dont know if Ive mentioned it before...but you are a clever bugga.......very clever indeed.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 76 to 90 of 106

-

07-05-2020, 07:34 PM #76

-

-

07-05-2020, 07:41 PM #77

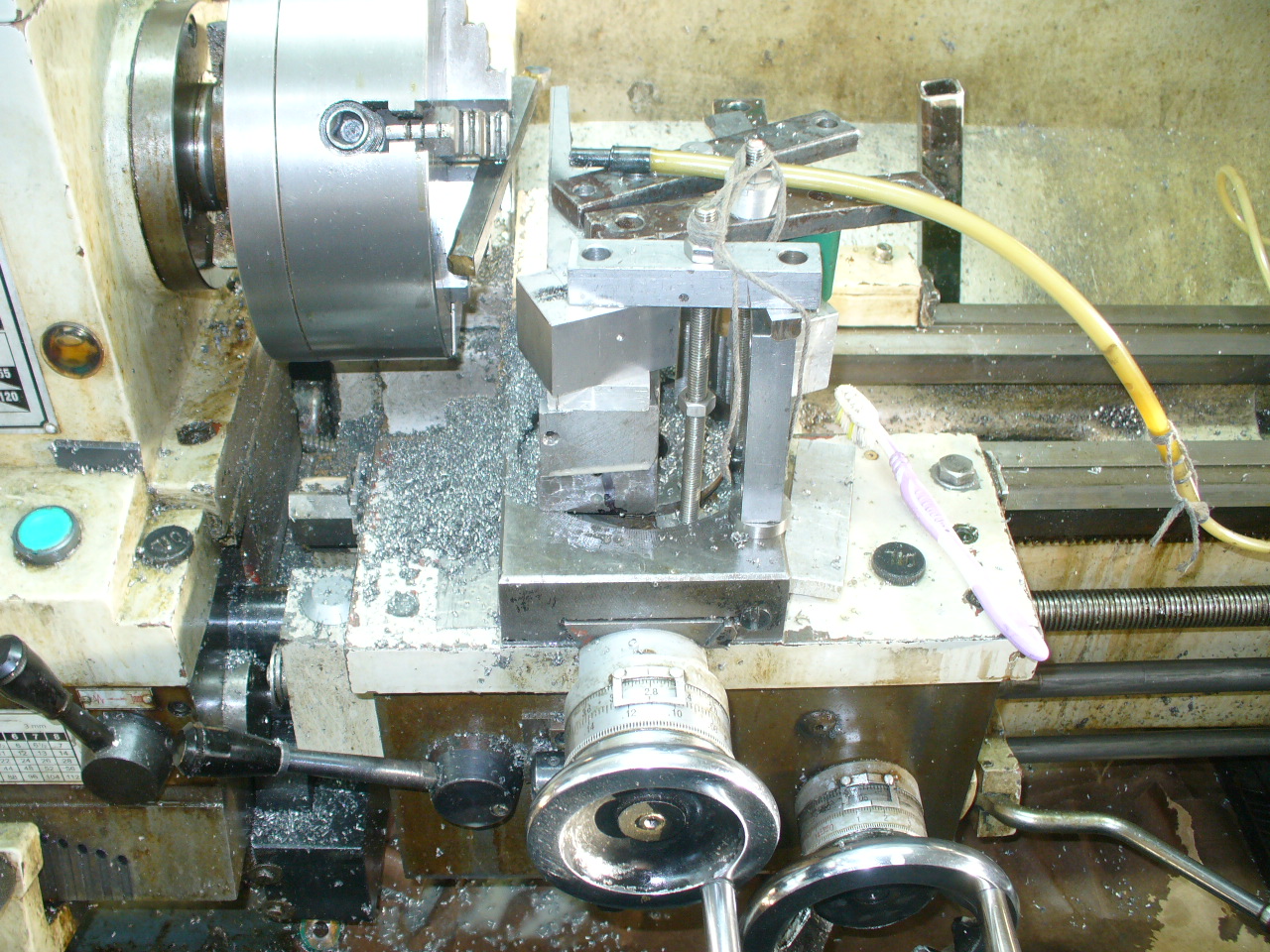

Got it, good lad, it`s clamped on the cross slide and it moves form left to right, in front of the chuck, move in 0.015" fly cutter spinning slowly and cross slide in feed and it slowly cuts off very hot bits of steel that seam to like my blood gun boots.

-

07-05-2020, 07:58 PM #78Member

- Join Date

- May 2016

- Location

- carterton

- Posts

- 1,050

inspirational

-

07-05-2020, 08:04 PM #79

Hope your hearing aids are turned off Doug.

Slimming nicely.Real guns start with the number 3 or bigger and make two holes, one in and one out

-

08-05-2020, 10:07 AM #80

-

08-05-2020, 08:11 PM #81

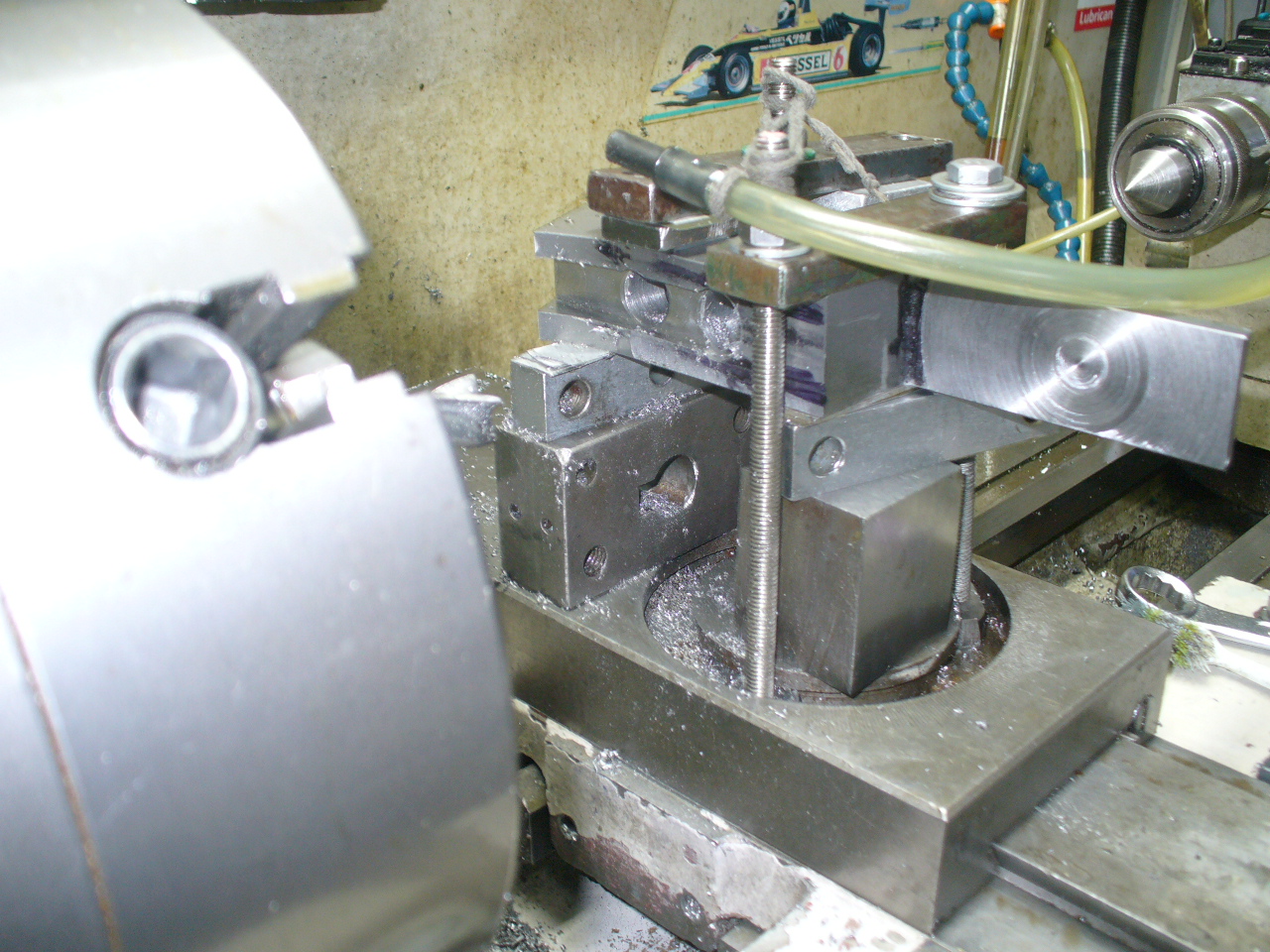

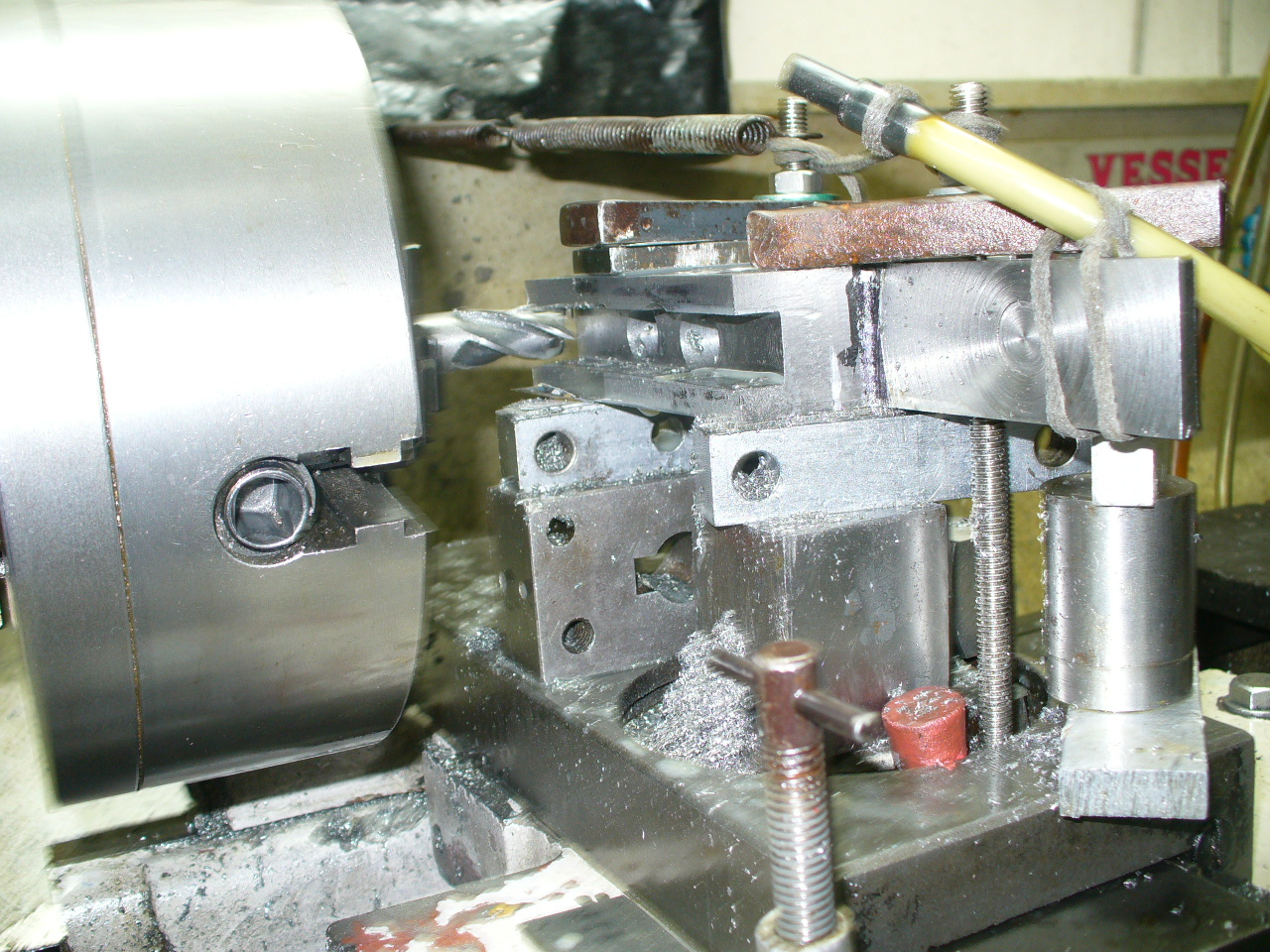

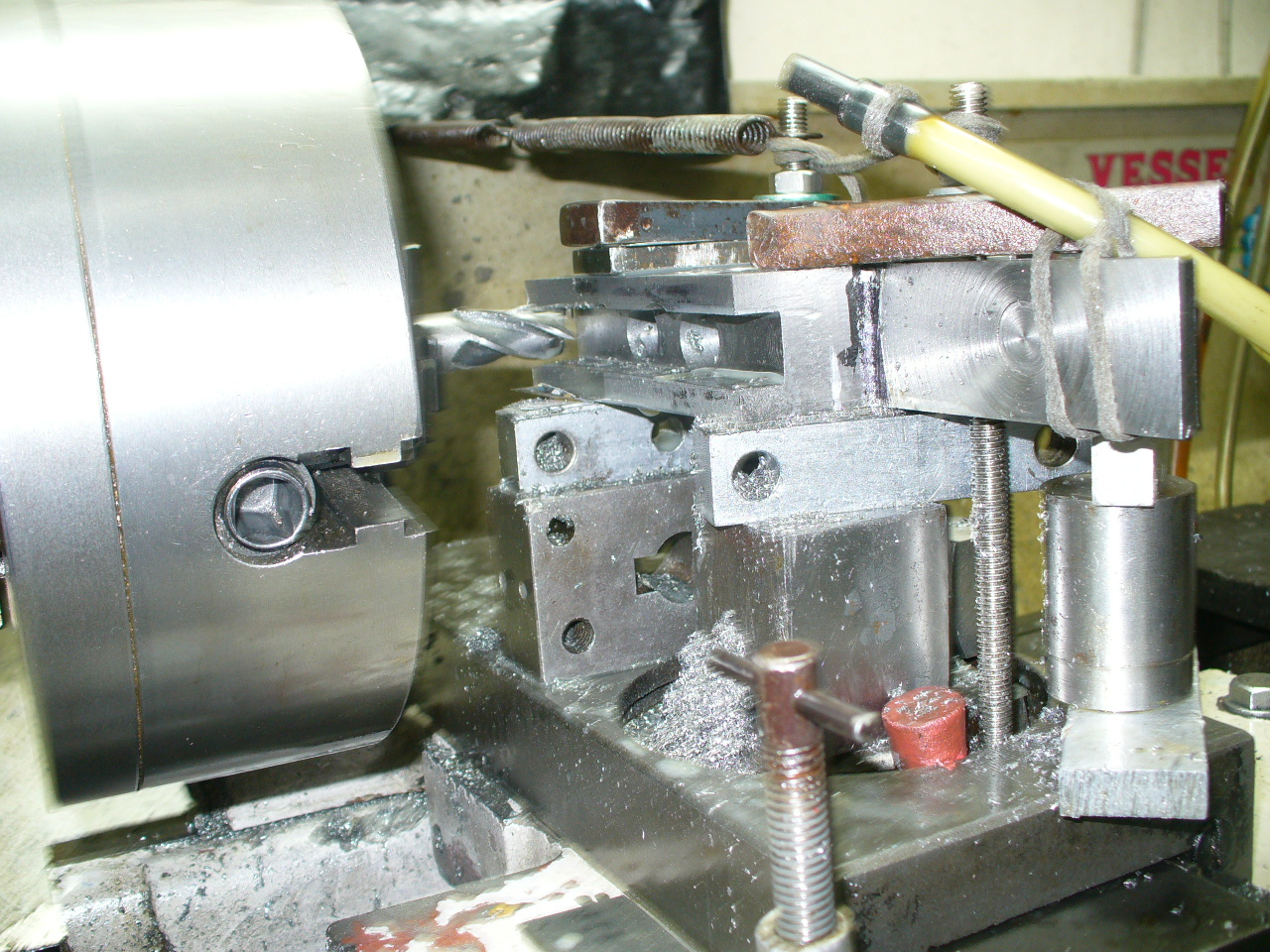

Hi here`s a bigger pic of some clever bugger stuff, I forgot to mention it`s the saddle that's moved in .015" and clamped up, them the chuck`s turned on, cross slide is on infeed and cutter then slices of .015" of bits of steel. This is coming along fast so better have think about barrels as I have the steel ready first job will be to give the gun drill a sharpen up, yes I do it on my lathe, yep , I`ll show you.

, the big look at it.

, the big look at it.

, two barrels to be.

, two barrels to be.

-

09-05-2020, 07:23 AM #82Member

- Join Date

- Feb 2013

- Location

- Mangakino

- Posts

- 1,867

I find this very interesting keep it coming.

-

11-05-2020, 09:42 AM #83

I love the four jaw as a fly cutter but it still gives me the creeps for some reason. I know it shouldn't, but it does

Loving the build updates!

Loving the build updates!

-

11-05-2020, 01:49 PM #84

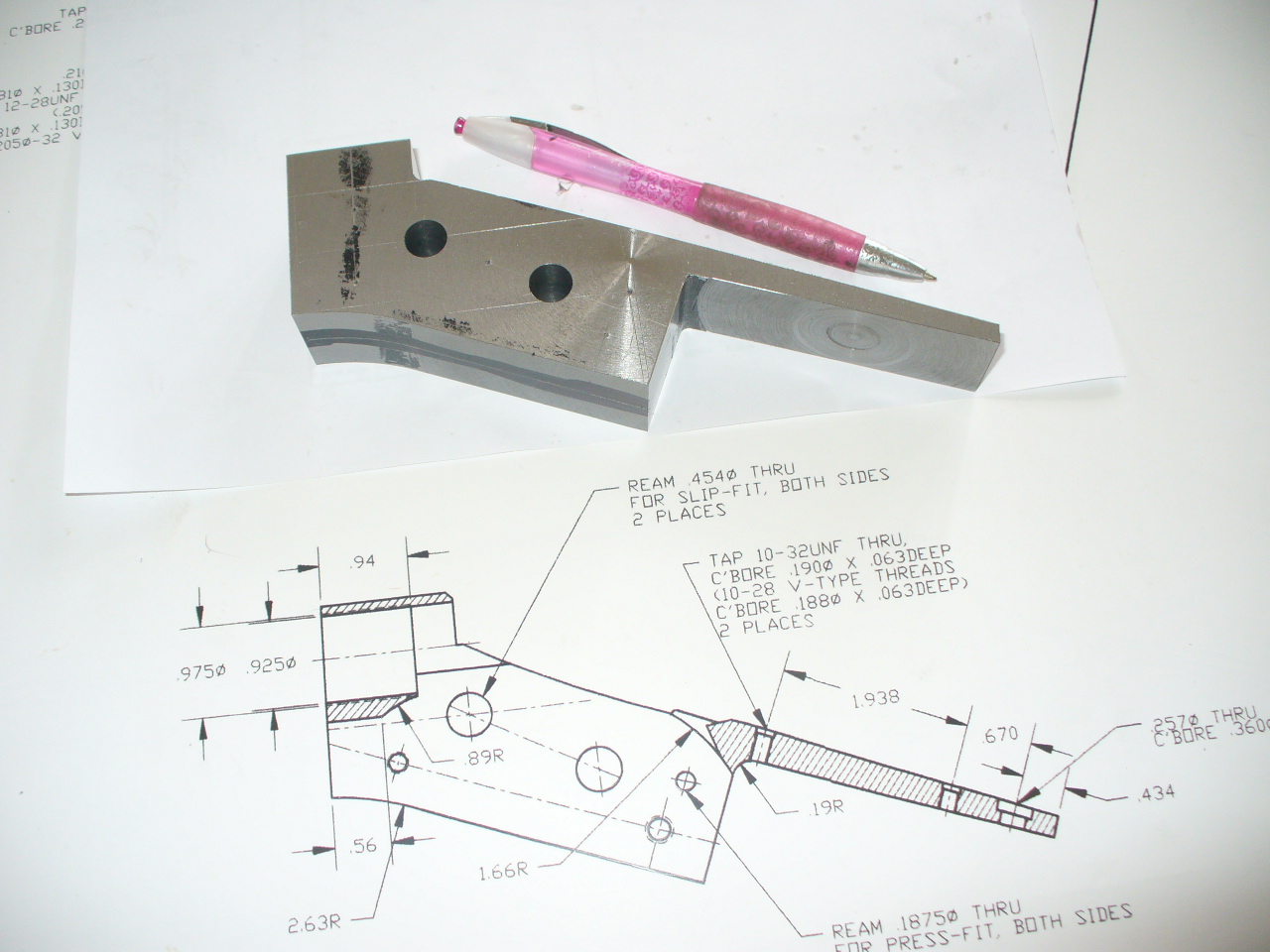

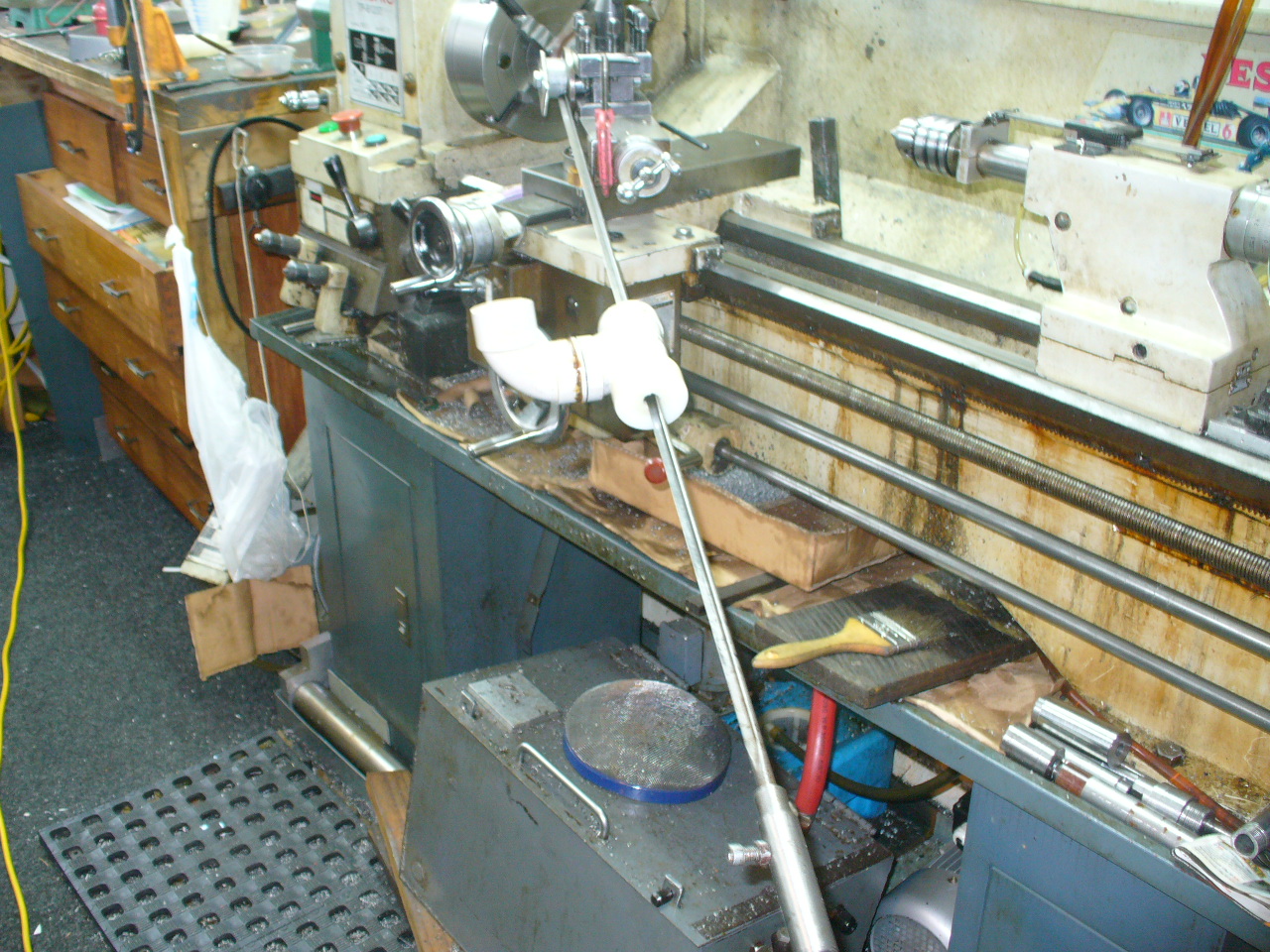

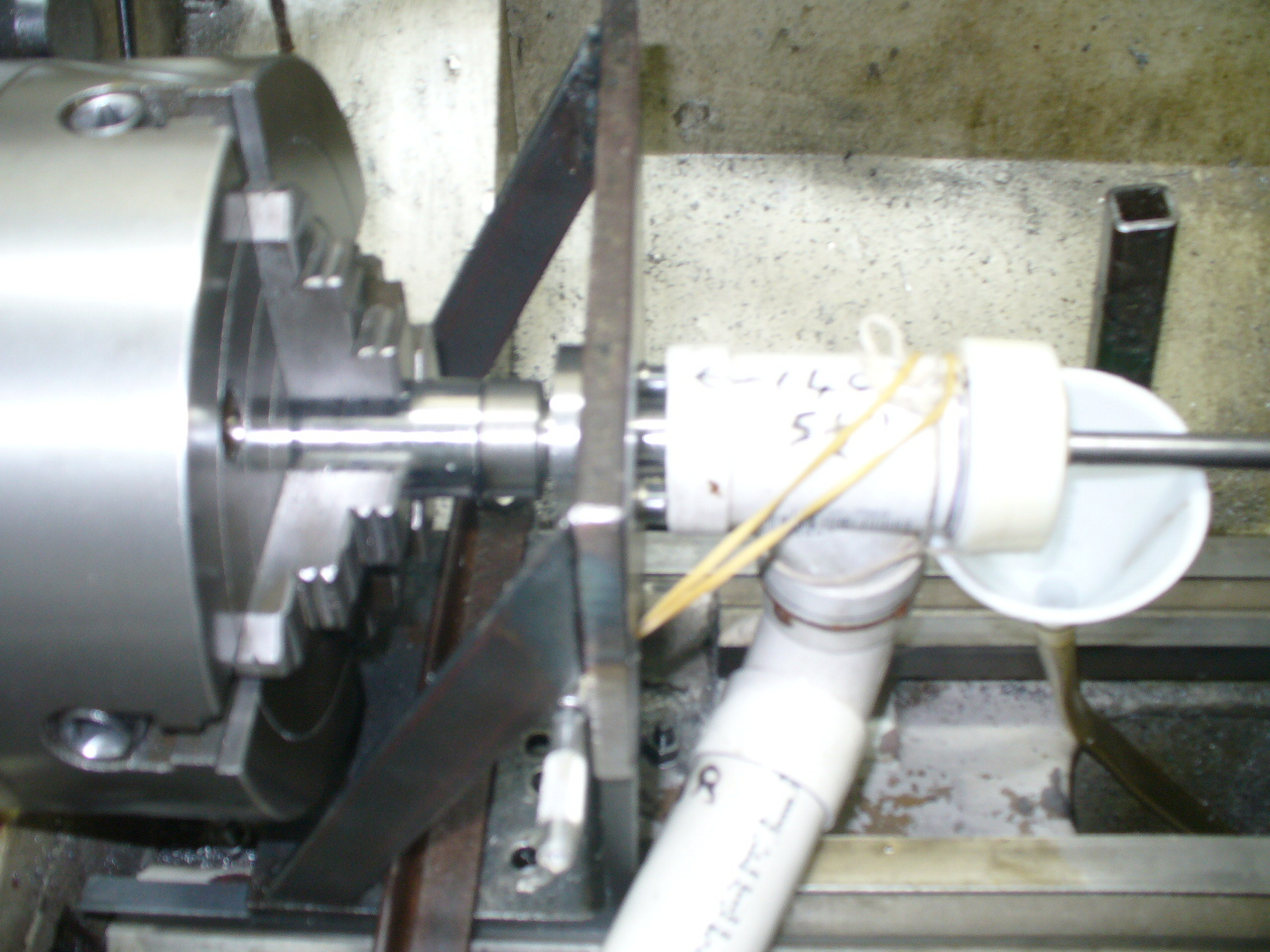

Well you just make sure it`s all clamped up nice and tight, then just small cuts nice and slowly. They say in machining you make hast slowly and now you can see the transformation from round lump of steel to a thing of beauty, a roller action block, it`s getting there. But will be having a change of projects at this stage, but don`t worry ,I`ll be back to it. I`m just hanging out to see if I can make a better barrel, so just gave the gun drill a tickle up with the diamond grind wheel, just .002" to refresh the edge so it`s nice and sharp for the 4140 steel. The drill is 48" long, has a grove running down it for the chips to flush out as you are drilling and that plastic bit of pluming is my chip box. diverts the oil and chips back to the chip catcher and oil tank.

, Very nice.

, Very nice.

, Grind wheel ready and T/C tipped drill lined up to sharpen.

, Grind wheel ready and T/C tipped drill lined up to sharpen.

, it`s 48" long and it saves me $50 if I do it myself.

, it`s 48" long and it saves me $50 if I do it myself.

, You may just see the shiny bit that's been ground on the face, it`s ready to go.

, You may just see the shiny bit that's been ground on the face, it`s ready to go.

-

13-05-2020, 12:36 PM #85

I take it the chip box rides up against the muzzle (or muzzle projects into the chip box a bit) and as the swarf pushes out of the barrel it drops free?

I like seeing your lathe based solutions to problems. Being flexible in problem solving is an excellent skill.

-

14-05-2020, 10:46 PM #86

No, The angle bracket is clamped in place holding the gun drill guide that is set at lathe centre line and barrel stock in four jaw chuck is pressing on the front of it with Oring seal. The body of drill guide extends through bracket and chip pluming is pressed over this with a seal. Shiny steel is barrel stock, then drill guide holding chip box. All has come to a halt , water contamination in my oil has stuff up one of my oil pumps, have a spear one so cooking oil to get rid of the water and check if new pump works.

, This is how it works.

, This is how it works.

-

02-07-2020, 09:10 PM #87

Ok, Got the barrel making bit sorted so back to the roller action, it now has two holes drilled for milling clearance and after careful setting up have started milling out the guts where the breach block and hammer goes. I have also rebuild a deck as I could see a bit of rot getting into the old one, so that`s why things are a bit slow, but then what`s the rush . Put in a order for a T/Carbide .450" pull through reamer from the U S, so one run through should see the bore ready for rifling, that`s when I get it, well no rush,

, Two holes.

, Two holes.

, Milling started.

, Milling started.

, Nice new deck.

, Nice new deck.

,

,

-

02-07-2020, 10:41 PM #88Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,353

I have to admire your tenacity! That is lot of work without a milling slide, buggerizing around with packers and a dial gauge before you can make a cut! It just goes to show what can be done on a lathe when liberally mixed with stubbornness and ingenuity. The pollys will never win!!

-

03-07-2020, 01:32 AM #89Member

- Join Date

- Jun 2013

- Location

- Middle Earth

- Posts

- 4,573

What is the spring for on top? To stop backlash?

-

03-07-2020, 09:58 AM #90Member

- Join Date

- Aug 2012

- Location

- helensville nz

- Posts

- 4,742

Comeing along nicely Doug

Similar Threads

-

Making a Sharps Barrel in my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 273Last Post: 08-03-2021, 05:22 PM -

Rolling block

By rusl in forum Firearms, Optics and AccessoriesReplies: 26Last Post: 04-08-2019, 03:07 PM -

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

189Likes

189Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks