Great stuff @homebrew.357

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 274

-

07-10-2014, 08:20 PM #16Member

- Join Date

- Dec 2013

- Posts

- 603

-

-

08-10-2014, 08:50 AM #17

HI, Yes they recommend 0.0002" per revaluation, barrel speeds of 2/5000 rpms, and 1000 psi oil presser . The drill goes in one inch per minute and it takes 1/2 hour per barrel, I a lot slower. Homebrew.357.

-

14-10-2014, 07:43 PM #18

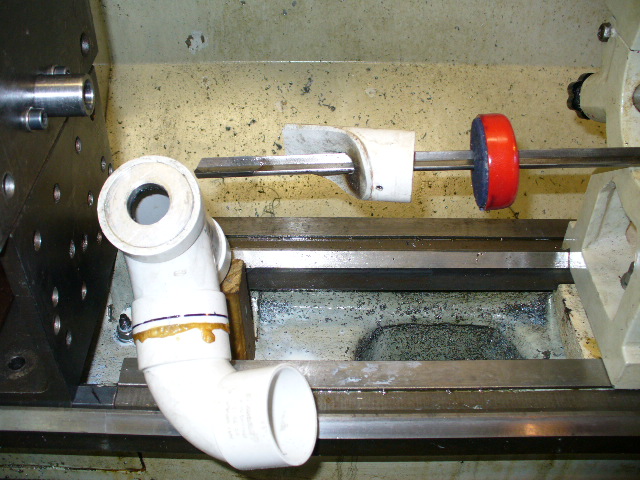

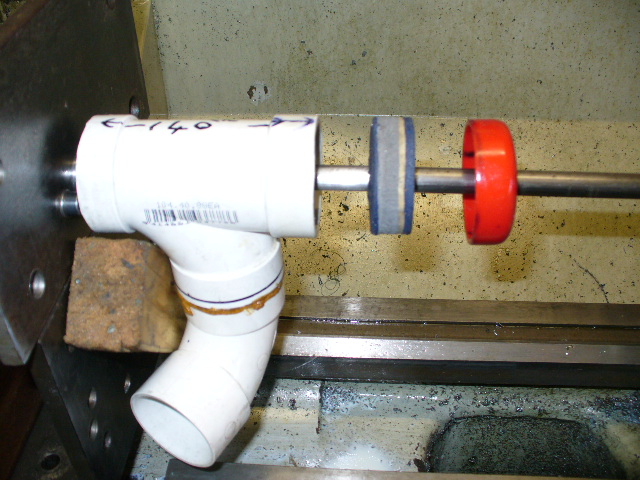

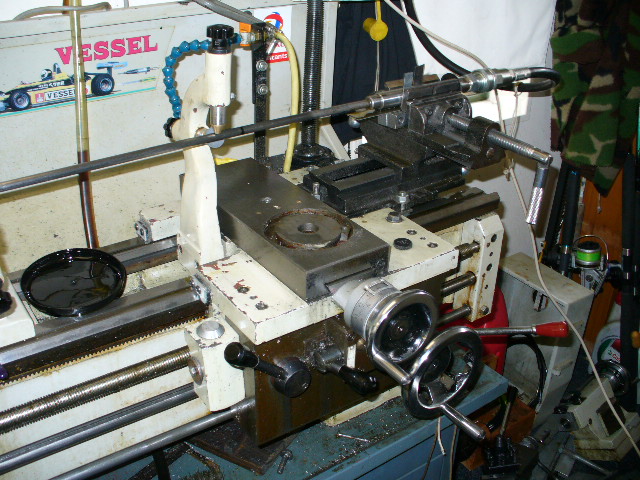

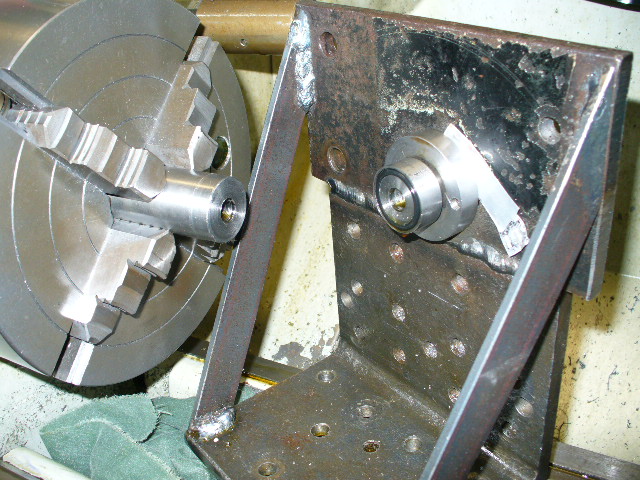

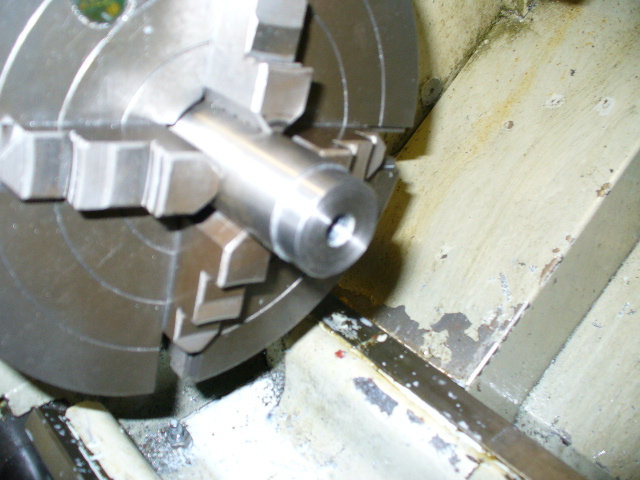

Ok, The barrel is set up ready to drill, so here is the setup for the gun drill. The following steady and fixed one are mounted on the lathe to help guide the gun drill and keep it straight . The chip catching assembly is put on the back of the drill guild , has a o ring seal, the gun drill is set up with it`s back end seals, the drill goes through them so no oil can leak out. drill is clamped in the vice at centre hight and oil hose is connected. pic`s, Homebrew.357.

-

14-10-2014, 08:27 PM #19

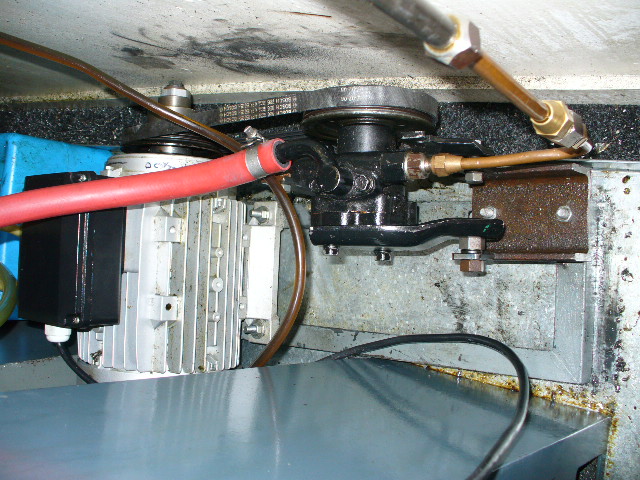

Ok, some more pic`s, The outlet tube has a clear window so I can see the chips flowing out, keeps me happy. Oil and chips go down to the chip strainer and oil goes into the tank in a go around cycle. The motor and car pump are at the back of the lathe and oil in pumped up to the junction box , red tap is tank return, at left, gate tap at right is to gun drill when left one is shut. The pressure is governed by the hole in the gun drill, I got 300 psi, worked all right as the chips soon filled up the box. Have to empty the chips out three times for this barrel, which by the way is 4140 steel. More pic`s, Homebrew.357.

,gun drill clamped in.

,gun drill clamped in.  , Chip catcher assy.

, Chip catcher assy.  , drill in ready to go.

, drill in ready to go.  , All back to the tank.

, All back to the tank.

-

14-10-2014, 08:44 PM #20Member

- Join Date

- Jun 2014

- Location

- Middle Earth

- Posts

- 231

You are Gold, keep it up mate

-

14-10-2014, 08:50 PM #21

The junction box, Chip catcher full , motor and pump,

![Name: P1010175[1].JPG

Views: 1416

Size: 170.8 KB](https://www.nzhuntingandshooting.co.nz/attachments/f53/30019d1413272759-making-sharps-barrel-my-lathe-p1010175%5B1%5D.jpg)

, Lots of chips,

, Lots of chips,  ,Homebrew.357.

,Homebrew.357.

-

21-10-2014, 12:44 AM #22Member

- Join Date

- Jul 2012

- Location

- Timaru

- Posts

- 890

is that a power steering pump? can it put out more than 300psi? cheers. like your work!

-

25-10-2014, 08:22 PM #23

Hi, Yes , The power steering pump will put out more presser , but in this case it is the hole in the gun drill that gives the presser. So to start things going, the gun drill is in the guide 1/16" back from the barrel stock, the lathe is started, 1200 rpms, then the oil pump , there is no presser and the oil is retuned to the tank via the red tap, just going around. After checking oil flow is ok, the gate tap to gun drill is opened and red tap is slowly closed untill all the oil is going through the gun drill, at 300 psi, The lathe saddle is engaged to start the drill in feed. After a bit the chips can be seen coming past the sight glass and into the chip oil filter , and yes the oil presser does drop a bit when it warms up 200psi, but the chips keep coming out. After three days you end up with something like this,

, And, this is my try with 4140 steel, next is how I reamed it ,

, And, this is my try with 4140 steel, next is how I reamed it , Homebrew.357.

Homebrew.357.

-

26-10-2014, 07:50 AM #24Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,401

Your a man of great patience! And an all round clever one, got offered a barrel drilling lathe with drills the other day, ex Tony Hawkins, no button dies for rifling though

Boom, cough,cough,cough

-

26-10-2014, 08:50 PM #25Member

- Join Date

- Jun 2013

- Location

- Middle Earth

- Posts

- 4,574

Getting the button dies is the easy part. Getting the gundrill lathe and the button pulling machine is the toughest. Also need a good oven for barrel metal stress relief.

-

28-10-2014, 09:54 AM #26

Well I`ll be blowed, I knew Tony at the NZDA, he would come to the bench rest shoot, pull out a length of 3x2" with a truck axle barrel ,98 action on it in .308 cal, scope on top and proceed to shoot one ragged hole at a 100m. Pissed off a lot of shooters with the good gear. He was a great guy who had to leave early.

To all around clever, add real low down weaseley tight wad , you see ,when I say oil in tank, I`m not saying (cutting oil), because It`s not, it`s hydraulic oil from my son`s Kanga digger, well it works alright. , pic`s, tank filling with ("cutting") oil, and barrel. Homebrew.357.

, pic`s, tank filling with ("cutting") oil, and barrel. Homebrew.357.

-

28-10-2014, 05:46 PM #27

shit that's awesome good stuff homebrew357

OPCz

If in doubt double tap

-

28-10-2014, 07:08 PM #28Tools not Toys

- Join Date

- Apr 2013

- Location

- wanaka

- Posts

- 277

Hey Mate this is some good stuff, keep the pics flowing, along with that cutting oil!

Slow is Smooth, Smooth is Fast.

-

28-10-2014, 09:10 PM #29Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,401

-

29-10-2014, 10:26 AM #30

Probably a dumb question but is it/are you going to rifle it? Or just leave it smoothbore?

"A party without cake is just a meeting" - Juila Child

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks