Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 18 of 18

Thread: Looking for a smart bugger

-

29-12-2024, 06:36 PM #16"Does the brain control you or are you controlling the brain? I don't know if I'm in charge of mine." - Karl Pilkington

-

-

30-12-2024, 08:48 PM #17Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 6,179

I would be looking at either a laser cut service (don't know of any in NZ at the moment) or a heated but very thin core cutter that moves through on a press so it's a vertical cut. A card template with the holes cut in it in the right places would act as the guide. You could even print it out on paper, glue it to a thin piece of plastic or ply and cut the guide out that way. Once you have the guide set up stick it to the foam and press away. The high density foam is not cheap in the thickness you are needing for this, and it doesn't really freeze well enough even at -4 to make rotary cutters an option for my experience. Maybe if you had liquid nitrogen on hand, but in the freezer won't do cold enough to last for the length of time you'd need to drill out that many holes.

It isn't that hard to make a cutter tip to do this, you do need the stiff ni-chrome wire or the stiffer ribbon to fashion the cutter out of and this can be a little pesky to come by. Once you have the wire, bend up a two-row coil on the bottom with two legs going up to where you need to connect the power to make it hot. When the cutter goes through, you find a balance point in rate of push through the foam where you are getting a good melted cut without cooling the cutter too much and not melting to much. Once the cutter is withdrawn you need a little punch of some sort to push the offcut out. Then onto the next hole pretty quick so the cutter head doesn't get too hot... Control of the cutter heat is a factor of resistance, commercial setups have a resistor on a control knob that does this.

I've made up a heated wire cutter for this sort of foam and the pelican case type foam to cut out tool profiles and the like, it's hand guided so not that straight but apart from the up and down and the size of the hot wire (this is under tension to keep it straight so the fine stuff is OK) the concepts are the same.

-

30-12-2024, 10:29 PM #18Member

- Join Date

- Jun 2022

- Location

- Papakura

- Posts

- 1,657

Hi @nzfubz

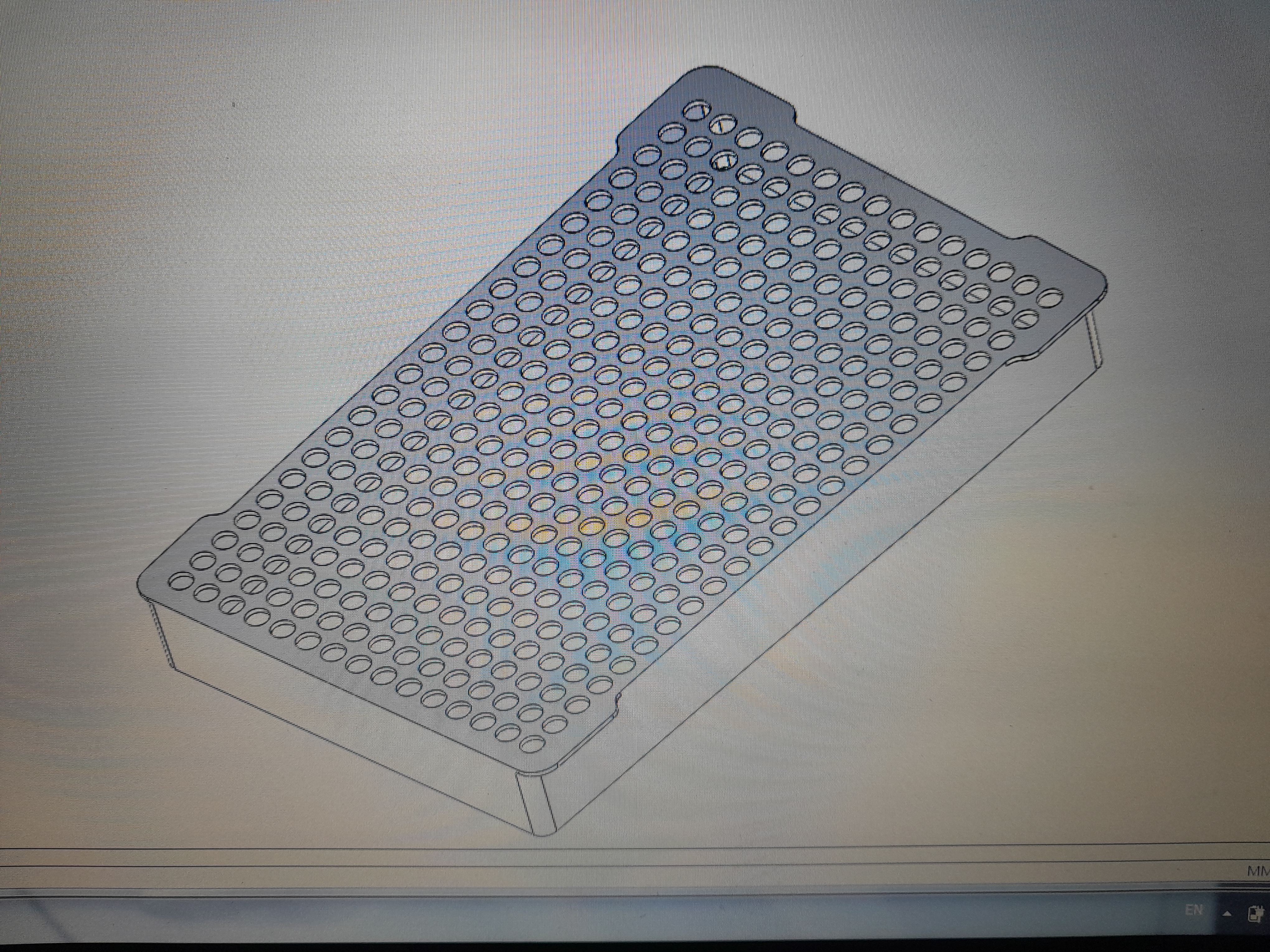

I don't have access to the workshop anymore but I'm happy to model up whatever you need. I think 3D printed would be better than foam but this company would be able to watercut it for you.

https://www.laserstream.co.nz/home

Here's a Pic of what a single layer printed one would look like.

Similar Threads

-

ATN LTV 3-9x Smart Scope

By AMac in forum Firearms, Optics and AccessoriesReplies: 4Last Post: 29-09-2024, 08:46 PM -

Smart Watches

By cambo in forum Gear and EquipmentReplies: 7Last Post: 23-07-2021, 08:48 PM -

BUGGER BUGGR BUGGER

By 57jl in forum Reloading and BallisticsReplies: 5Last Post: 11-09-2019, 06:36 PM -

Any smart ones out there?

By Boar Freak in forum Projects and Home BuildsReplies: 5Last Post: 06-08-2015, 09:48 PM -

whos a smart boy then??

By kotuku in forum Projects and Home BuildsReplies: 10Last Post: 09-01-2015, 07:03 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks