You will have to grind up a piece of HSS to the Acme thread shape (taking the dimensions off your top slide screw) making sure the depth of the tool will allow enough depth of cut. Make sure the tool is a few thou narrower than the crest of the screw thread. Because the Acme thread is tapered equally on both sides it is just a question of making cuts until your screw shaft is a snug fit. This will leave a small recess in the crest of the thread for crap to accumulate. You could lap the thread with the screw shaft and some Brasso for a perfect fit. When assembled adjust the gib strip to give a fairly firm fit which will help prevent sudden movement of the slide.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 61 to 75 of 106

-

03-05-2020, 11:39 AM #61Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,341

-

-

03-05-2020, 11:43 AM #62

well that instruction Gundoc is like me reading zulu.....but its plurry heartening to see you knowledgeable chaps shareing you lifetimes hard earned knowledge with each other so freely.

-

03-05-2020, 03:03 PM #63

Yer, just had a deko on UTUBE about it, looks doable and you cut the thread on a angle so cutters only cutting one side. Have finished the under milling and just needs the lug cut off then a radius that's just under the front of the action. It looks like to me that most of the inside is gutted out and only small sections left, under the barrel and back of the hammer, it`s getting there, have look at what I`ve got now from when I started, wish I could loss weight like that.

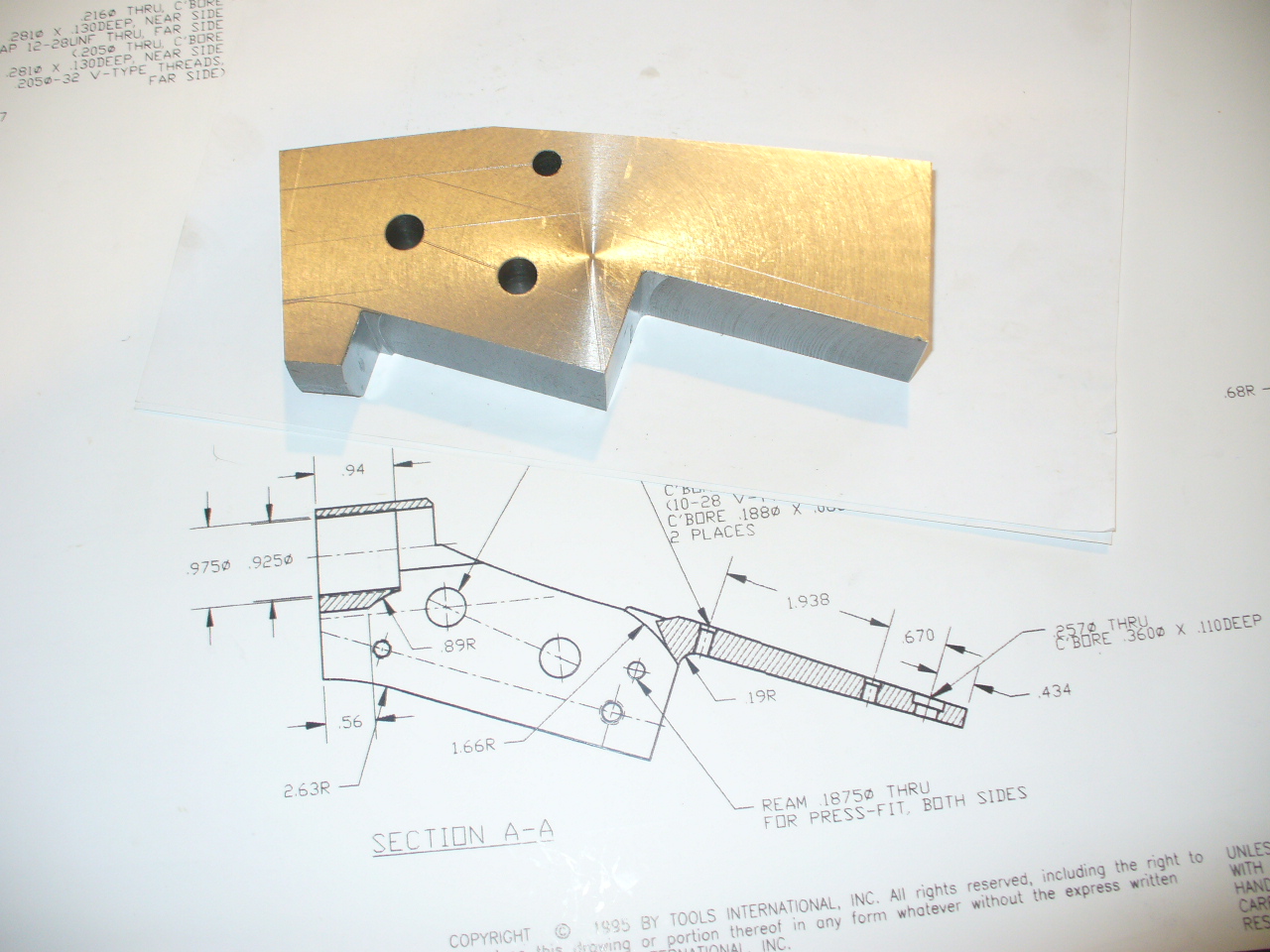

, Starting to look the part.

, Starting to look the part.

-

04-05-2020, 07:40 PM #64

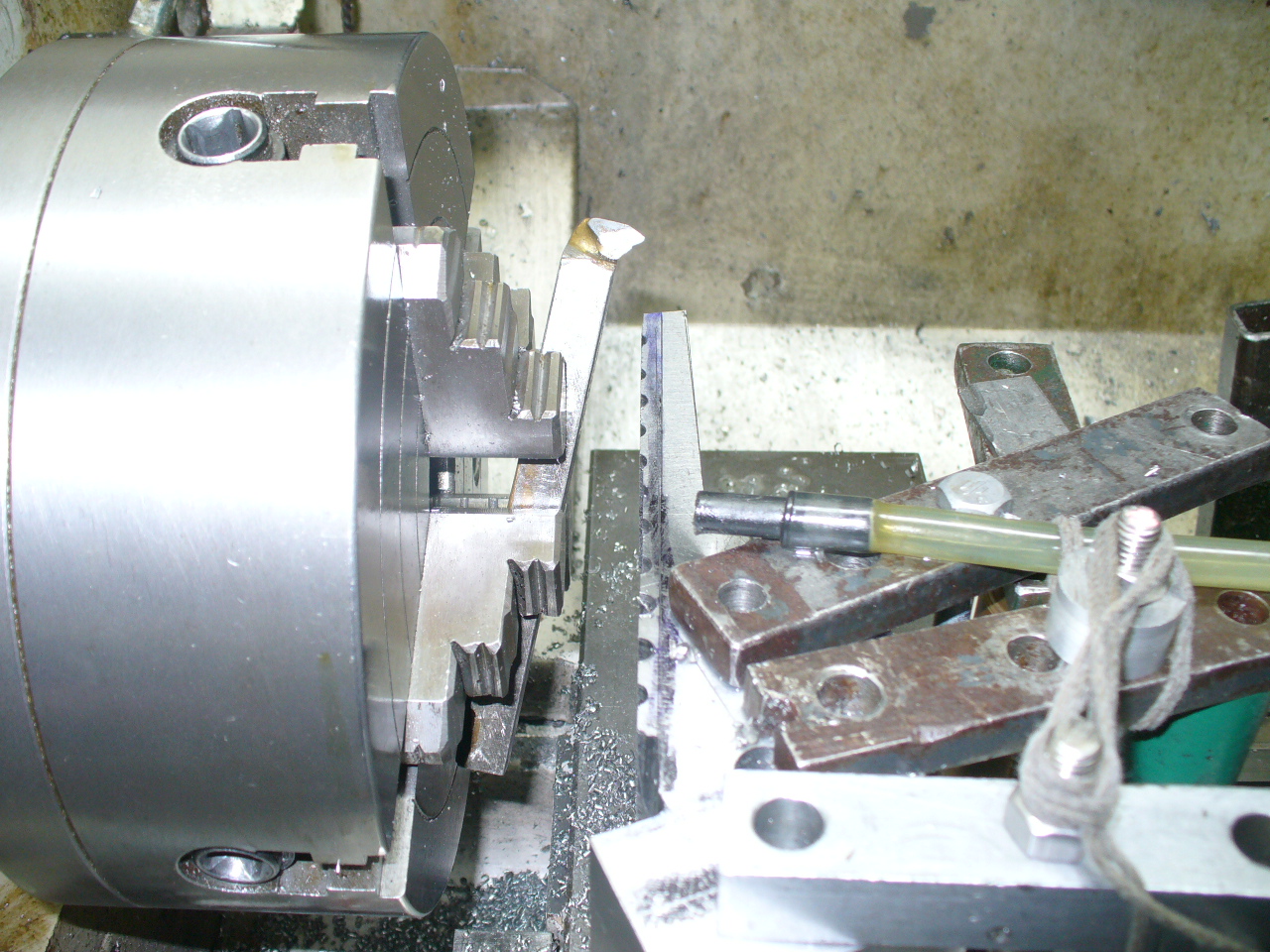

So just moving along there the lumpy bit has got the chop and have machined a sexy curve at the front so the bottom bits basically finished. So here`s some more learning bit`s Rumpy of how to make sexy curves on the lathe.

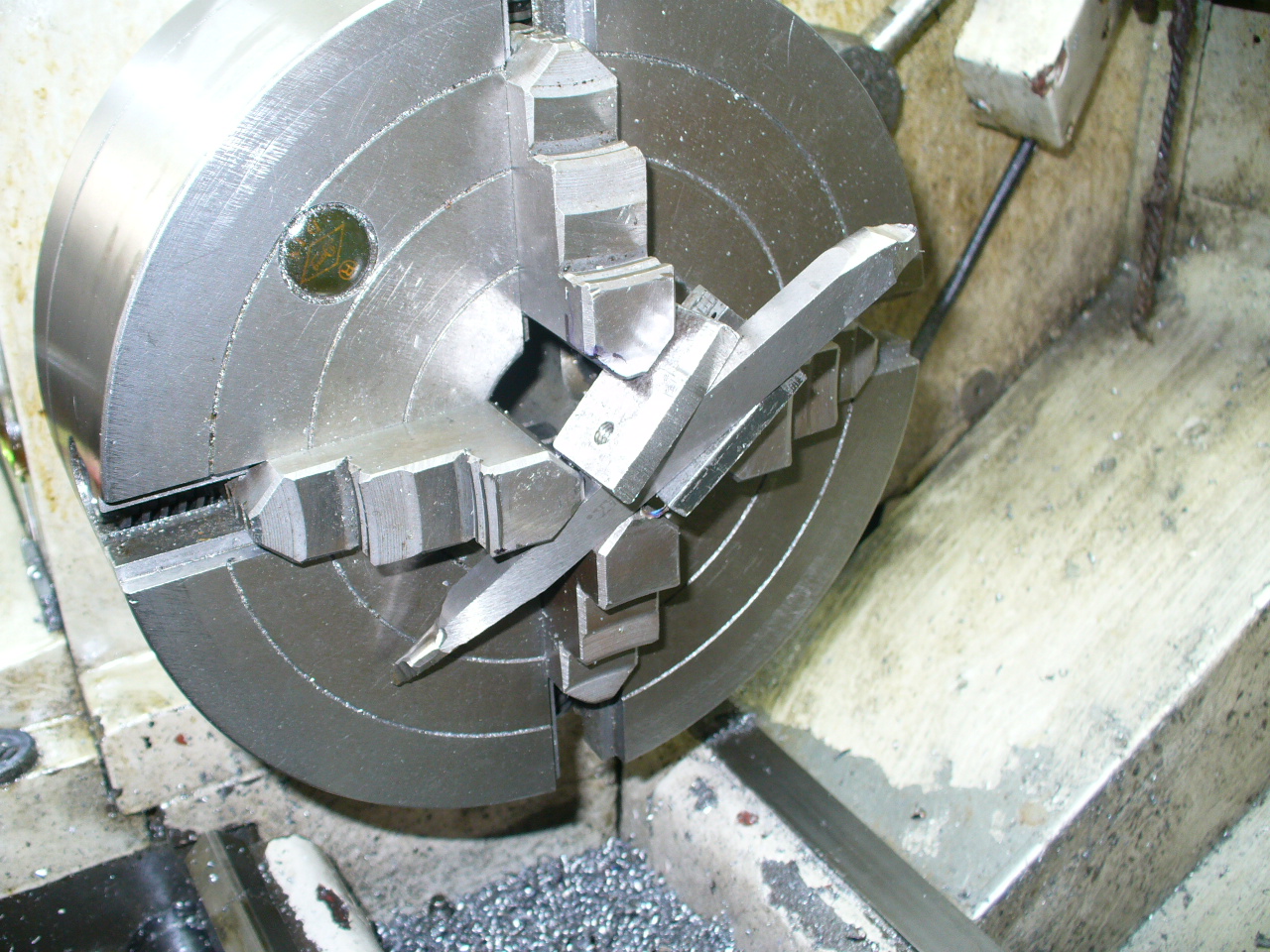

, the curvy bit.

, the curvy bit.

, Fly cutter in the chuck, easy peasy .

, Fly cutter in the chuck, easy peasy .

-

04-05-2020, 07:58 PM #65

Crack up system there, whatever works aye

Sent from my iPhone using Tapatalk

-

04-05-2020, 08:15 PM #66

Yer, you've got to think a bit and I`m always saying I haven't got a mill, all I need to do is turn the lathe up on it`s end and bingo I`ve got a mill.

-

04-05-2020, 10:45 PM #67Member

- Join Date

- May 2018

- Location

- Porirua

- Posts

- 1,342

I’m enjoying this @homebrew.357 thanks for the regular updates.

Remember the 7 “P”s; Pryor Preparation Prevents Piss Poor Performance.

Remember the 7 “P”s; Pryor Preparation Prevents Piss Poor Performance.

-

05-05-2020, 08:09 PM #68

Still witling it down and I love swiss chees and will keep you posted on progress, but it`s going to take a while. In the mean time I have just got my lengths of 4140 steel 1-1/4" round for barre making, so may have a rest of the roller for a bit, I`ve got lots to do.

, bit of cleaning up should see it right, now setting it up for milling the breech face, got to be spot on.

, bit of cleaning up should see it right, now setting it up for milling the breech face, got to be spot on.

-

05-05-2020, 08:45 PM #69

ok so...you using your lathe...a bit like a router????but fixed......taken me awhile to twig what you doing...THINK Ive got it now.

-

05-05-2020, 09:48 PM #70

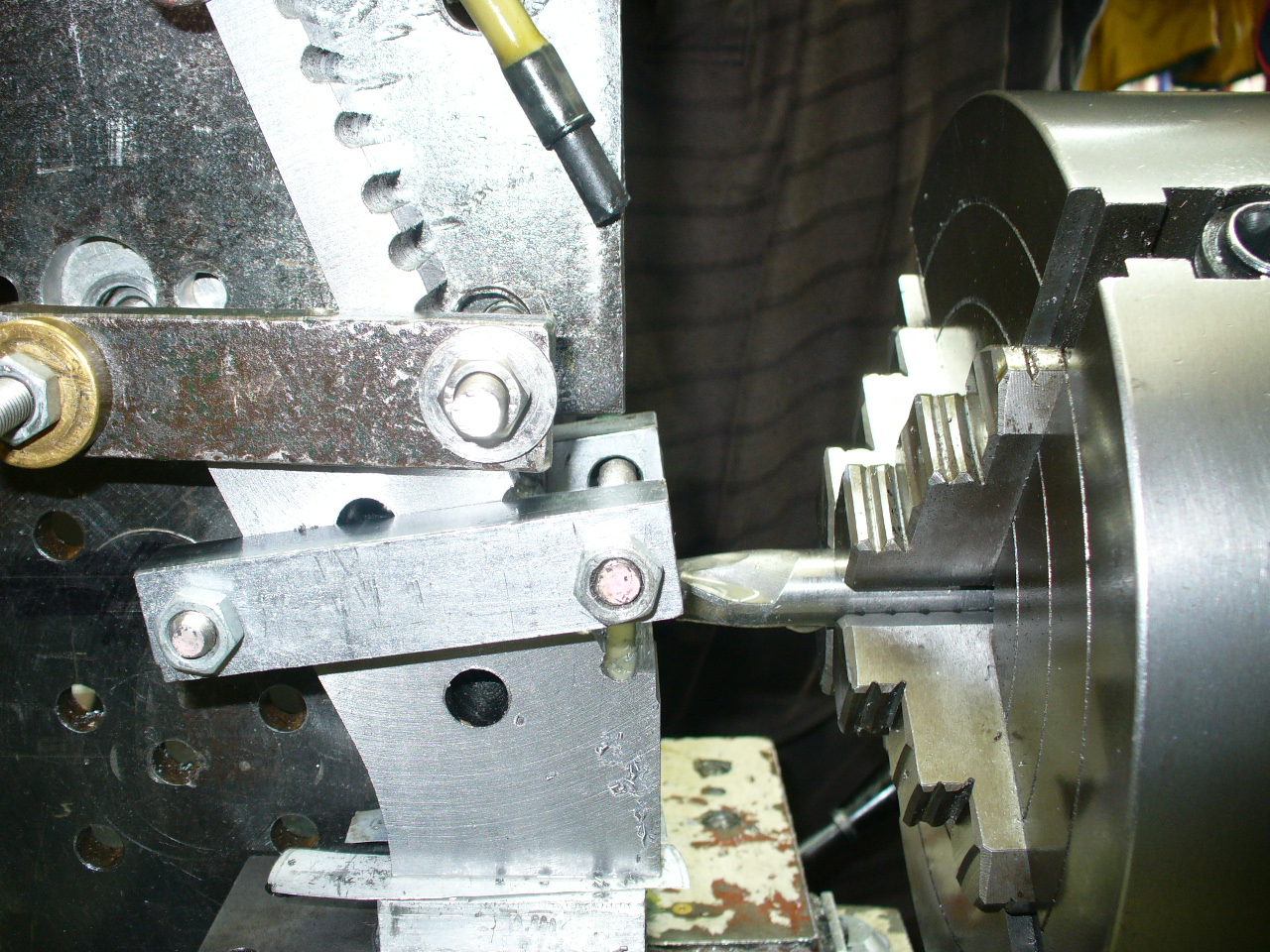

It`s hard to see there, but the action is packed away from the angle bracket and the fly cutter prescribes the ark of the curve I want to cut. It`s clamped on the cross slide so first cut is .010' on the infeed of the cross slide, with the saddle on feed towards the chuck and chuck turning it shaves of a bit till its gone in the full thickness of the action. the back up, in .015" and in again and keep doing this till the cut is where you want it.

, Zulu.

, Zulu.

-

05-05-2020, 09:50 PM #71

-

06-05-2020, 07:55 PM #72

Now look here Micky you are going to stop watching Shortland street for a bit, and get your head around the mechanical bits, a can opener is for tins, not removing primers. Look at this, setup to cut the face of action where the breach block is, it flicks up and holds the case in. This is were the barrel will eventually screw in to the action.

, The back of the setup.

, The back of the setup.

, front bit , you can see the milling cutter doing it`s bit.

, front bit , you can see the milling cutter doing it`s bit.

, this is where it`s at. See, just like putting on a gumboot.

, this is where it`s at. See, just like putting on a gumboot.

-

07-05-2020, 05:55 AM #73Member

- Join Date

- May 2016

- Location

- carterton

- Posts

- 1,048

whish i could put on gummies like you do

-

07-05-2020, 07:29 PM #74

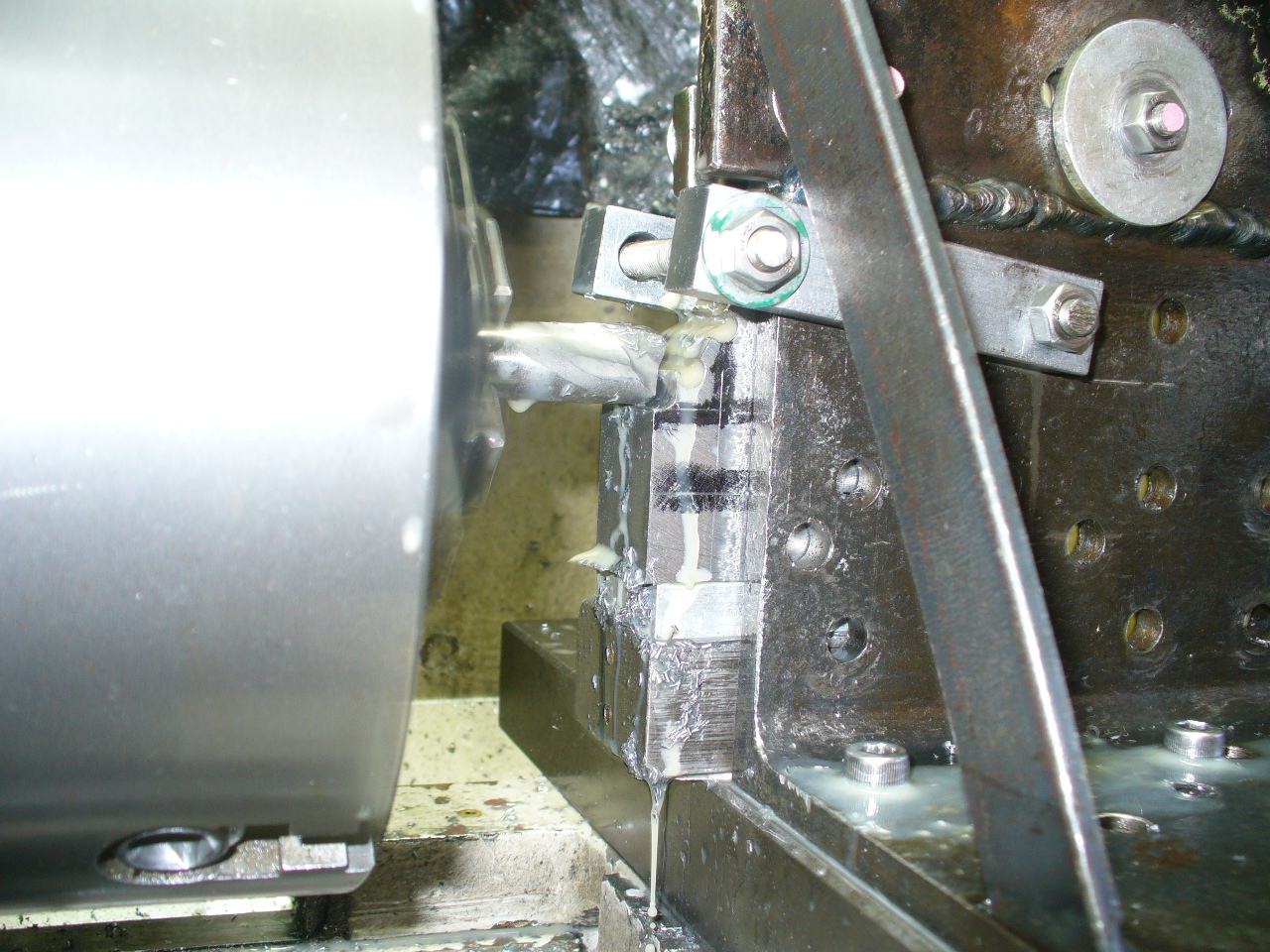

Had our first bit of hail a shower so getting nipper, had to stoke up the fire, so on with the gummies for a load of fire wood. So while I had them on fired up the lathe to fly cut the tang top. When this is finished you will see a roller action coming out of that humongous lump of steel, mined, don`t do it with gummies on, hot bits of swarf in them with bare feet you learn a new quick step dance,

.

.

, need I say more. Aaa, yes, no Micky ,it`s not cutting those round holes.

, need I say more. Aaa, yes, no Micky ,it`s not cutting those round holes.

-

07-05-2020, 07:32 PM #75

nah I think I can see how you doing it from that photo....your cuttter is "flyin around" and your piece of steel is moved into its orbit very carefully in controlled manner to remove metal.

Similar Threads

-

Making a Sharps Barrel in my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 273Last Post: 08-03-2021, 05:22 PM -

Rolling block

By rusl in forum Firearms, Optics and AccessoriesReplies: 26Last Post: 04-08-2019, 03:07 PM -

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

189Likes

189Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks