Cheapskate as ever, that's the fun of tinkering.

What do you do when your roll-on runs dry? Recycle its 33mm hollow plastic ball to go over a 20mm milspec one

Cut hole, a bit too small so cracked, never mind, had to superglue it into position anyway. Oversize hole used to squirt in gorilla polyurethane glue. this will expand into a lightweight hard matrix and extrude thhrough the hole. The material can be trimmed to size around the base of the knob, will be easier to do before it goes all hard. Then paint.

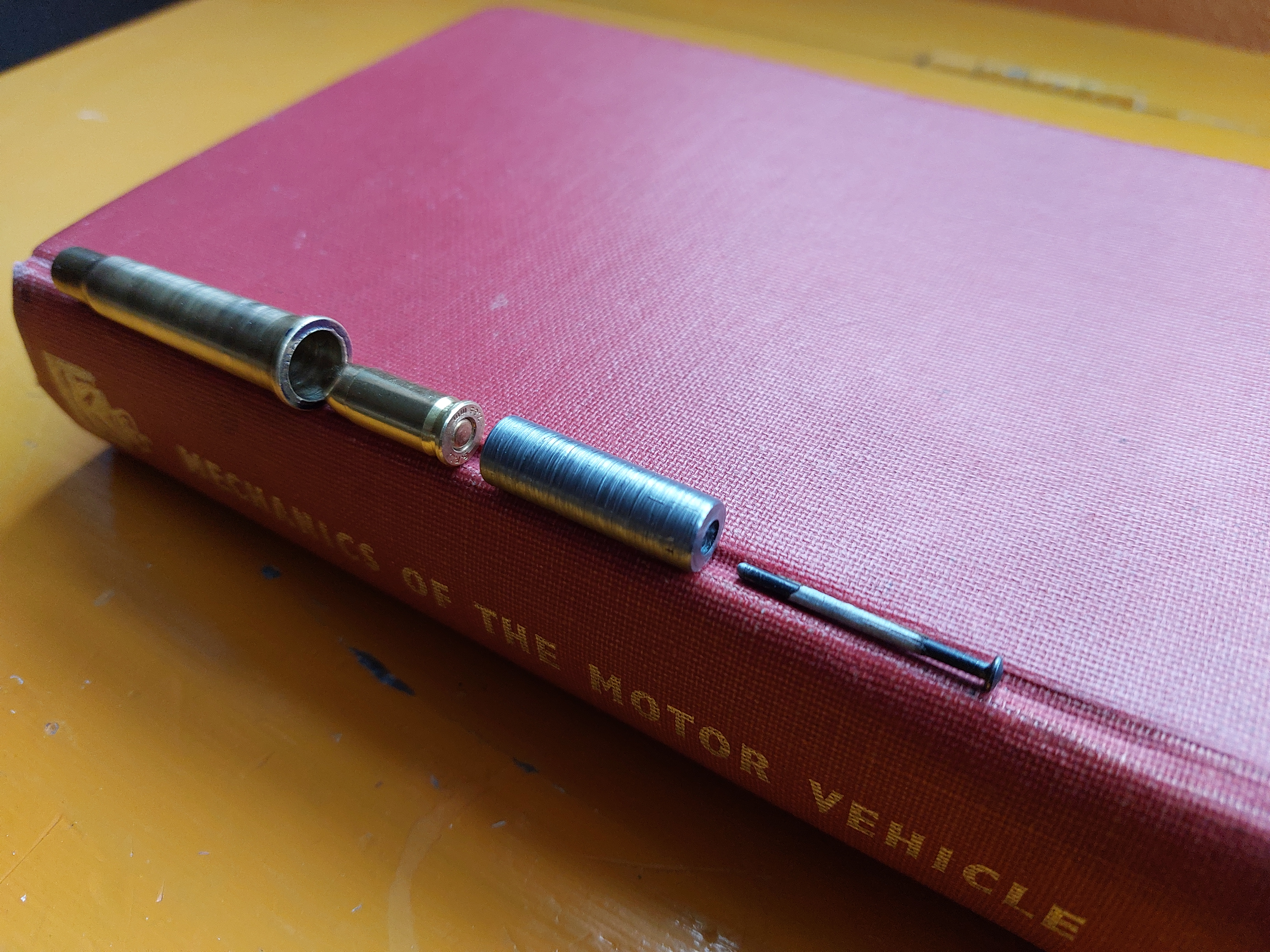

Second project today (which really makes zero financial sense given the prohibitive cost of 7.65x17 Browning, but one local range won't allow bottleneck cartridges). I have a 12G adapter for the 7.65 cartridge made out of an piece of .303 H barrel and it works fine in the .303 bore.

.303 case, 9.5mm drill out the rear, turn some black mild steel to fill the gap behind the pistol cartridge, drill a firing pin hole including pocket for the nail used for this. Round off the tip of the nail so it doesn't pierce the primer. I managed to tip the items on the floor several times already, including into a box of junk metal... )-:< so... a bit of tape to make the nail less prone to jump ship.

I'm thinking, I could also turn a groove in the breech piece for an 'o' ring to make it less likely to drop out of the .303 case.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 9 of 9

11Likes

11Likes

Thread: Bigger knob, shooting smaller bullets.

Threaded View

-

14-01-2023, 09:37 PM #1

Bigger knob, shooting smaller bullets.

An itch ... is ... a desire to scratch

Similar Threads

-

Removing 'leading' from shooting cast bullets

By -BW- in forum ShootingReplies: 9Last Post: 27-09-2022, 07:45 PM -

Bigger is better

By Greenie in forum Reloading and BallisticsReplies: 2Last Post: 07-01-2015, 10:11 PM -

Something bigger?

By StrikerNZ in forum Firearms, Optics and AccessoriesReplies: 52Last Post: 06-04-2013, 09:33 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks