Like the depth gauge on your tailstock, very clever

I have something similar on my mill quill, but should do the same for my lathe.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 106

-

26-04-2020, 08:14 PM #31Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

-

26-04-2020, 09:55 PM #32

What, that flaming thing, I`ve never used it ,had one for the lathe slide as well and would have been more accurate using a rubber band, once oil gets in it`s stuffed. I like my rubber Vernier, you can stretch things a bit if they are short..

-

27-04-2020, 08:24 PM #33

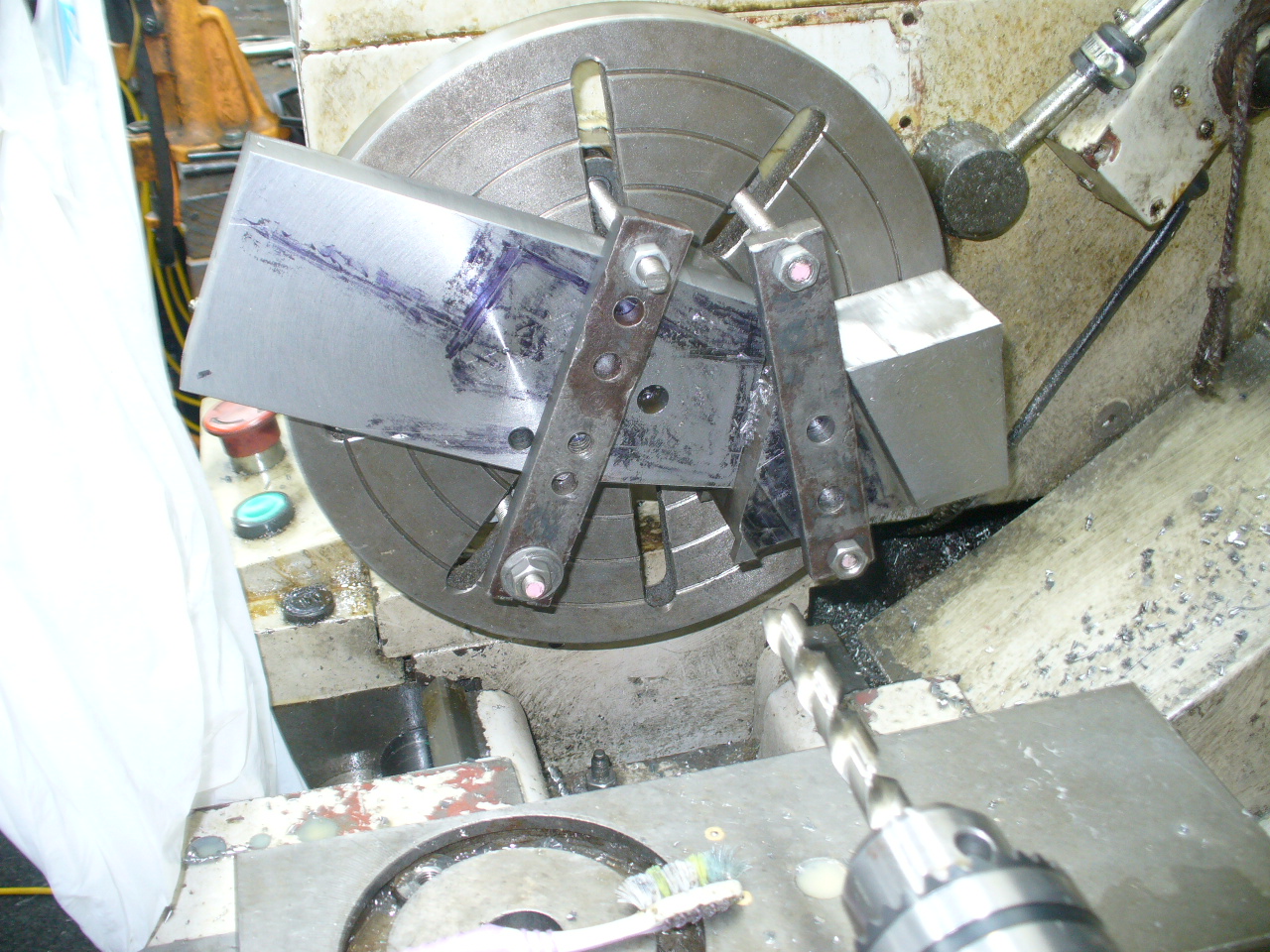

It`s always hard to figure out what to do next, but as I had marked and pined the two roller pin holes I thought mite as well drill them out. So fished out the face plate and setup the lump of steel on datum for number one hole, this is for the breech block and will finish it to the right size of .454" .

, First hole.

, First hole.

-

27-04-2020, 08:32 PM #34Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,834

@homebrew.357 just a though

But wouldn't it be interesting to have weighed the block of steel when you started and weigh the bare action when you are finished and see what percentage you ended up with

-

27-04-2020, 08:36 PM #35Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,834

I did some serious stock reduction today to knock a 32mm diameter round bar into a 15mm square bar.

Relatively easy with the power feed.

I was able to run the mill in the feed and be working on the lathe at the same time.

Swarf everywhere

-

28-04-2020, 11:53 AM #36

Could be, but a bit late now and maybe it would be better if I weighed myself and see how much more has been added . Your rubbing it in with that humugus flaming milling machine, I`m getting a lotto ticket,

. Anyway I just realised my .45 barrel reamer comes out at .4505", so will be good to ream out the holes and just leave a bit to bore out to size, getting there.

. Anyway I just realised my .45 barrel reamer comes out at .4505", so will be good to ream out the holes and just leave a bit to bore out to size, getting there.

-

28-04-2020, 12:01 PM #37northdudeGuest

probably a dumb question but why do you drill it in the lathe and not in a drill press

-

28-04-2020, 03:51 PM #38Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,834

-

28-04-2020, 07:50 PM #39

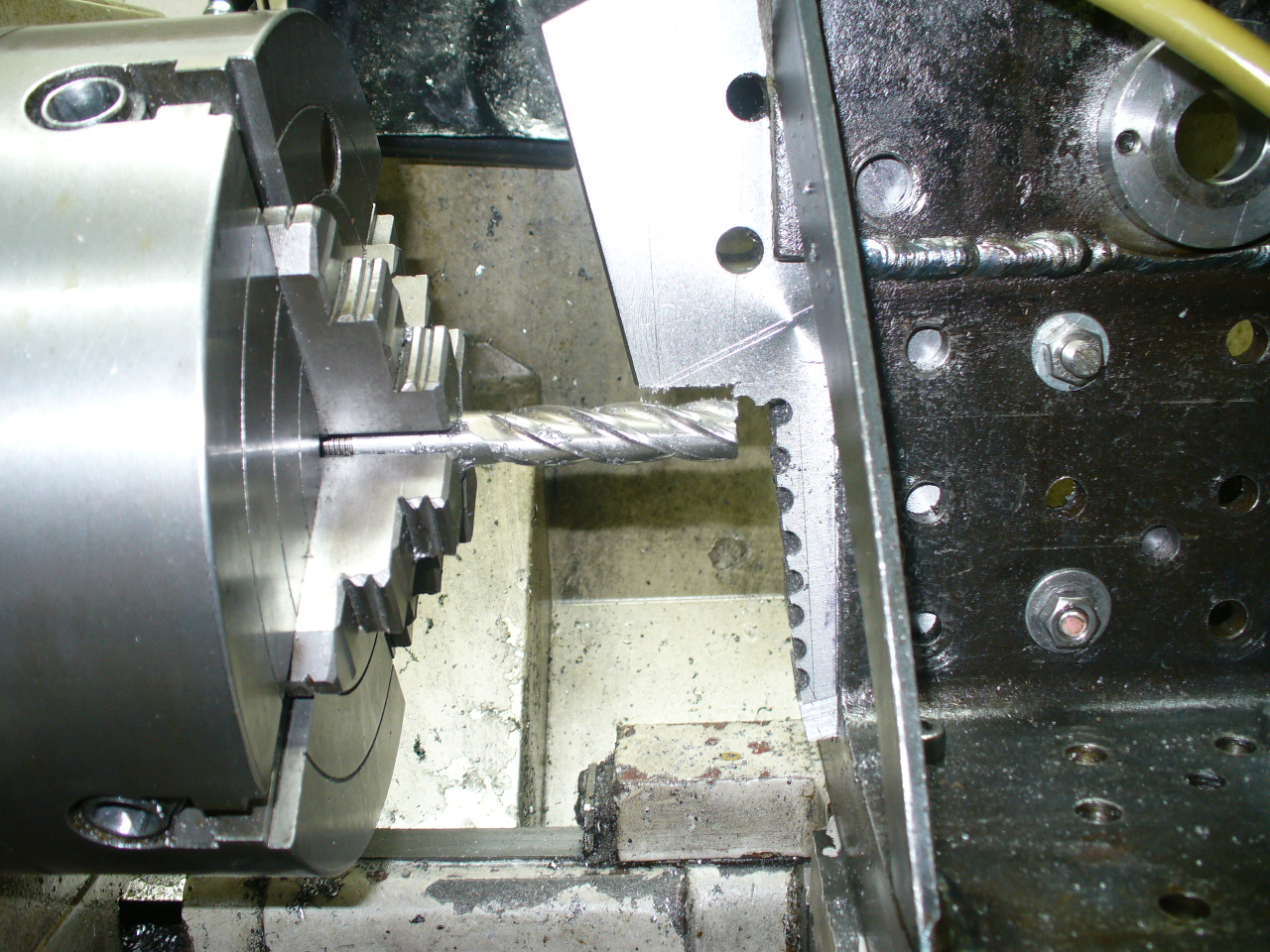

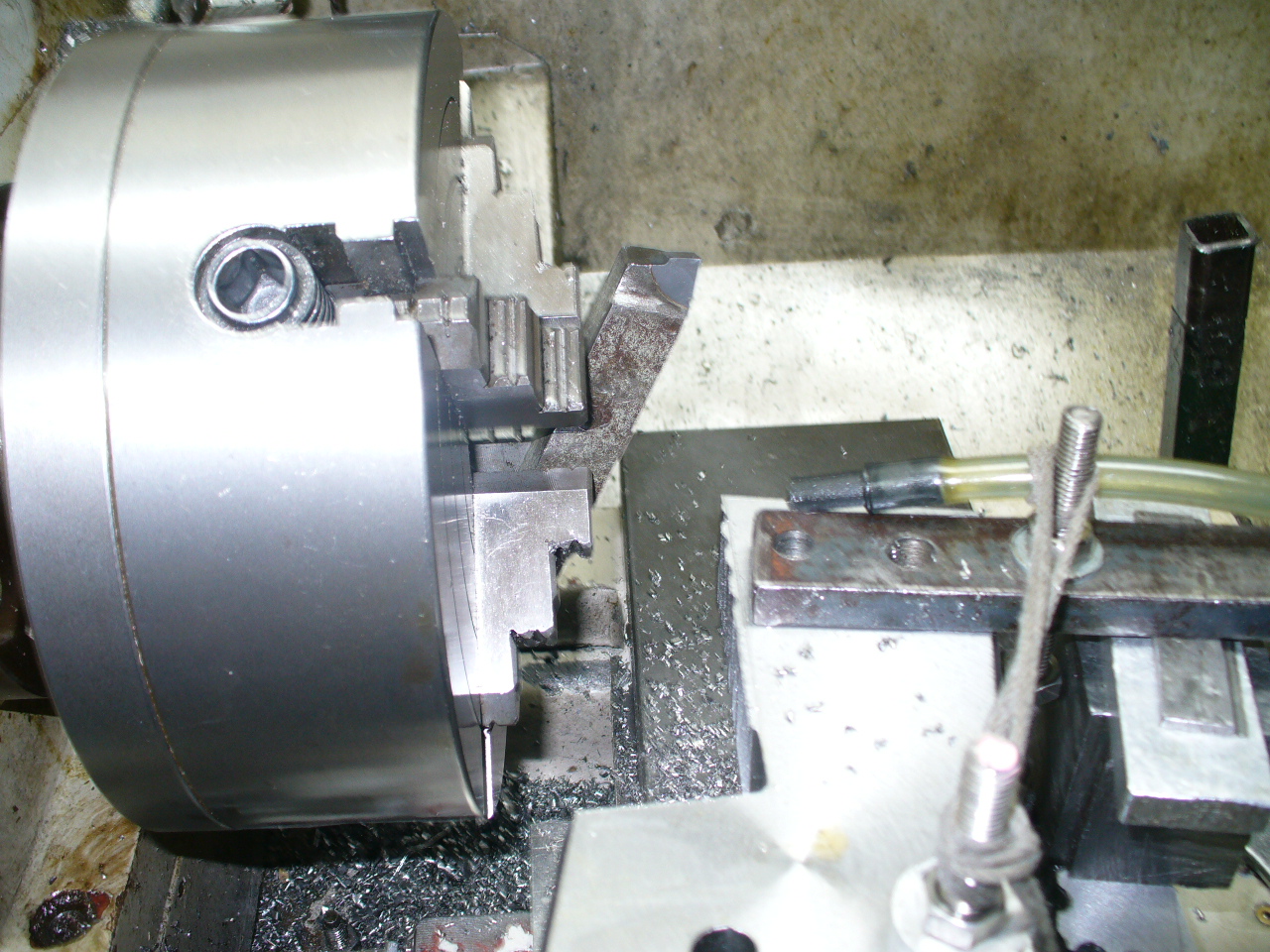

I like using the lathe for everything, it`s just more accurate than the drill press which can wander out of line and the pin holes need to be true and smooth so the last bit was a boring bar for final cut. The pin holes are the same size as the breech and hammer pins on the plans, are they a press fit in the action, I thought a sliding fit for removal to clean the rifle. My idea was to rough up the pins, then grind to final size for a fine finish and slip fit in the action.

, T/C tipped boring bar for final sizing of the two holes.

, T/C tipped boring bar for final sizing of the two holes.

-

29-04-2020, 08:34 PM #40

No I`m wrong, the pins are press fit in the action, watched a Midway bit on stripping down a roller and the pins are taped out. So pins to action are size for size .454" and the holes in the breech and hammer are .455". Had to cut a lump off my lump so I used the swiss chees technique, that means a row of holes along where you want to cut, makes cutting a lot easer but still had to setup for milling it my scratch line come datum point, it`s getting there.

, You wont see this very often .

, You wont see this very often .

-

30-04-2020, 08:57 PM #41

Well looks like you are seeing it again but its the other side, this is the under side of the tang. Nothdude you will be happy to know I used the drill press for all the holes this time, It`s just that the action holes had to be spot on and square to the action, so use the lathe . Gremlins getting in, just about finished the milling that first bit when bang the milling bit snapped, bugger, but had a spare one so job done . Had a talk to Tub@steel as to where my two bits of 4140 was going to come, lost my order sort of stuff but it`s on the way, so may be looking at making a barrel to see if I can improve on them.

, Fly cutting it true.

, Fly cutting it true.

-

30-04-2020, 09:15 PM #42northdudeGuest

cool stuff ive never thought of using the lathe how you do i might have another look at the lathe at work and have an experiment

-

30-04-2020, 09:15 PM #43

This is why the lathe is called "the universal tool", if you have the time you can make almost anything on it.

An itch ... is ... a desire to scratch

-

30-04-2020, 11:00 PM #44Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,339

Darn tootin,! Back in the '60's a good mate of mine made an excellent copy of a .22 Colt Woodsman from an exploded view parts diagram and the entire job was done on a Myford ML7 with a milling slide accessory. He is a highly skilled toolmaker but he was still in his apprenticeship then. A basic machine combined with skill and patience can make just about anything.

-

01-05-2020, 08:47 AM #45Banned

- Join Date

- Mar 2016

- Location

- auckland

- Posts

- 2,453

Very cool. Do you need any special license to make these? What pressures will it run at/to?

My dad is a soon to be retiring fitter/turner who makes can't find vintage car parts in his spare time. I could put him and his mates onto one of these.

Similar Threads

-

Making a Sharps Barrel in my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 273Last Post: 08-03-2021, 05:22 PM -

Rolling block

By rusl in forum Firearms, Optics and AccessoriesReplies: 26Last Post: 04-08-2019, 03:07 PM -

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

189Likes

189Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks