40 PM #28Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,574

Nice

Nice  One of my great knives (in M390) and a major departure from BRiver is this https://trcknives.com/product/classic-freedom/

One of my great knives (in M390) and a major departure from BRiver is this https://trcknives.com/product/classic-freedom/

It had the classic V edge, but I had to attack it... you can see a little bit of the residual V edge towards the hilt.

Last edited by Tahr; 05-06-2020 at 05:07 PM.

-

05-06-2020, 05:37 PM #29

-

05-06-2020, 05:42 PM #30

https://duloknives.com/

Pricing is about the same as barkriver, in some instances cheaper.

Shannon steel labs made in the states steels used vanax, lc200n, k390

At 200 to 240 us dollars

Similar Threads

-

Knife Sharpening

By Paua Pete in forum HuntingReplies: 7Last Post: 11-01-2020, 09:36 PM -

EXCHANGE A BLADE KNIFE

By bigbear in forum Gear and EquipmentReplies: 9Last Post: 16-03-2019, 05:09 PM -

making a knife and a sheath, part 5 - attaching the handle to the blade

By Shelley in forum Gear and EquipmentReplies: 2Last Post: 18-07-2015, 08:23 PM -

Old school replacement blade knife

By ChrisF in forum Gear and EquipmentReplies: 2Last Post: 17-06-2015, 11:27 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

41Likes

41Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks