Looking great!

Kj

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 151 to 165 of 274

-

30-07-2015, 08:37 PM #151

-

-

30-07-2015, 09:31 PM #152

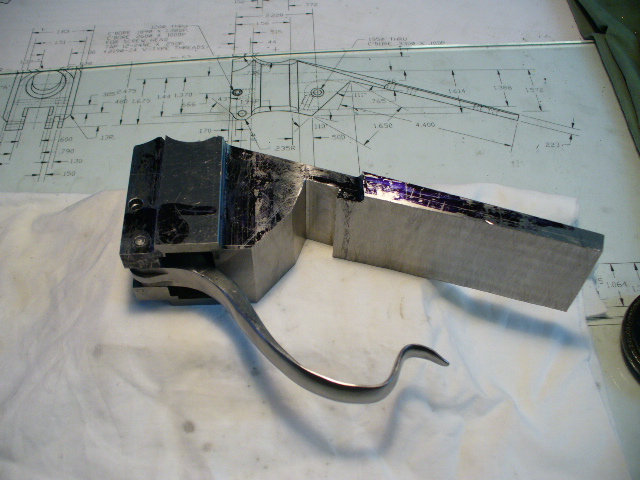

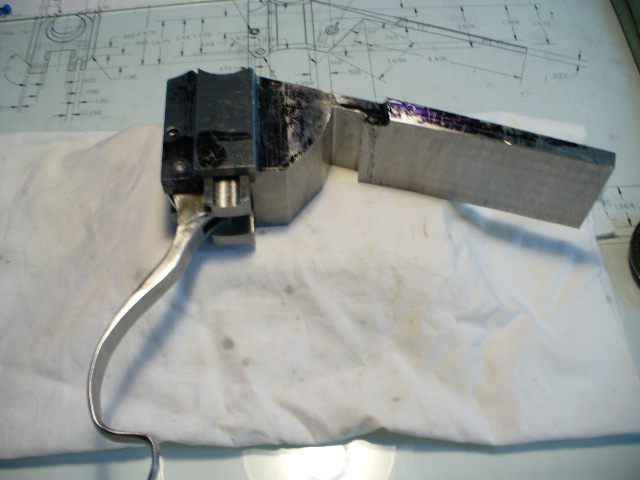

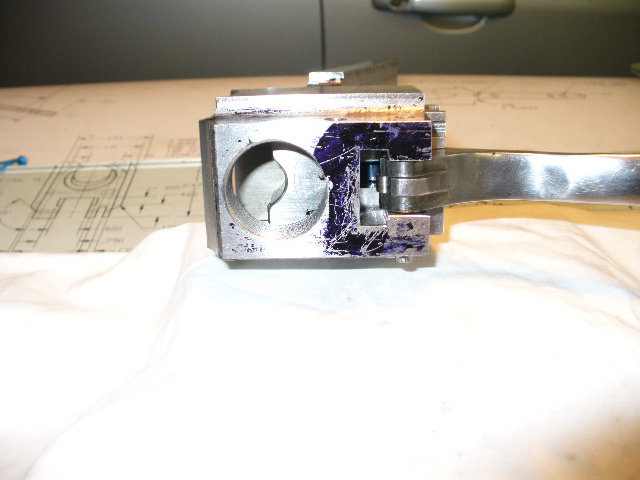

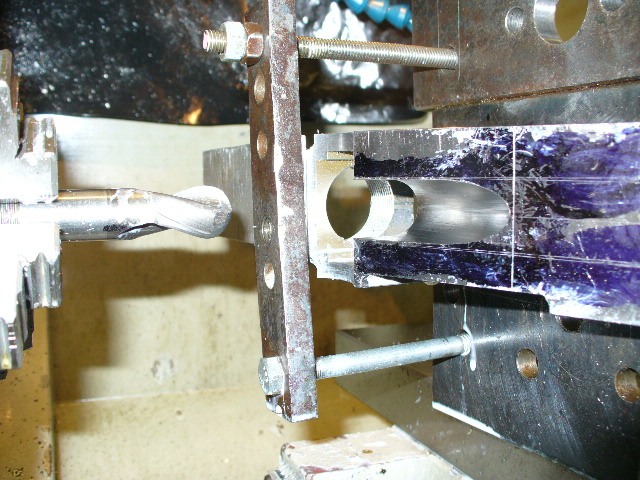

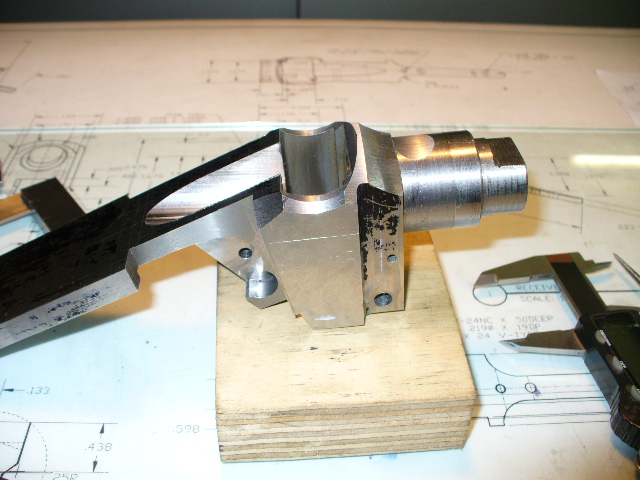

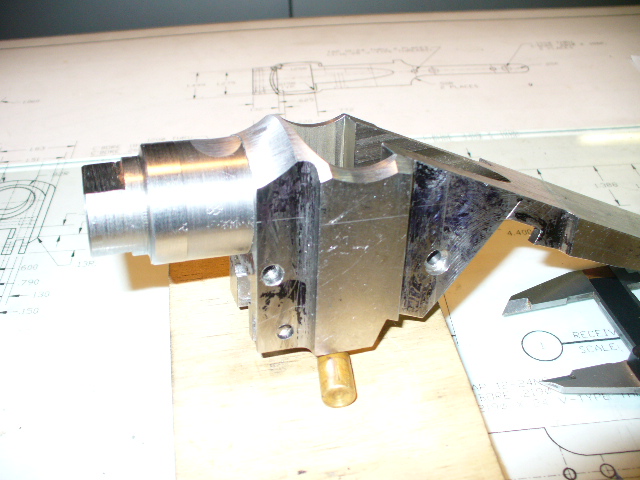

Hi guys, Finally a break through in this build, yes, the breech block and lever are the sweetest fitting things I have made , move snug and firm. Hay, this gun may really get to work, I know I had a hand with the receiver hole , but when it works like this, wow,

. Homebrew.357.

. Homebrew.357.  , Breech block, lever sweet as.

, Breech block, lever sweet as.  , Lever down, breech open.

, Lever down, breech open.  , Front view.

, Front view.

-

07-08-2015, 08:53 PM #153

A bit more work on the receiver, milled to final size the back sloping bit under the tang, a bit of a mission, had to use a long I" boring bar, but with small cuts and going nice and slowly I got there. And have also milled the small slot for the b/block lever retaining pin. So with that lot done I set up to cut out the top U shaped bit that lets the cartridge slide into the chamber, milled out with a small mill first and then finish to shape with a rounded bull nose mill, it`s coming on.

, Hombrew.357.

, Hombrew.357.  , Milling with long fly cutter.

, Milling with long fly cutter.  , It`s doing the job..

, It`s doing the job..  , milling out cartridge slot.

, milling out cartridge slot.

-

11-08-2015, 08:35 PM #154

Hi, Cutting out a slot first helped with the round nose mill as it was not cutting a large area , but still cut it nice and slowly. The cutter running at centre milled a final slot size of .725" , but I needed .800", so I just moved the cutter off centre a bit till I got the right size. Had a barrel, receiver and breech block fit out and a cartridge slides in nicely .

, This is getting juicy , it`s going to go Bang one day,

, This is getting juicy , it`s going to go Bang one day,  . Homebrew.357.

. Homebrew.357.

, Cutting out the radis.

, Cutting out the radis.  , Looking good.

, Looking good.  , looking better.

, looking better.  , All of them plus nice.

, All of them plus nice.

-

13-08-2015, 08:55 PM #155

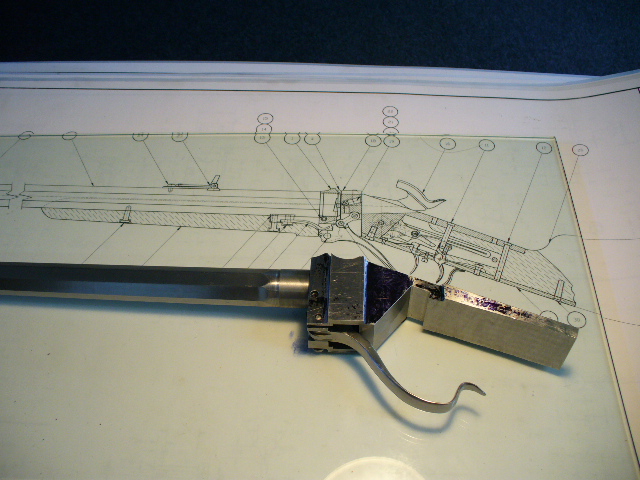

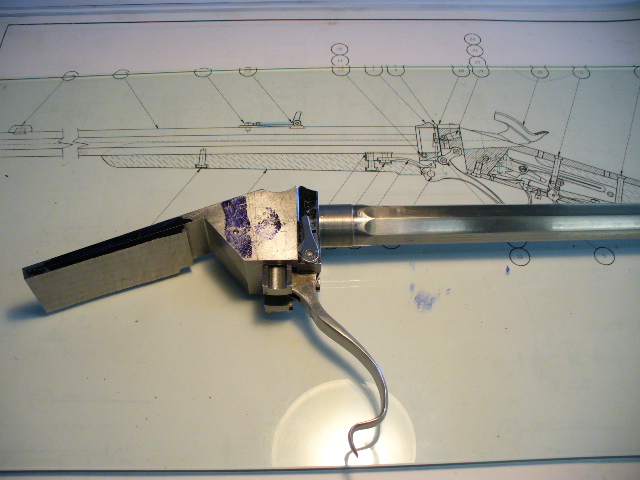

Hi all, Had a trial fit out to see if all was working ok and I had not made any stuff ups.

. I can report all is looking great, The barrel is not right in yet, needs a bit machined off for head spacing and a bit more machining of the receiver yet. But hey, It`s coming on good, I`v even loaded up some cartridges for the first shoot out.

. I can report all is looking great, The barrel is not right in yet, needs a bit machined off for head spacing and a bit more machining of the receiver yet. But hey, It`s coming on good, I`v even loaded up some cartridges for the first shoot out.  , Cheers, Hombrew.357.

, Cheers, Hombrew.357.

, All fits together.

, All fits together.  , The breech opens.

, The breech opens.  , It`s going to go bang one day.

, It`s going to go bang one day.  , Trigger finger is getting itchy.

, Trigger finger is getting itchy.

-

16-09-2015, 08:02 PM #156

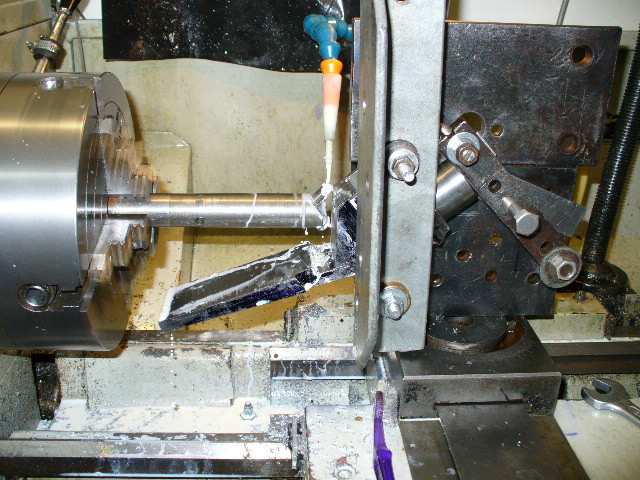

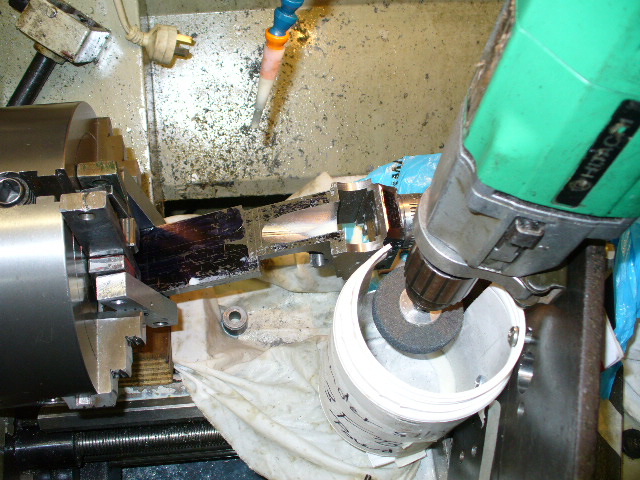

Hi all, The receiver has a radius on the top, sides of the b/block, so with my normal ingenuity

I set it up on the lathe and using my electric drill clamped to the angle bracket with a grinding wheel of the right size I slowly ground it by the old rock and roll way. In feed with cross slide and I just moved the saddle along for the side of the b/block area. Now grinding on a lathe is a no no,

I set it up on the lathe and using my electric drill clamped to the angle bracket with a grinding wheel of the right size I slowly ground it by the old rock and roll way. In feed with cross slide and I just moved the saddle along for the side of the b/block area. Now grinding on a lathe is a no no, , the grit will stuff up the lathe fast if nothing is done to stop the grit getting on the bed ways, I know this, so you will see lots of rags on the lathe to stop this, its not to keep it warm.

, the grit will stuff up the lathe fast if nothing is done to stop the grit getting on the bed ways, I know this, so you will see lots of rags on the lathe to stop this, its not to keep it warm.  , Homebrew.357.

, Homebrew.357.

, The set up for grinding.

, The set up for grinding.  , One end in the fore jaw chuck.

, One end in the fore jaw chuck.  , Off centre for the radius.

, Off centre for the radius.  , The drill, G/wheel, lots of rags.

, The drill, G/wheel, lots of rags.

-

18-09-2015, 12:58 AM #157

I still think this is one of,if not the, most interesting threads I have seen on this forum.

Using Tapatalk

-

18-09-2015, 08:41 AM #158Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,239

HByou are a bloody genius and a determined one at that.methinks (like the others)this is gonna be a very special weapon.My mind boggles at your talents and enginuety.

-

18-09-2015, 01:57 PM #159

-

18-09-2015, 03:56 PM #160Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,239

home brew -can we all gather online and give you the big countdown when HB1 launches her first missile??.

PS-do nth korea know about this devastating new artillery piece??

-

18-09-2015, 05:56 PM #161

Hi Guys, I put a thread in "Hunts" , I`m taking the Hawken on a trip for Sika, now the pic of me firing it was quite funny. On my right was a Korean guy with a baby ak7 type rifle, 40 round mag, .223 cal and a large box of amo to start a war. He was looking at me wondering why I was "cleaning" my gun so much, ramming home the bullet , he had never seen a muzzle loader, I capped and set her up and fired, boom, large cloud of smoke, he jumped up yelling, "Buddy Hell", What the **#@%%$^ hell is that thing.

mg So they know about the Hawken. So the grinding went ok and now have a nice radis on front and sides. It`s coming on, Homebrew.357.

mg So they know about the Hawken. So the grinding went ok and now have a nice radis on front and sides. It`s coming on, Homebrew.357.

, Grinding working good.

, Grinding working good.  , Coming on nicely.

, Coming on nicely.  , Radius done.

, Radius done.  , Looking good.

, Looking good.

-

22-09-2015, 09:38 PM #162

Hi All, The receiver sides are rounded, but it was easer to grind them to 45%, on my drill press using my long suffering x-y vice . As this is a Kiwi Sharps I`m allowed to cheat,

.

.

Also fitted the side plate with hammer, a bit of filling got it fitting nicely . I have stress relieved the receiver , in the oven for 4 hours at 200c , came out nice and tender . I'm surprised myself how this is coming along, I think I`m better than I thought I was. , Homebrew.357.

, Homebrew.357.  , Grinding at 45% the side bits.

, Grinding at 45% the side bits.  , Side plate fits in.

, Side plate fits in.  , Stating to look the part.

, Stating to look the part.

-

22-09-2015, 11:00 PM #163

Clocking up a fair few shed hours there Homebrew...are you keeping a track of them?

"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

24-09-2015, 08:45 PM #164

Hell no, I just tell the wife I`m going to tidy up the garage and then I get side-tracked and start working on the gun. I wouldn't count it in hours, more like years, and just doing all this in half of my garage, other half for the car. Kotuku I don`t think it would wise if I fired the Sharps in the lounge while sitting at the computer and will not be firing it until a proof test is done, that's why I was looking for someone with a farm ,but will probably take it on a goat hunt for all the testing and good excuse to go on a hunting trip. The proofing is done before the gun is finished, no good finishing it and then blow it up, when the barrel is fitted and it will fire primers loaded in cases, every time, then the proof test, It`s got to be safe. In the mean time we are planning our big O E down the south Island in our small caravan for three months to see the main land.

, Cheers, Homebrew.357.

, Cheers, Homebrew.357.

-

24-09-2015, 09:49 PM #165

I've got a farm you can proof test it on if you get stuck. We have good cell phone coverage and waikato hospital is only 30 minutes away

. But seriously, you're welcome to test it down here if you want.

. But seriously, you're welcome to test it down here if you want.

Kj

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks