The gomtaro with 300 mm curved blade is faster with less effort than the straight blades too

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 256 to 270 of 622

Thread: show us your chainsaws

Hybrid View

-

03-12-2022, 10:34 AM #1Caretaker

- Join Date

- Dec 2011

- Location

- Hawkes Bay

- Posts

- 9,548

A big fast bullet beats a little fast bullet every time

-

03-12-2022, 11:21 AM #2Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,990

Got the folding Silky - think it's the F180? Brilliant little saw on wood - bones fark it near instantly though...

-

03-12-2022, 11:28 AM #3Caretaker

- Join Date

- Dec 2011

- Location

- Hawkes Bay

- Posts

- 9,548

Don’t drop them on your leg, 11 identical perfectly spaced cuts all competing to turn your sock red

(don’t ask

(don’t ask  )

A big fast bullet beats a little fast bullet every time

)

A big fast bullet beats a little fast bullet every time

-

04-12-2022, 09:17 AM #4Member

- Join Date

- Aug 2012

- Location

- Otago

- Posts

- 1,652

My chainsaw team - well, the wee GTA 26 is officially my wife's tool. It kicks arse and a lot of fun too.

The 230 I got brand new for a really good deal about 18 months ago. It gets used on an almost weekly basis around my block. Love it.

The older 390 only come out for the bigger stuff. Use to be my only saw but only gets used a few times year now when we drop a bigger tree."The generalist hunter and angler is a well-fed mofo" - Steven Rinella

-

04-12-2022, 10:20 AM #5Member

- Join Date

- Mar 2012

- Location

- Hastings

- Posts

- 2,890

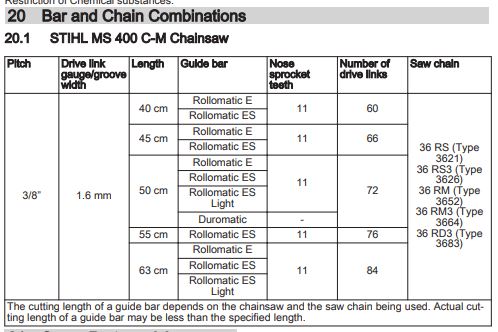

Any body running a Stihl 400?

-

04-12-2022, 10:45 AM #6

-

04-12-2022, 11:58 AM #7Member

- Join Date

- Mar 2012

- Location

- Hastings

- Posts

- 2,890

-

04-12-2022, 06:25 PM #8Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,990

I think that the fitment for the 400i is the same as the usual 3003 series for those size saws, if so the part number is 3003 000 9413. I have one here which I use on the 361. It goes OK but I use the 18 and 20" bars more as they are just better in terms of reach down when you are standing. Having said that, chain speed is wicked haha.

This is the manual snip for bar size so I think they are the same bars. Whether you can get one in NZ at the mo...?

-

04-12-2022, 08:54 PM #9

I am not sure what they sell them with, I just buy the powerhead and use sugihara bar's. I have a 16" on mine.

I rate the 400 over the 462 because of how light and well balanced it is, as well as how torqey the engine is. The 462 is a great saw but dosnt fit well between the 400 and the 500i in my experiance."Sixty percent of the time,it works every time"

-

04-12-2022, 12:49 PM #10

-

04-12-2022, 09:07 PM #11

Here is a size comparison.

From the bottom:

Husky 445

Stihl 400c looks like an Oregon bar on it

Stihl 441

Stihl 500i

Stihl 660

The 500i is to heavy for what you get, its to close to a new 661 to warrent using it for what I do. The 441 was a good saw but we always had problems with the m-tronic system leaning them out and roasting the rings.Thankfully they would always seem to die under warranty, if you got a good one they were a nice unit.

The 400 really impresses me."Sixty percent of the time,it works every time"

-

04-12-2022, 09:28 PM #12Member

- Join Date

- Mar 2012

- Location

- Hastings

- Posts

- 2,890

Cheers. Impressive line up .

-

05-12-2022, 07:47 AM #13

I love my 441, itís a really versatile saw. Must have got a good one, as I bought it new and itís done a full year waste thinning and multiple jobs over the last few years without a single issue. I use it over my 660 unless the tree is really big. Would love a 500 but donít use saws enough these days to justify it

Sent from my iPhone using TapatalkI'm drawn to the mountains and the bush, it's where life is clear, where the world makes the most sense.

-

05-12-2022, 09:23 AM #14

-

05-12-2022, 11:44 AM #15Member

- Join Date

- Jul 2020

- Location

- Central North Island

- Posts

- 5,339

Another one on the deck. Go the mighty 394

Last edited by XR500; 05-12-2022 at 11:56 AM.

Similar Threads

-

Because chainsaws vs zombies are old fashioned . . .

By Kscott in forum Firearms, Optics and AccessoriesReplies: 10Last Post: 18-01-2015, 08:16 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

878Likes

878Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks