Some years ago I restocked my Martini 12/15.

I made my own Martini stock (from Red Beech), plus I had to figure out about drilling that long hole through it.

Here's my solution, and I hope it helps some of you or gives you an idea or two.

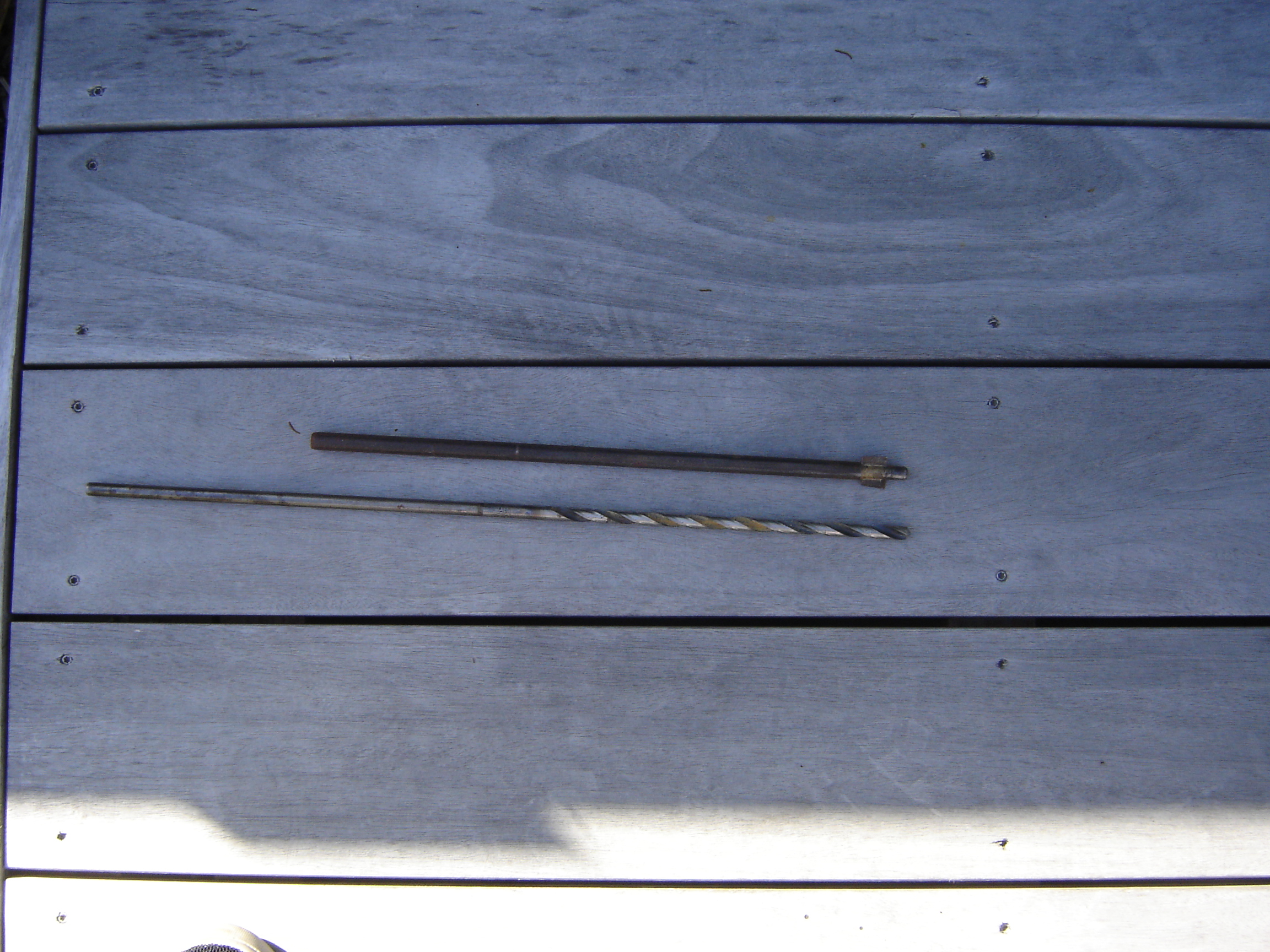

Part 1. Firstly I mounted a 5/16" drill (point first) into a lathe tailstock chuck.

Then mounted a 9" length of 5/16" rod into the lathe chuck.

Slid the tailstock along until both rod and drill ends were touching, then just heated the joint and bronze welded it.

If no lathe available then a length of angle iron that you sit both rod and drill into the groove. That should hold everything straight and level enough for the intended job.

Finish welding/smoothing and part 1 is done.

Part 2. The Wide Drill.

Next I took a 14" length of 1/2" steel rod, and turned the first 1" down to that drill size of 5/16".

Made up 2 little 'blades' from mild steel (completely adequate as no high speed drilling intended).

Bronze welded on the blades and then hand filed the cutting edges.

I think the photos show what I did. You just need to make the blade's cutting edge wider than at the back of the blade so that as you drill you have clearance for the rest of the blade to follow through.

No complex angles, or anything approaching 'rocket science'. Just as long as when the blades are welded on you file the outer edges down evenly so that the drill is not lop sided. My Wide Drill is 3/4" width, and this suits the Martini stock bolt. I made my blades 5/8" long but...your choice really for that bit. Near enough will do.

Part 3.

Line up by eye through your rough gunstock blank, and quietly drill the pilot hole with your 5/16" long drill bit.

Keep pulling the drill out as you drill to clear the drill lands or the drill may jamb.

Once the pilot hole is drilled follow up with the Wide Drill.

It is really a scraping cut but works OK in wood. The first wee 1" that you turned on the end will follow the hole already drilled.

Measure how long your original stock bolt is and you need to stop drilling the wide bit when you have enough length for that bolt to fit up nicely.

I then put the bolt down into the lovely new hole I had drilled and checked that I had made the Wide Hole deep enough to allow the proper length of bolt threads to show through.

Then started shaping the wee piece of wood that fits into the Martini action's rear stock 'socket'.

Once that was formed and finished I bolted the blank up fully to the action and started the shaping. I used a disc sander attachment on my hand drill, and taking care you can craft a nice shape. Mine has a palm swell too!

It really is not a hard job, just takes a bit of nouse to make the 2 drills needed, and don't drill the wide hole too far through (keep checking with the stock bolt and stop drilling once you have enough thread protruding through.

You don't need to worry about aligning the hole too much (if you have a rough blank). You will have plenty of wood to shave off to form your stock. You are forming your gunstock shape around the centre of the hole you drilled, which is way easier than having formed a lovely stock first and then try to drill the hole through.

I have put this description up on a USA site but some of you will never see it there, so thought it best to add it here too.

Or...if you don't want to make your own set...PM me and I'll do a deal for mine (dunno...$10 for both plus postage? Make me an offer I can't refuse?).

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 6 of 6

Threaded View

-

28-03-2022, 08:15 PM #1

Handy tools to make for 2 piece stock making.

Similar Threads

-

Making an a cat stock

By northdude in forum Firearms, Optics and AccessoriesReplies: 13Last Post: 22-01-2017, 03:12 PM -

thought i would make some tools

By stumpy in forum Projects and Home BuildsReplies: 7Last Post: 25-05-2014, 08:51 PM -

Help needed ... how to make your own stock ...

By tikka 7/08 in forum Projects and Home BuildsReplies: 39Last Post: 17-05-2013, 10:13 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

15Likes

15Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks