Been learning how to use a lathe, enjoying it a lot. Have made some custom cleaning jags with brass, a paper cartridge former out of nylon, and other bits and pieces.

So today I wanted to solve a problem with my Winchester 88 sights. I started with Skinner sight (https://www.nzhuntingandshooting.co....oration-97465/) but found that was too far forward for my liking so managed to track down an original Lyman Receiver sight for the Winchester 88.

Started with problem #1, Aperture is too small for my liking. All good for target shooting but no good for hunting. Also found the insert too small in outside diameter I prefer a larger insert.

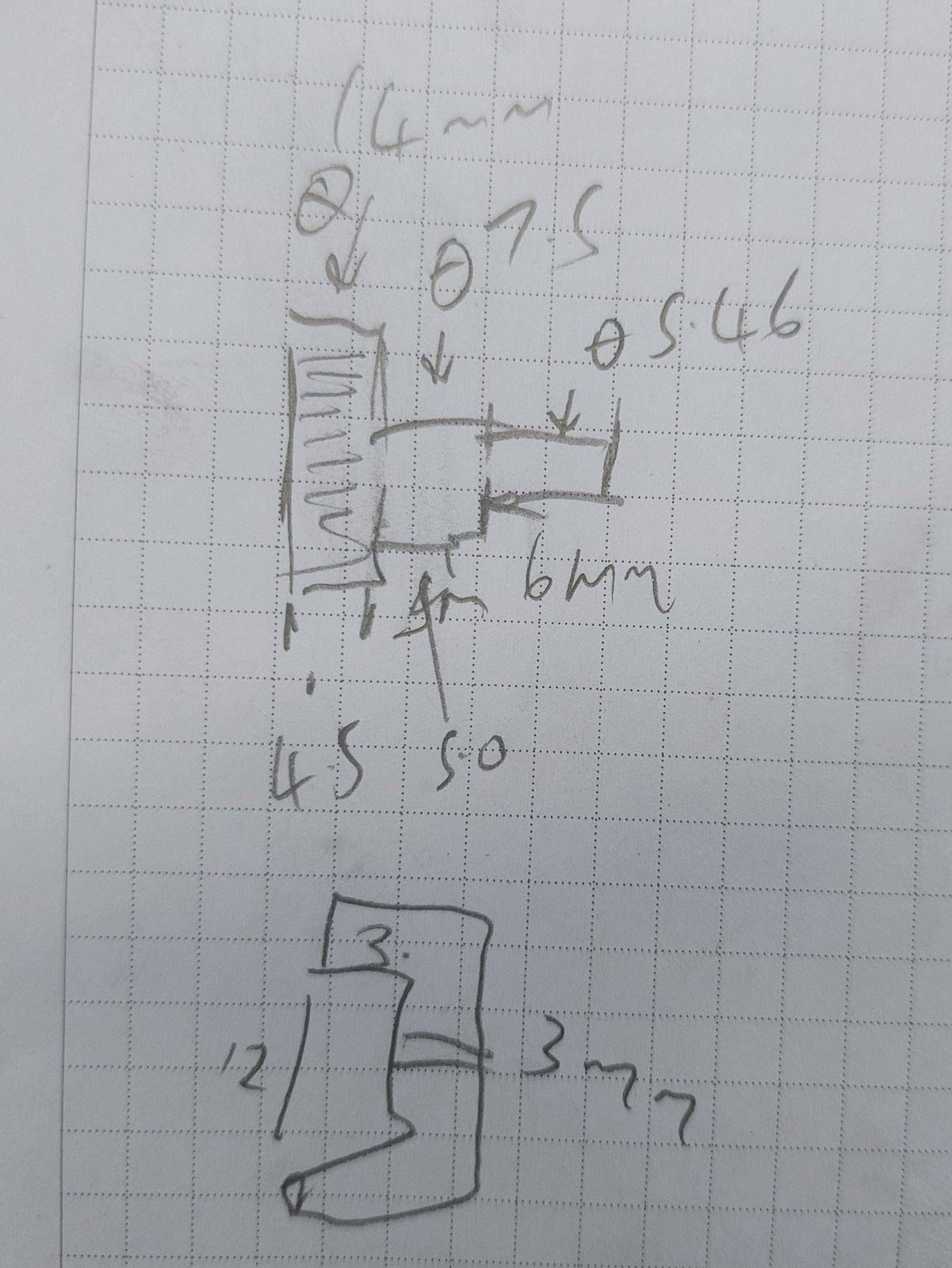

So I made another insert with a 3mm aperture and larger outside diameter. (Aperture size chosen as 1/8" being the suggested aperture size for general hunting). Realised a problem though, it cants up and bottoming out on the sight body.

Had to be very careful threading the insert as the 12-40 UNS thread doesn't take much to twist and bugger up. A very fine thread pitch.

Problem #2. This is the insert that come with the sight. While I made the new insert to the spec of this insert. I'm not sure the aperture that came with the sight is for this sight, it stops on the sight body and cants the whole aperture up. It needs a shoulder to register against the threaded portion of the sight.

Solution:

A quick oil blue:

Happy as, was a fun lathe project to learn a few techniques on. Including grinding a boring bit with good clearance for the face of the aperture. Even dived into the dark art of knurling, I'm not sure why the two attempts of knurling come out entirely different...

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 6 of 6

Hybrid View

-

01-01-2024, 07:47 PM #1Member

- Join Date

- Dec 2011

- Location

- Te Awamutu

- Posts

- 1,054

Layman receiver sight aperautre insert

Last edited by Makros; 01-01-2024 at 07:56 PM.

-

01-01-2024, 08:18 PM #2Member

- Join Date

- Dec 2011

- Location

- Te Awamutu

- Posts

- 1,054

Hilariously bad spelling in the title... I apologise...

-

02-01-2024, 12:34 AM #3Member

- Join Date

- Jun 2022

- Location

- Papakura

- Posts

- 1,613

Nice work, it's a huge rabbit hole when you start machining bits for your own rifle.

If you're getting inconsistent results when knurling try winding a little preload pressure between the knurling wheel and the part.

-

02-01-2024, 12:38 AM #4Member

- Join Date

- Jul 2021

- Location

- Whangarei

- Posts

- 503

Nice job, well done !

-

02-01-2024, 08:22 PM #5Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,954

A lot of that is also differences in sections off the same bar stock, I've noticed some where even though it's centreless ground shaft there are distinct variations in surface hardness. Don't get me started on chrome plated rod! All over the place...

-

04-01-2024, 10:31 PM #6

Looks great. My lathe would be the very last tool I would part with.

It's very satisfying making bits for your rifles and reloading tools.

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

6Likes

6Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks