To take a quote from a silencer forum I briefly became a member on "baffles are good".

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 26 of 26

-

02-12-2018, 09:48 AM #16Member

- Join Date

- Jan 2018

- Location

- kaiapoi

- Posts

- 7,437

-

-

02-12-2018, 10:34 AM #17

-

02-12-2018, 11:00 AM #18

Got a ~75cm lenght of galvanised 1 3/4" galvanised steel tube I found in my garden after former neighbour's trampoline blew across and dented my garage. Good place to start. Might do a really long counterbore on the SMLE and vent holes along the sides of the counterbore (think Madsen rifle). If she shoots OK I'll proceed further.

An itch ... is ... a desire to scratch

-

02-12-2018, 11:26 AM #19Member

- Join Date

- Jan 2018

- Location

- kaiapoi

- Posts

- 7,437

SilencerTalk - Index page

This is the forum that I joined. 7 posts and haven't done one since I joined 3 1/2 years ago lol

from the land where you have to get a federal permit for a silencer the same as a rifle. It is issued to that silencer. Definitely not allowed to make your own willy nilly

-

02-12-2018, 12:52 PM #20

Yes, strange how the US is so awash with laws, including against silencers. Less "land of the free"; more home of the deaf. A moronic law.

I don't know what the actual stats are, how many murders get committed with suppressed guns vs with sharp/blunt objects, but I guess it does not matter. After all, it's plain from movies that killers for hire always use silenced guns...An itch ... is ... a desire to scratch

-

02-12-2018, 05:25 PM #21

I have one on my 357mag lever gun. Not sure who made it as it came with the gun and has no markings on it. Its a fairly sophisticated piece of kit.

-

02-12-2018, 11:14 PM #22

-

03-12-2018, 07:01 PM #23Member

- Join Date

- Jan 2016

- Location

- Omaru

- Posts

- 565

Sounds like a familiar design.... mine was 405mm long and 2" dia, it is pretty heavy though, if I get my mits on another barrel I might try for some slots near the muzzle end, or maybe just fluted with ports at the bottom of the flutes. The only tricky bit with your idea is getting the crown sorted depending on how deep you counter bore it, maybe a brass rod that is a good fit for your hole with the end turned/filed/ground to the same angle as the drill bit and some valve grinding paste. Im not really convinced the baffles in mine do anything but I have a lot of relatively small ports

-

03-12-2018, 09:58 PM #24

Yes, prob with long counterbore is keeping it concentric with the bore, or the crown will not be at 90 degrees to the bore either. I think main thing is to counterbore to somewhere where there is good rifling (that is why this rifle is getting chopped), less important to have a beautiful looking crown. Some dude out there did experiments with simply hacksawing a new hunting rifle one inch at a time and shooting the rough end with only obvious burrs removed, no effect detected on accuracy. Anyway, if you use a drill with more of an angle on the cutting edges it's self centering.

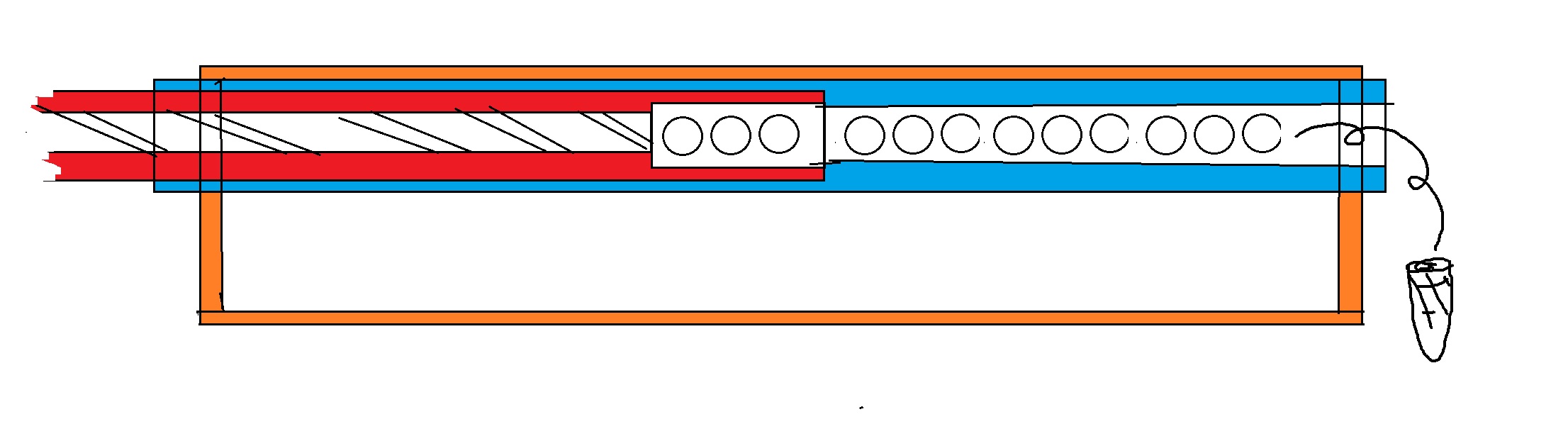

I have an alternative idea taken from overbarrel silencers, where a barrel protector sleeve is often added. You can extend that sleeve forward of the muzzle right to/through the front of the silencer and perforate it to your heart's content. A small barrel counterbore of 2 inches can still be done, with side venting ports, and the sleeve can be perforated over those ports. Baffles can be welded to the sleeve if desired.

Both solutions seek to address @gundoc's stated/hated no. 1 problem with eccentric suppressors - alignment.

Last edited by Cordite; 03-12-2018 at 10:22 PM.

An itch ... is ... a desire to scratch

-

06-12-2018, 07:36 PM #25Member

- Join Date

- Jan 2016

- Location

- Omaru

- Posts

- 565

-

06-12-2018, 11:41 PM #26

Thanks, just revisited your .410 de lisle thread and saw your long 10mm drill construction.

Yes, think you're right about avoiding the complication of the barrel sleeve. If I index the front and back caps to the outer sleeve I may be able to hold it all together simply with a thread at the end of the barrel. Some de Lisles have a short bit of barrel sticking out front of the silencer and that could be the treaded bit holding a screw-on retaining cap. Sleeve and baffles can be added at will later but the design will work to a degree without such.An itch ... is ... a desire to scratch

Similar Threads

-

Rifle barrel to australia

By akaroa1 in forum Firearms, Optics and AccessoriesReplies: 3Last Post: 29-12-2015, 09:32 AM -

over barrel suppressors

By longrange308 in forum Firearms, Optics and AccessoriesReplies: 13Last Post: 06-07-2012, 11:38 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

19Likes

19Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks