Hi Guys, Back from a few days up north at Kerikeri, saw a weather window so loaded up my small caravan with eggs, bacon, sausages, onions and when I got to the camp site, there`s a home kill butcher across the road, best aged sirloin steaks I`v come across. Great stuff, one needs a break to get healthy , well it was a bit of a walk to the butchers and had to have a few beers when I got back,.

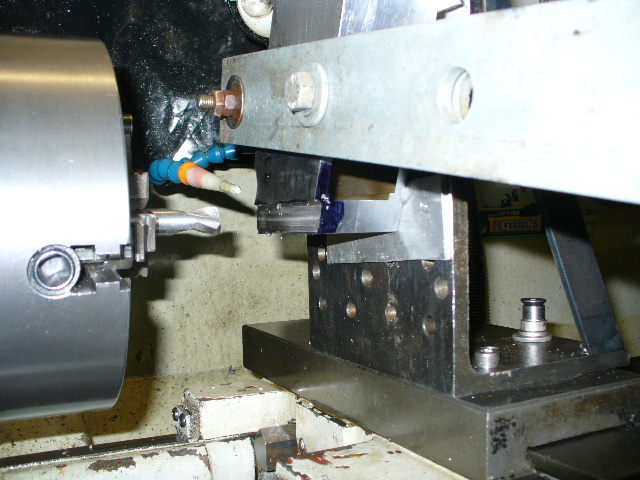

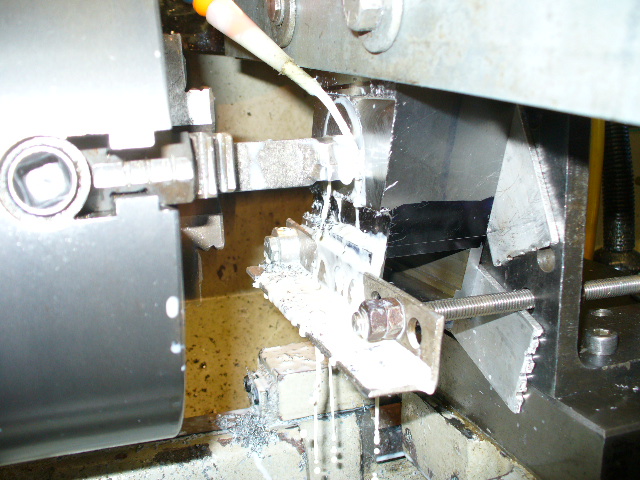

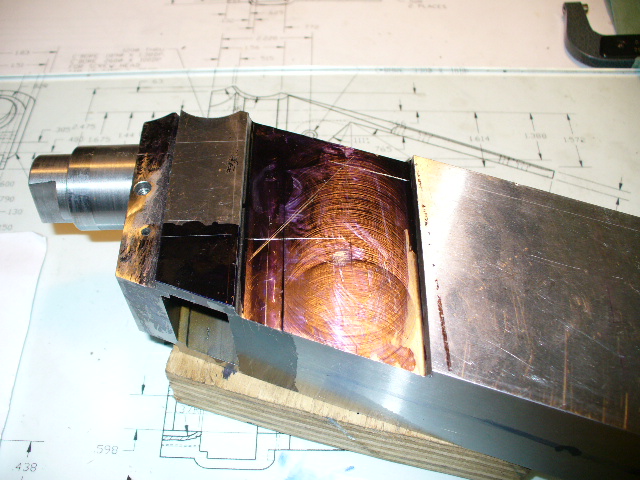

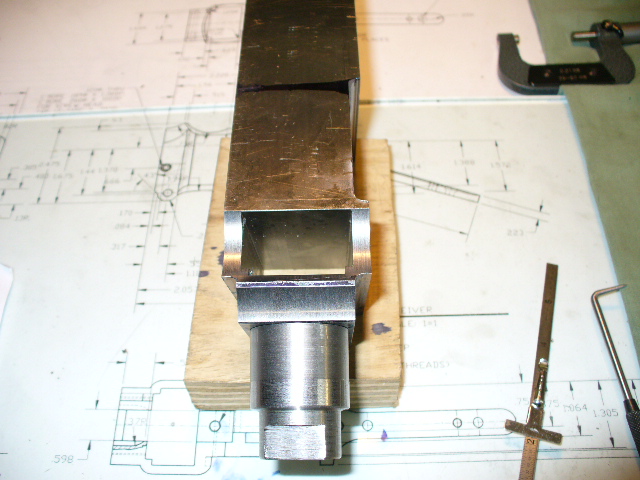

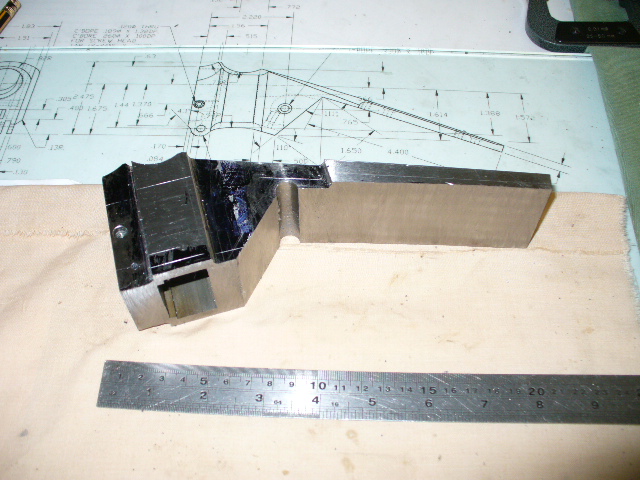

So have just finished cutting the radis at the top of the Sharps receiver after clamping it to my angle bracket on the cross slide and slowly fly cutting out at the top, one more bit done. Homebrew.357.

, Cutting out the radis .

, Bit more done.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 136 to 150 of 274

-

14-06-2015, 09:53 PM #136

-

-

15-06-2015, 10:28 AM #137

-

16-06-2015, 10:11 AM #138Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,184

@homebrew -mate with your talents you could machine yourself a new hipjoint after the sharps is finished.imagine rollin up to the surgeon with it -'righto doc -ive milled it when can ya fit the bloody thing"-jeez man the six milliondollar man would be green with envy!

-

16-06-2015, 08:34 PM #139

Hi Kotuku, When I went in to have my first hip joint removed, I said "What do you do with the old one " , yer, I`v got it in my draw , thinking how can I use it in the Sharps build.

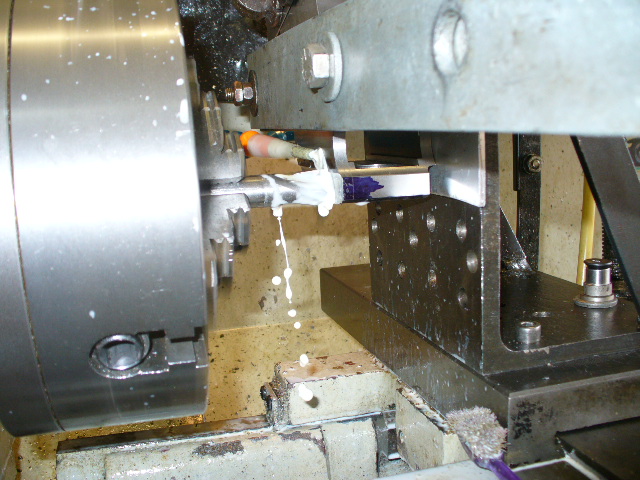

Make a great knob for my Hawken ram rod . Anyway, I`m drilling a hole in a steel shaft at the moment, blank barrel for a customer's muzzle loader, my fame is getting out there.

Make a great knob for my Hawken ram rod . Anyway, I`m drilling a hole in a steel shaft at the moment, blank barrel for a customer's muzzle loader, my fame is getting out there.  , Cheers, Homebrew.357.

, Cheers, Homebrew.357.

-

16-06-2015, 09:06 PM #140Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,184

you are on it my man -imagine what you could do with a politicians ballsack!

-

16-06-2015, 09:21 PM #141Member

- Join Date

- Jan 2013

- Location

- Home - mainland nz, actual - Auckland

- Posts

- 5,455

-

18-06-2015, 08:19 PM #142

I don`t think it goes for our Auckland stallion, hear he has spent $20.000 of tax payers money on a new bedroom in his council offices, he would be wise to keep away from our cannon shoots, the boys are always looking out for large balls to shoot.

Homebrew.357.

Homebrew.357.

-

23-06-2015, 06:56 PM #143Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,184

judgin by the way things are goin -youd put him down the barrelballs&all wouldnt you .

when thats done hang about cause weve got him with mammaries here in shakeytown who could happily follow him from my POV!face like a narwhals minge!

ya could at a pinch use her acolytes as assorted pullthroughs!

-

06-07-2015, 08:13 PM #144

Hi Kotuku, Bet there are a few narwhals faces in the windy city,

those mainland boys just upped there kilts and got stuck in and I bet they put those beer handles to good use.

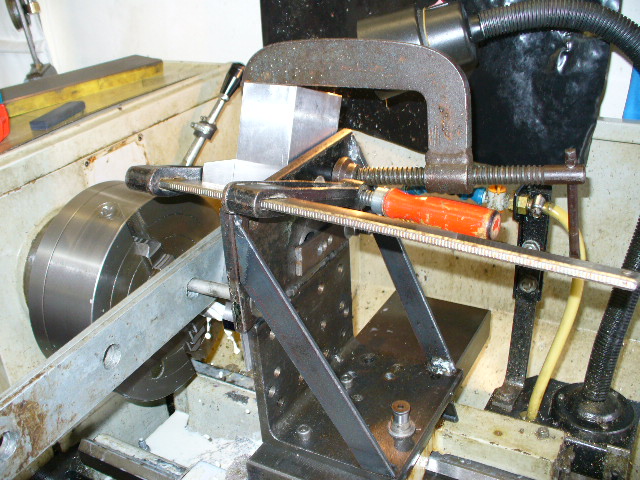

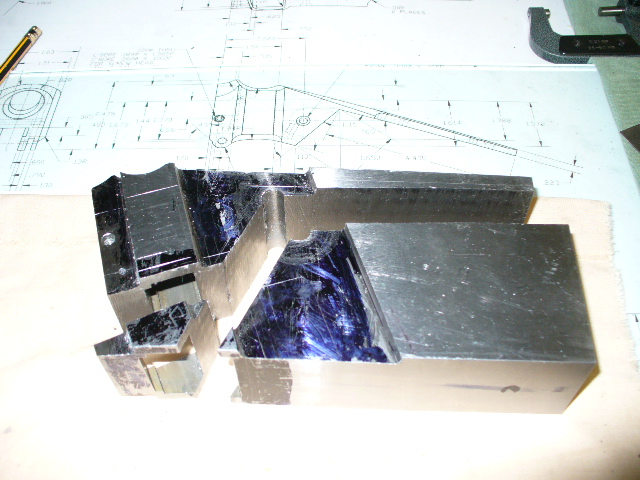

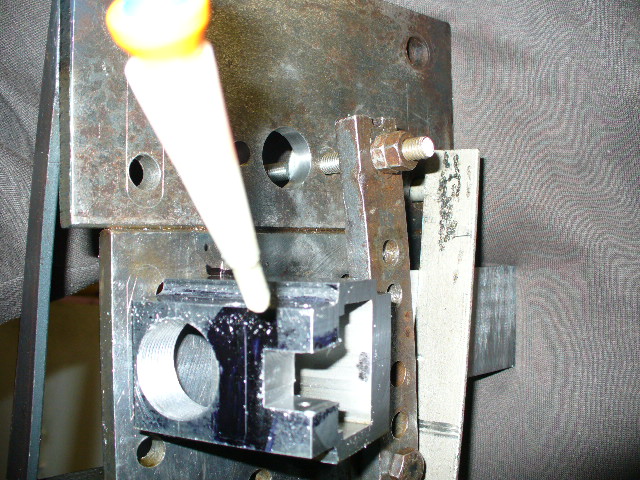

those mainland boys just upped there kilts and got stuck in and I bet they put those beer handles to good use.  . Now the front of the receiver is milled in a bit on both sides, so clamped onto my angle bracket to get the job done with milling cutter in four jaw chuck. The mill has rounded edges , so no sharp corners that can cause stress cracks, it`s getting there, Homebrew.357.

. Now the front of the receiver is milled in a bit on both sides, so clamped onto my angle bracket to get the job done with milling cutter in four jaw chuck. The mill has rounded edges , so no sharp corners that can cause stress cracks, it`s getting there, Homebrew.357.

, Clamped on to mill the first side.

, Clamped on to mill the first side.  , The other side.

, The other side.  , You can never have enough clamps.

, You can never have enough clamps.  , Milled both sides, job done.

, Milled both sides, job done.

-

07-07-2015, 06:01 PM #145Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,184

mate,youre a bloody gem ,ya bloods worth bottlin!

-

19-07-2015, 08:55 PM #146

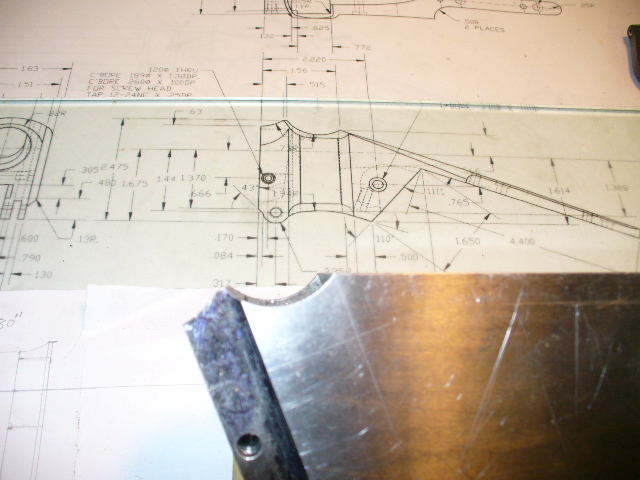

Hi Kotuku, No I`m doing it the other way around, what I`v bottled is going into my blood. Now have also ground a radis on the front of the receiver and milled out a large flat on the left side to bring it to the right size as the block is a bit larger than required, did this with a t/c fly cutter off centre so all was cut out in one go. Homebrew.357.

pic 166, Radis on face. pic`s 167, 168, milling out large flat. pic 170, job done.

,

,  ,

, ,

, .

.

-

20-07-2015, 08:25 PM #147

Hi, The receiver is a bit over weight with a goodly lot that has to come off, so sent it to boot camp for a work out to lose a bit, but they grabbed me as well so I had a good work out as well. Good to have there`s fitness classes in winter, gives me something to do.

Homebrew.357.

Homebrew.357.

, top view.

, top view.  , Slimed down.

, Slimed down.  , Cutting out some of the flab.

, Cutting out some of the flab.  , A lean mean machine.

, A lean mean machine.

-

21-07-2015, 09:06 PM #148

And to those who think I have a electric band saw,

, NO I don`t, I just put a hack saw blade into my bush camping saw and I`m the champion arm wrestler in the retired men's club.

, NO I don`t, I just put a hack saw blade into my bush camping saw and I`m the champion arm wrestler in the retired men's club.  . Homebrew.357.

. Homebrew.357. ,

,  ,

,

-

22-07-2015, 01:28 AM #149

-

29-07-2015, 09:15 PM #150

The under lever fits in a slot under the receiver , so set up and with a off centred mill and cut out to full depth. At the top of this slot a tee cut is milled for the lever spring , I made up a cutter from an old milling bit and used the fore jaw chuck to adjust the in feed. Also drilled the hole for the lever pin. With a bit of cleaning up and fine sanding will see if the breech block and under lever fit and work ok.

,Homebrew.357.

,Homebrew.357. , Milling lever slot.

, Milling lever slot.  , Bit more to go.

, Bit more to go.  , Tee slot for spring at top.

, Tee slot for spring at top.

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks