Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 79

-

06-06-2021, 03:21 PM #31

-

-

20-06-2021, 10:56 PM #32

Muzzle thread and bore lapping

I have been working on some other projects, but am now back onto this.

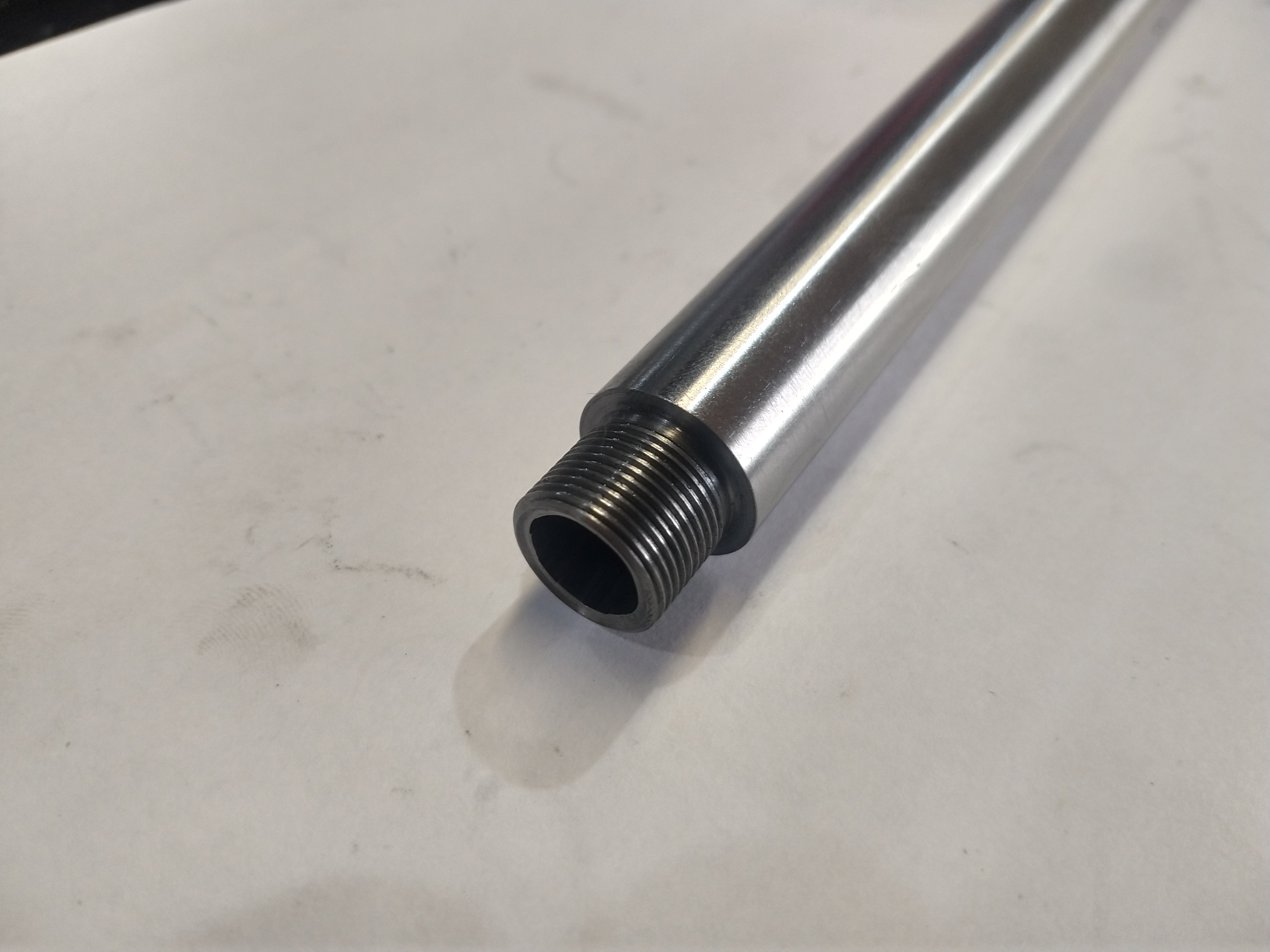

I needed to thread the muzzle before permanently installing it to the barrel adaptor as I would not be able to hold it in the lathe easily afterwards.

First I made a .450 bush for my bore indicating rod. I find this a good reliable way to get a bore dialed in without using horribly expensive long stem indicators. I get the run-out to zero at the muzzle and around 50mm down the bore. This ensures the thread and shoulder are square to the projectile flight path.

I chose 5/8-24 as the thread because I already own a tap that size that I will use for threading the suppressor.

Once the muzzle was threaded, I could start lapping the bore. The reason for lapping after threading is that the bore springs open very slightly when you remove the material to form the thread. You want the smallest part of the bore to be right at the muzzle, hence, lap after threading. This won't matter a damn on a 14" barrel open sight 45-70, but for most other applications requiring accuracy, it is a good thing to remember.

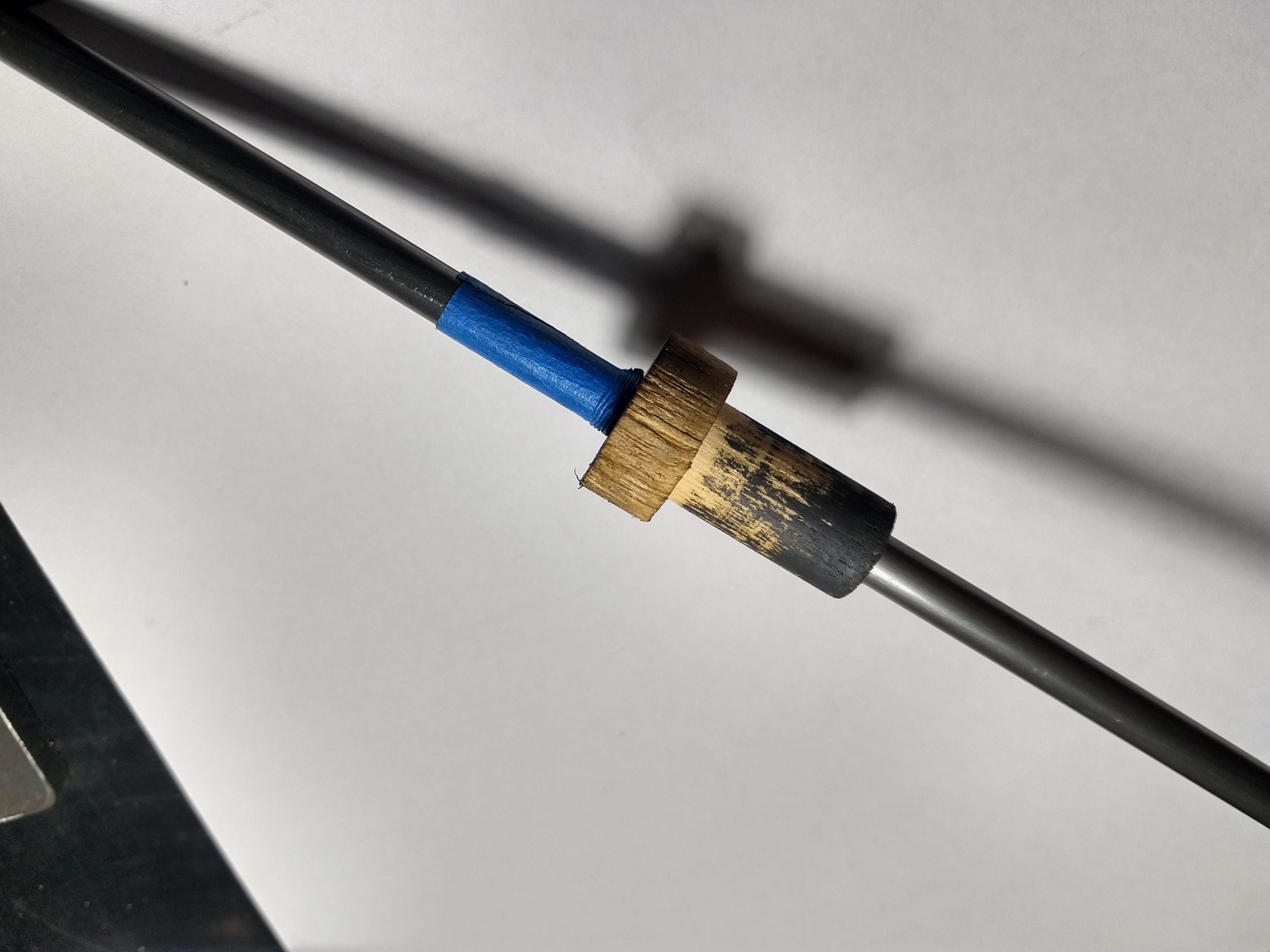

I made myself a nice handle for lapping that I can attach different diameter and length rods to. It is just a couple of bearings in a housing with some handles screwed to the side. Rough, but very effective. I also make a guide from timber whenever I am lapping a bore. This is to control the chamber end of the rod and stop it flexing and contacting the bore. Often, I make these a press fit into the action the barrel is attached to. In this case I made it a press fit into the chamber.

To make the lap, I wrap the rod about 30mm from the tip with a thick waxed thread used for leatherwork until it's a slip fit into the bore. This stops the molten lead running down the barrel. I then hold the barrel vertical in a vice and position the rod so the tip is around 20 - 30mm from the muzzle. I heat up the barrel with a heatgun and melt a little lead, which is poured into the bore once it is up to temperature. Once this cools, I poke the lap most of the way out and file some shallow grooves to hold lapping compound. It is then just a case of adding compound and getting to it.

When the lap starts to get loose, I bump it back to size by sliding a 10mm rod into the bore, running the lap down until it touches it, standing the whole lot on the floor and giving the back of the lapping rod a few smacks with a mallet. This swells the lap up the the size of the bore wherever it is positioned. In this case, I wanted more work to be done near the chamber, so bumped it near there. You can over do the bumping and the lap will be extremely hard to start moving again. A mallet helps it along.

By doing more lapping toward the chamber end of a barrel, you can introduce a very slight taper, with the tightest part being the muzzle. This is extremely important on .22lr barrels and I have noticeably improved the performance of a few .22lr rifles by taper lapping. For this rifle, it won't make a spot of difference, but it's still good practice.

I have some before and after photos from my borescope that I will upload later.

The next step will be to install the barrel permanently to the barrel adaptor. I am considering using epoxy rather than solder for this, as I have zero experience soldering things this large.

After that, I can start work on the sights and then the suppressor.

I am considering making a copy of the ranger point precision rear sight, as it would give me windage and elevation on the rear sight, along with sight protection and it being a relatively simple mechanism. I also think they look cool.

I would be interested to hear about any simpler sights that achieve the same thing.

-

20-06-2021, 11:25 PM #33

Very cool project man.

Are you going to drift the front blade for windage correction ?

The Skinner sights are effectively a lateral dovetail block, held in place by a grub screw. And the peep post is threaded into the block that slides in the dovetail, so you get some elevation in there. But they don't have any real sight protection. Can't say that has been an issue for me.Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

20-06-2021, 11:31 PM #34

On a side note, does anyone know if the barrels on Bergara single shots are attached in a similar way ?

I grafted a Skinner sight onto the back part of the Bergara BA-13 rail

Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

21-06-2021, 02:52 PM #35

Theoretically it should be as the bore does spring open. I don't know how much, but you can feel the difference when sliding a lubricated lead slug in the bore. I don't lap most barrels I work on. This barrel really needed it to smooth out the machining marks. It doesn't seem to make much of a difference on most rifles, or it would be more widely known.

The amount of material removed from most barrels is extremely small.

-

21-06-2021, 03:15 PM #36

I like the idea of having a rail there as well.

I am planning to have the front sight adjustable for windage, but was planning to use that as a rough setting and then fine tune it with the rear sight.

Do you find the half turn for elevation is a fine enough adjustment?

I'm not that set on sight protection, but if I'm making my own sight base, I might as well add it.

-

21-06-2021, 04:46 PM #37

The skinners use a strange thread, it is all UNEF. The apperture step is 10-40

I get roughly 2 MOA per full turn with that sight radius, so pretty happy with it. I've changed the rings on my scope to Leupy QD ones, so super easy to swop.

I ended up bringing in a bunch of UNEF taps (8-40, 10-40, 12-40 and 12-32) from KBC tools in the US - most expensive taps I own

Last edited by ebf; 21-06-2021 at 04:51 PM.

Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

21-06-2021, 07:55 PM #38

the ramp on top of action of the bakails makes a fair rear sight...just put small notch in it....my 12ga has deep V filed into it....works a treat.

-

21-06-2021, 08:42 PM #39

Great description of your lapping setup. I've looked into bore lapping before but never actually done it. Considered it for my problematic grey birch barrel to remove the bore constriction, but preheating the barrel before casting the lap would have been an issue with the carbon fibre wrap.

A couple of questions if you don't mind:

What grit are you lapping to?

I thought cut rifled barrels shouldn't open up when the OD is machined?

What I've read suggests that you normally lap before cutting the barrel to length, because the lap tends to bell the muzzle end where it exits and reverses. How are you avoiding this?

Really interesting to see this progressing.

-

21-06-2021, 08:43 PM #40

shoot lots of cast and it will do itself .......said the maker of them barrels LOL.

-

22-06-2021, 12:37 AM #41

-

22-06-2021, 12:40 AM #42The Original Striker

- Join Date

- Dec 2011

- Location

- waikato

- Posts

- 790

-

22-06-2021, 07:14 PM #43

I should make it clear im not a lapping expert. I have done a lot of research and reading about the subject, but have lapped less than 10 barrels so far, so take everything I say with a grain of salt.

What grit are you lapping to?

On a barrel that is not bad, I will lap with 320 and nothing else, If a barrel needs a fair bit of helping, I start with 220, and then just do a finish run with 320. Make sure to clean the barrel well between grits and cast a brand new lap.

I have read in multiple places that you dont want to go much finer than 320 as it actually increases the friction on the surface and can lead to very bad copper (or lead) fouling. I have not verified this myself, and its only been forum chat that suggests this, nothing from any real experts.

I made my own compound by buying silicone carbide powder if various grits from Rotorua lapidary Supplies. I then mixed up a batch for each grit with grease and with oil. I have found that grease is better than oil for barrel lapping. Any new grease will work.

I thought cut rifled barrels shouldn't open up when the OD is machined?

I have come across this idea myself. I believe they do open up a little with diameter changes as it can be felt with a slug. I have not checked my factory lapped Krieger (Which I believe are cut rifling) but I have come across it on a couple of other cut barrels that were known to be consistent before profiling/muzzle threading. I didnt lap either of these barrels and they both shot just fine.

Bill Calfees book has some information on the subject and he has documented that any change in the outside diameter of a barrel blank will result in a change in the bore size. This goes for receiver threads, barrel contouring, dovetails for sights and muzzle threading.

His book is appallingly bad and I struggled though it thinking there might be some information on the actual mechanics and tools involved in lapping. There isnt. Most of the book is him telling ego stroking stories that have nothing to do with improving rifles. There are a few tidbits here and there, but the good stuff could be covered in less than 5 pages, and its something like 200 pages long. That said, he is a proven gunsmith that has consistently turned out championship winning rimfire benchrest guns, so he cant be completely full of shit.

What I've read suggests that you normally lap before cutting the barrel to length, because the lap tends to bell the muzzle end where it exits and reverses. How are you avoiding this?

I dont extend the lap out the muzzle at all. I butt the muzzle up against something hard to stop the lap from extending out. I only push it out when I need to add more lapping compound. This will stop any bell-mouthing.

Considered it for my problematic grey birch barrel to remove the bore constriction, but preheating the barrel before casting the lap would have been an issue with the carbon fibre wrap.

The Pre-heat is probably only 150c. The carbon on your barrel should handle that just fine for a while. If it doesnt, then the manufacturer is using a type of resin that has no business being on a rifle.

You can sometimes get away with a lower temp pre-head, but the lap wont fill out as well. This can be fixed to a degree by a couple of good bumpings, just make sure you have the lap and barrel greased before you bump it, or you might get it stuck (dont ask me how I found this out)

Hope this helps.

-

22-06-2021, 07:18 PM #44

eagerly awaiting progress photos..........

-

22-06-2021, 07:55 PM #45

There you go.

Recoil pad is installed.

2600g (5.7lbs) at the moment.

Im trying to decide how to finish the barrel. The best would be having the barrel hot blued before installing it into the adaptor. next best would be leaving the adaptor blued and painting the barrel with black duracoat after installation. The simplest would be to just cold blue the barrel, but I have not had good luck with cold blue over the years.Last edited by SixtyTen; 22-06-2021 at 08:04 PM.

Similar Threads

-

New Baikal 121 Single Shot out

By Scout in forum Firearms, Optics and AccessoriesReplies: 15Last Post: 28-11-2020, 12:35 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

105Likes

105Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks