If you have a picture on your back you dont need a license to do anything and they seem fine with it

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 46 to 60 of 106

-

01-05-2020, 09:38 AM #46northdudeGuest

-

-

01-05-2020, 09:44 AM #47Banned

- Join Date

- Mar 2016

- Location

- auckland

- Posts

- 2,453

What does that mean?

-

01-05-2020, 10:15 AM #48

-

01-05-2020, 10:19 AM #49

You can make a firearm for yourself provided it is legal to have with your FAL. Like, don't make a pistol if you don't have B-cat license.

You can later pass this firearm to someone else, but you can't manufacture a firearm for someone else or with the intent of selling it, I think you need some sort of ticket for that, maybe @gundoc can fill in more details.

Of course with new arms regulations, my mate would not able to help me even put a scope on my rifle unless he is a licensed gunsmith...

EDIT: adding beginning of section 5 of the current arms act, my emphases in bold:

"5. Dealers to be licensed

(1) No person may, unless they hold a dealerís licence under this Act issued by a commissioned officer of the Police,ó

(a) in the way of business sell any firearm, prohibited magazine, prohibited part, airgun, pistol, or restricted weapon; or

(b) manufacture for sale any firearm, prohibited magazine, prohibited part, airgun, pistol, or restricted weapon."Last edited by Cordite; 01-05-2020 at 10:27 AM.

An itch ... is ... a desire to scratch

-

01-05-2020, 11:11 AM #50

Now that's it, a barrel is a tube with splines cut in the bore, what you do with it is up to you, good for watering the garden. If you asked me to make a action for you ,"NO WAY", I only make rifles for my own use and are proof tested, I gave my Sharps rifle a good test shooting with a hot load that would make a Ruger #1 sit up and take notice!!. So there`s no numbers or stamps on it. It`s ok to mill on a lathe, BUT, only light cuts, not like someone with a 2.200kg monster .

-

01-05-2020, 11:28 AM #51Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,341

Yes, you do need special permit/licence to make such things these days. Back in the 60's it was a highly illegal activity but a fascinating technical challenge. Proof that laws only work with those who choose to obey them. The pistol worked well on both standard velocity and high velocity ammo and, with the exception of pins and springs, was made from mild steel.

-

01-05-2020, 12:24 PM #52Banned

- Join Date

- Mar 2016

- Location

- auckland

- Posts

- 2,453

-

01-05-2020, 11:03 PM #53

@gundoc

Yes and if Iím not mistaken the same talented individual, once freehand cut on a milling machine the Jaguar script on the set of knock offs for his E Type Jag.

-

02-05-2020, 10:54 AM #54Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,341

-

02-05-2020, 11:58 AM #55

Im interested to see how you go about cutting the internal recesses. Its that operation that has stopped me from attempting a rolling block so far.

-

02-05-2020, 06:37 PM #56Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,184

brew me old china wheres me sporran mounted 25pounder comin off the production line .

It wll give a hole new meaning to the words "gettin a shot away"-specially on mallards!!

now given both of us have a penchant for home brewed ale -i always found i did better work and thought a lot more outta the box ,if I raided the fridge 1st and gazed intently at what i was working on whilst emptying a bottle or two!!

bloody amazing "rough as guts" manufacture but very effective .My warehouse jandals recoil pads was a love child of this approach.

gadgetman recently used the approach -though it looked prettier -lack of ale Id suspect!!

Keep up the good work!!

-

02-05-2020, 09:22 PM #57

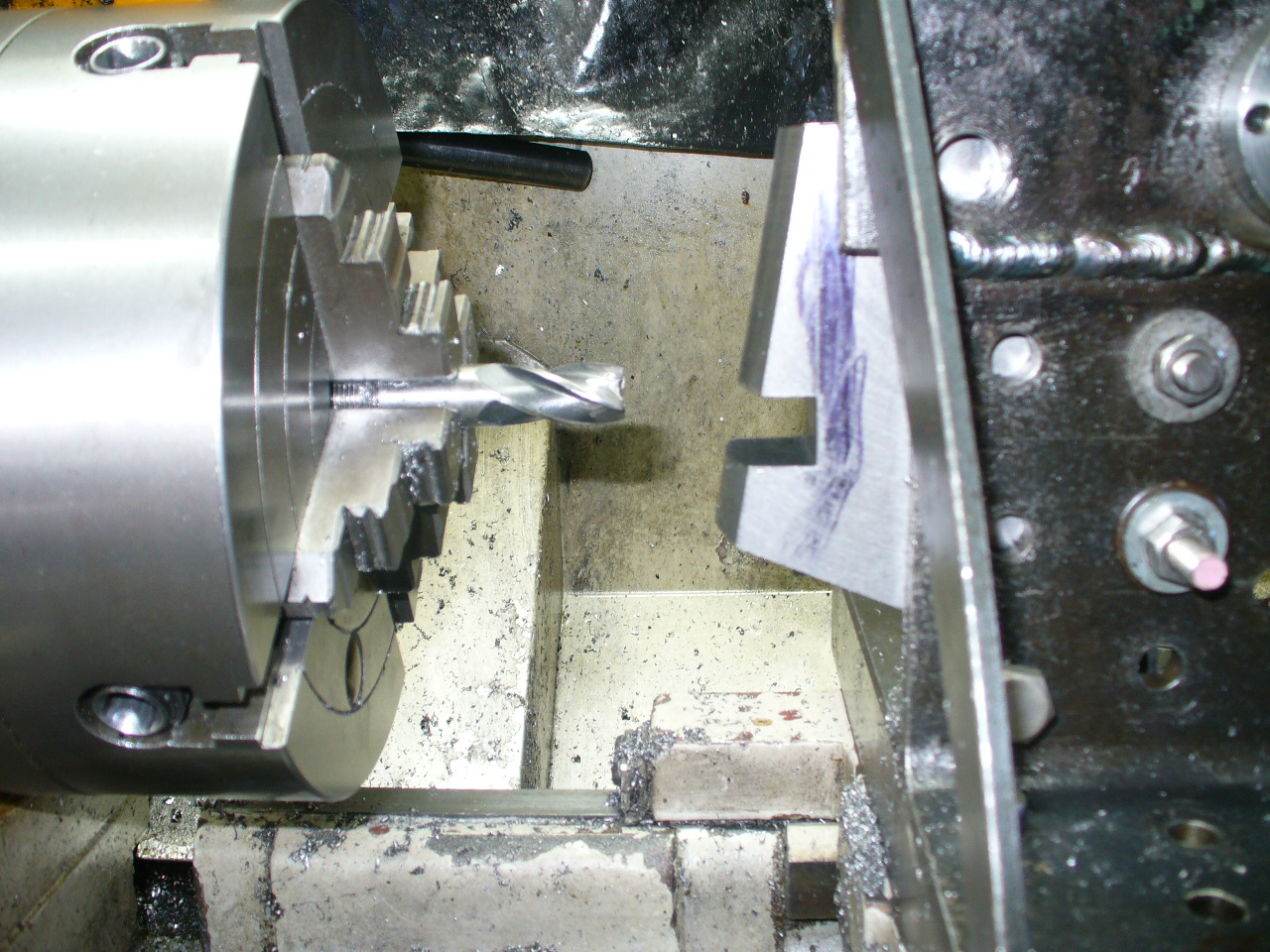

Hi you old bugger, lucky your brew`s not like mine, have to don the full antivirus suit AND wear a recoil pad before I open one of my 25lder bottles of brew, the gases explosion can be heard in wellington. Now the gas has cleared it I setup to mill a slot in the under side of the action so I could fly cut most of it off. The end bit is slightly curved so will do that last. And yes Tensixty that's some thing I have to work out. It`s getting there.

, Milling the slot so I can cut the rest.

, Milling the slot so I can cut the rest.

Fly cutting the rest.

Fly cutting the rest.

-

02-05-2020, 09:28 PM #58Member

- Join Date

- Jan 2019

- Location

- South Canterbury

- Posts

- 1,652

Awesome, I'm learning a lot of new tricks by looking at the way you achieve different things. I have a small mill at work but some of your techniques are inspiring.

-

02-05-2020, 11:13 PM #59Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,341

-

03-05-2020, 09:54 AM #60

My top slide has a bit of slop in it to, trying to think how you cut a acme thread to makeup a new worm nut. Always try a mill with the cutting force downwards and my lathe is always covered in swarf, cooling fluid, cutting oil and T68 lude oil, also some gun drilling oil when I get a leak at 400psi, the celling's not rusty ether. The lathe is sitting on carpet, in a steel tray, don`t want to stuff up the carpet.

Similar Threads

-

Making a Sharps Barrel in my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 273Last Post: 08-03-2021, 05:22 PM -

Rolling block

By rusl in forum Firearms, Optics and AccessoriesReplies: 26Last Post: 04-08-2019, 03:07 PM -

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

189Likes

189Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks