Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 59

-

08-07-2014, 09:42 PM #16Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,378

Boom, cough,cough,cough

-

-

08-07-2014, 10:44 PM #17Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,378

There's a stock for one on trade me "Lloyd82" he wants $135.00

Boom, cough,cough,cough

-

09-07-2014, 11:40 AM #18

Attachment 26642 Here is a pic of where the breech block, (not mine) fits in the receiver, and seeing that I`m making it I don`t think a standard stock would fit, would like to make one of black walnut. This rifle will be basically black powder loads or smokles and a range rifle or a Sharps business rifle, I can only make a barrel 24/25" long on my lathe, and can give it a twist of 1-24" or 1-20", not shore which is best, long range shooting uses a 1-18" twist with a .500gr bullet, I will be using .300/.450gr to save my shoulder. Trying to sort out my pic`s, cheers, Homebrew.357.

-

09-07-2014, 01:14 PM #19

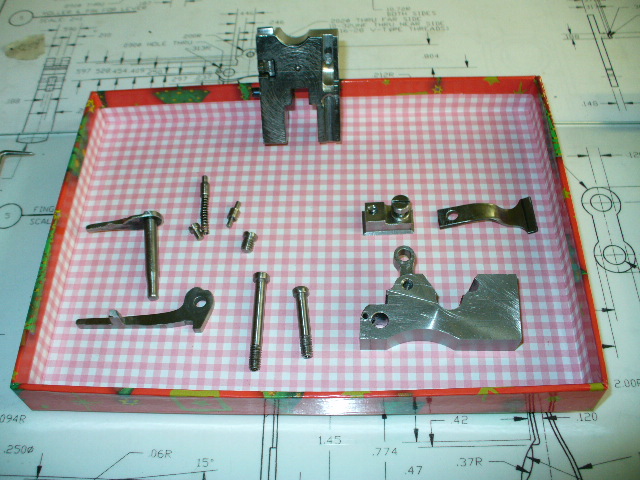

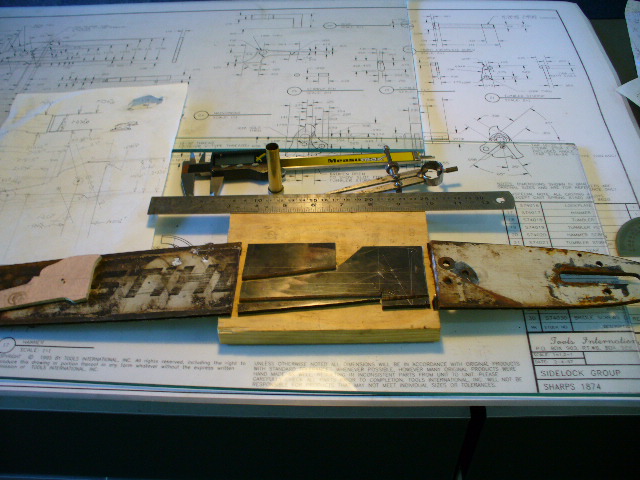

Some more pic`s to see if I can upload them, The lumpy bit at lower right is then of the breech under lever front bit, making it in tow bits, think I`v got it. homebrew.357.

Some more pic`s to see if I can upload them, The lumpy bit at lower right is then of the breech under lever front bit, making it in tow bits, think I`v got it. homebrew.357.

Last edited by homebrew.357; 09-07-2014 at 01:19 PM.

-

09-07-2014, 08:07 PM #20

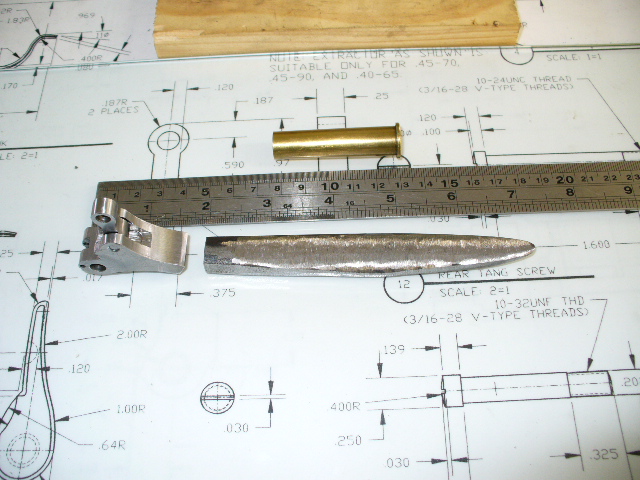

Ok, That lumpy bit part of the under lever/trigger garde , had to make it in two pieces and when both were ready I weald them together, then a lot of grinding, bending, sanding, polishing for a nice finish.

The Sharps 45-70 has a bore size of .458cal, the gun drill I had for my Hawken drilled a bore of .419/20, to much reaming to get the right size. So went on to Ebay in the US and bought one, 48" long x .444" dia. Now they drill a hole a bit bigger than there size, should come out to .445", leaving .013", so no reaming, just a polish with 600grt paper and cut the rifling .065 per side for a bore of .458", way to go!

Pic`s of the leaver, new gun drill and barrel to be, Homebrew.357.

-

09-07-2014, 08:17 PM #21OPCz

- Join Date

- Jun 2012

- Location

- Nor West of Auckland on the true right of the Kaipara River

- Posts

- 34,648

The work you are doing on this is frigging amazing.

It takes 43 muscle's to frown and 17 to smile, but only 3 for proper trigger pull.

What more do we need? If we are above ground and breathing the rest is up to us!

Rule 1: Treat every firearm as loaded

Rule 2: Always point firearms in a safe direction

Rule 3: Load a firearm only when ready to fire

Rule 4: Identify your target beyond all doubt

Rule 5: Check your firing zone

Rule 6: Store firearms and ammunition safely

Rule 7: Avoid alcohol and drugs when handling firearms

-

09-07-2014, 08:33 PM #22

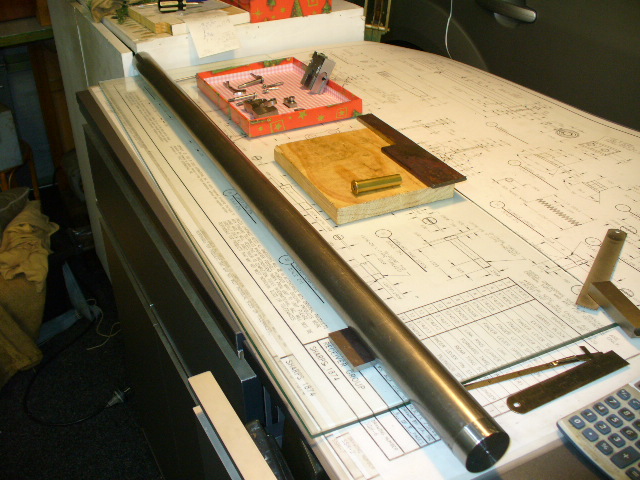

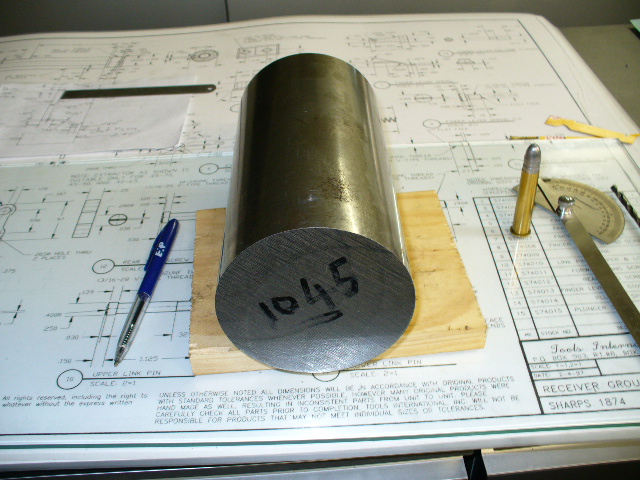

Here`s the new gun drill and barrel to be. the large round bit of aisi 1045 steel is going to be the receiver with a hell of a lot of machining!, O for a milling machine or c n c, good things take time.

Homebrew.357.

-

09-07-2014, 10:40 PM #23Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,378

Keep it going! I shoot 500 grain with 63 grains of FFG and my shoulder is just fine, that off hand, prone hurts real bad if you get it wrong!

Boom, cough,cough,cough

Boom, cough,cough,cough

-

09-07-2014, 11:04 PM #24

-

10-07-2014, 08:09 PM #25

Hi, Hey Maca is your one a Shilo sharps, with a 1-18" twist, it will shoot out to 800/1,000, like Billy Dixson. I`m thinking of 1-20" or 1-"24, should be good to 3/400 yards and a lighter bullet?.

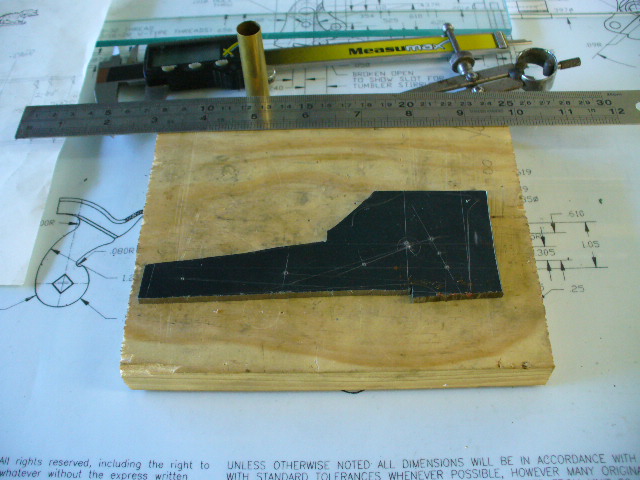

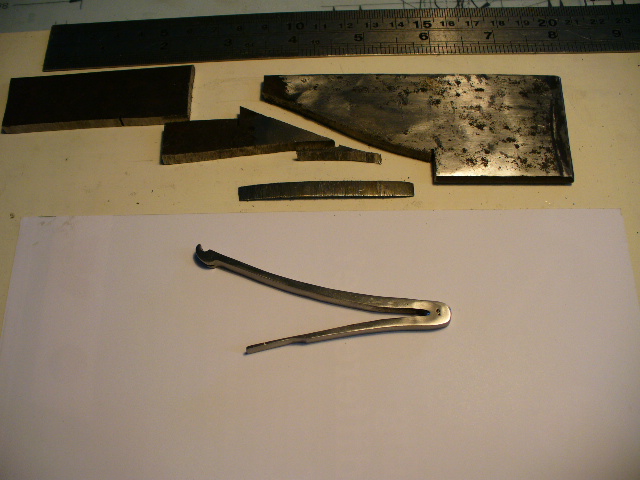

Making the side plate it has to be good hard steel, and you have to by a meter of it and I only need a small bit. So asking my son if he had any comeinhandy bits of good hard steel , yep, you can have my buggered up chain saw blade. It was so hard had to cut it with my angle grinder to get a small bit, then heated it to red hot and let it cool, now I could work it, and just the right thickness and when finished can reharden and temper to a good colour. And the same for the main spring assy, my idea is to make a spring out of a spring, so a soft bit of car spring steel was used to make the main spring and when finished just reharden and temper. some pic`s, Cheers, Homebrew.357.

some pic`s, Cheers, Homebrew.357.

-

10-07-2014, 09:59 PM #26Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,378

Your an inventive bugger, why a stihl and not a husky? Should it not be an American Chainsaw? Homelite or Poulan ! Hahahahahahahahaha

Boom, cough,cough,cough

-

10-07-2014, 10:58 PM #27

-

11-07-2014, 07:19 AM #28Member

- Join Date

- Nov 2013

- Location

- Normally Auckland for work, temporarily deployed to UK, St Arnaud on leave

- Posts

- 117

This guys youtube channel might be of interest to you as well - https://www.youtube.com/watch?v=xmV7H3qOPNI

-

11-07-2014, 09:18 AM #29

Brilliant Homebrew, you are a true machinist, good luck on your project.....

While I might not be as good as I once was, Im as good once as I ever was!

Rule 4: Identify your target beyond all doubt

-

11-07-2014, 08:38 PM #30

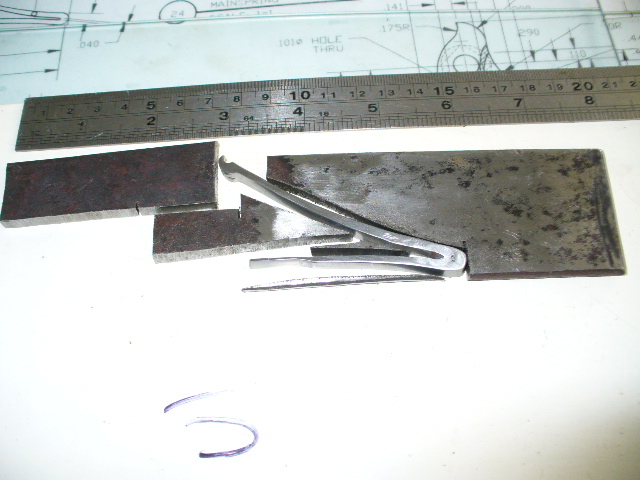

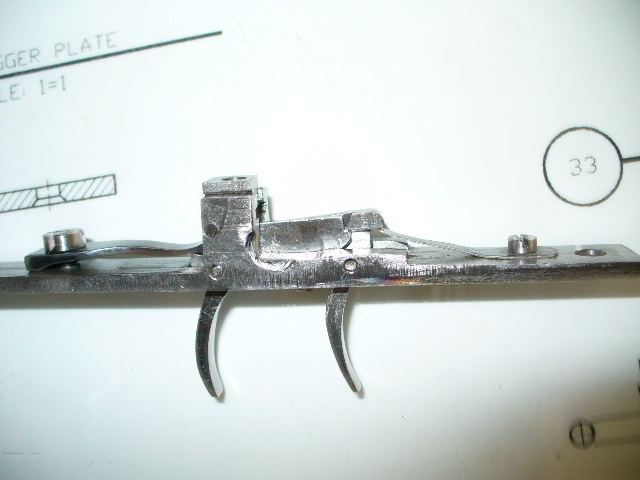

But wait there`s more!, I also used car spring for the set triggers, they need to be hard as well, with lots of milling, grinding and polishing , made the set spring as well and a bit of a test ,all is working good .

Scouser, No I`m not a machinist, that's not fair to the guys how have done there time in the trade, I just muddle along and hope it comes out right . Yes I`m building it good and strong, that is until I give it a good stiff proof load !

. Yes I`m building it good and strong, that is until I give it a good stiff proof load ! , some pic`s before I blow it up, Homebrew.357.

, some pic`s before I blow it up, Homebrew.357.

Similar Threads

-

Legend in the making

By Pengy in forum FishingReplies: 2Last Post: 12-03-2014, 08:46 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

100Likes

100Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote There's just no substitute for good quality

There's just no substitute for good quality

Bookmarks