Hi, I would like to rename this thread ,Making the Quigley down under Sharps 1874 45-70 cal rifle on my lathe . Have anointed my computer with a jug of homebrew, bowed to the fore compass bearings , sniffed a bit of gun powder, that should appease the gods of wronged named threads. Feeew!, Homebrew.357.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 91 to 105 of 274

-

16-03-2015, 05:53 PM #91

-

-

16-03-2015, 06:30 PM #92

You're definitely getting a high five if I see you at the range.

-

16-03-2015, 08:47 PM #93

Hi, Tommy, Scouser , Have been to the bench rest shoots and general practice, nobody has said, Are you a rely of billy dixion. You wont see me, just look for a large cloud of smoke. I suppose I should`d do this, but it does say load development, the Asian guy with a baby a/ k look a like beside me, .223', firing like Rambo," What the hell", after my first shot with old lead poison .

Homebrew.357.

Homebrew.357.

-

17-03-2015, 08:50 PM #94

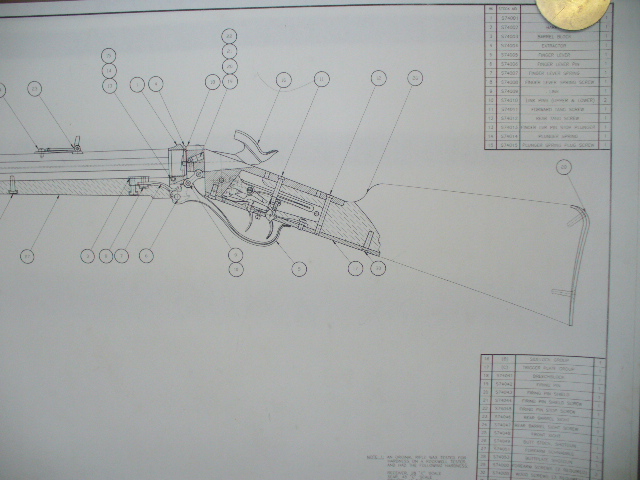

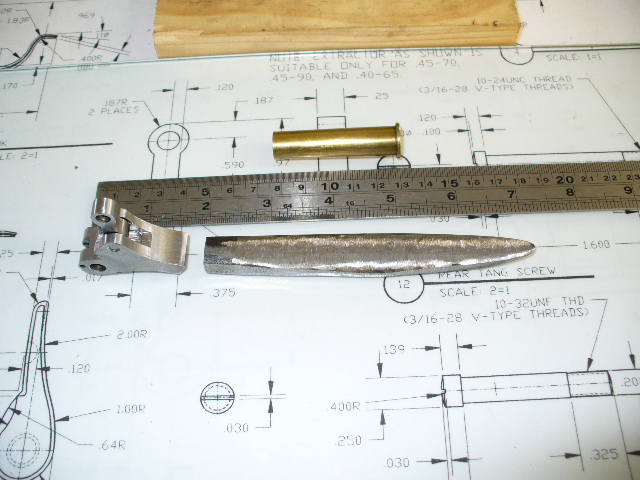

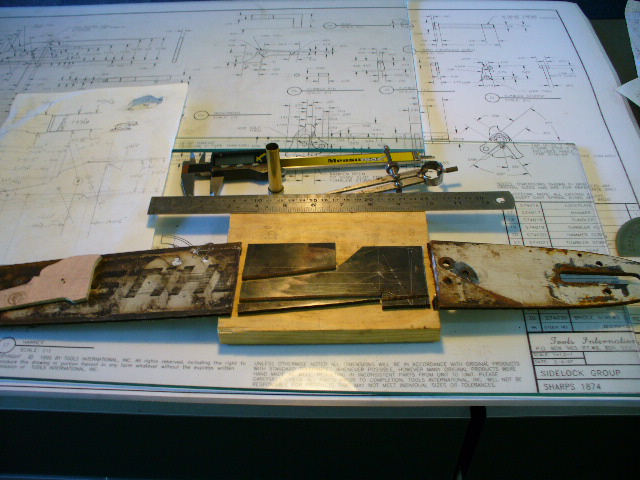

Hi all, I think I did the barrel post to show the barrel making in more detail, as I was doing it, so will go back to how I decided on the Sharps rifle for my next project. Finished the Hawken and had replenished my no 8 wire and washing machine bits, so was looking on Ebay in US when I saw Quigley down under Sharps 1874 rifle plans.

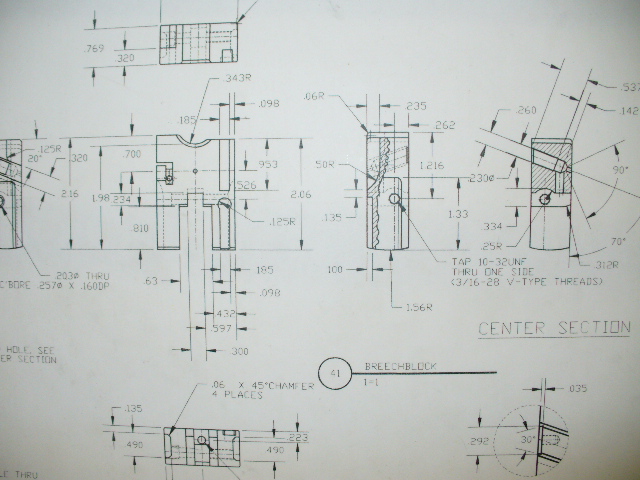

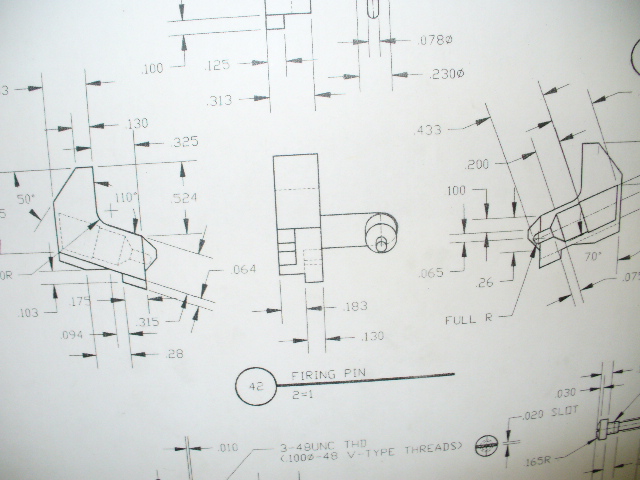

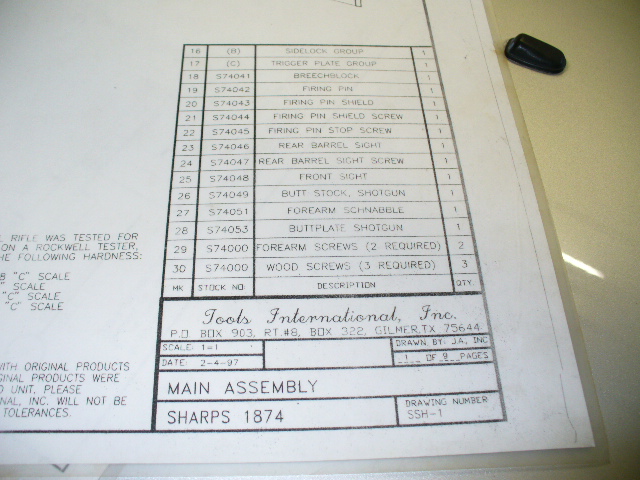

I started drooling all over the computer, after a bit of biding I got them for $65 us, +$25 pp, about nz $126.00 and on my door 5 days later. They say they for wall hanging and not for making a rifle from , do so at your own risk , I carn`t see anything wrong with then , there are 9 sheets, plans in inches, are .900mmx.640mm size and I had them lamented to keep them clean. Now this is a new ball game for me, this is the first time I have tried making from plans, yep, the Hawken had no engineering plans, just ones for making the stock. So here is some pics of the plans. Homebrew.357.

I started drooling all over the computer, after a bit of biding I got them for $65 us, +$25 pp, about nz $126.00 and on my door 5 days later. They say they for wall hanging and not for making a rifle from , do so at your own risk , I carn`t see anything wrong with then , there are 9 sheets, plans in inches, are .900mmx.640mm size and I had them lamented to keep them clean. Now this is a new ball game for me, this is the first time I have tried making from plans, yep, the Hawken had no engineering plans, just ones for making the stock. So here is some pics of the plans. Homebrew.357. , Full size.

, Full size.  ,

,  ,

, , I`m still drooling.

, I`m still drooling.

-

22-03-2015, 07:38 PM #95

Mmmmmm, I think the buggers have all gone down to the Ruapuka pub,

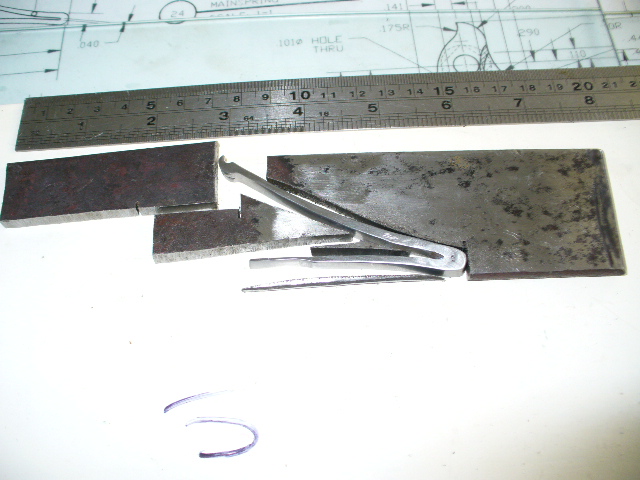

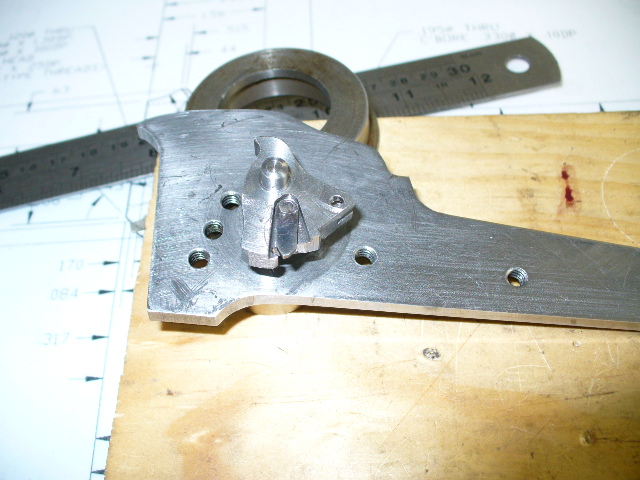

Mmmmmm, I think the buggers have all gone down to the Ruapuka pub,  . Anyway here is a #8 wire bit, the Sharps has a under lever come trigger guard thingie that drops down the breech block, so had to make it in two bits , the front part was milled, drilled, machined out of 1045 steel. The back bit was cut off the side of 1018 mild round stock, the two bits where welded together and then a lot of grinding ,sanding and polishing to clean it up and finale bent to shape . looks good. Homebrew.357.

. Anyway here is a #8 wire bit, the Sharps has a under lever come trigger guard thingie that drops down the breech block, so had to make it in two bits , the front part was milled, drilled, machined out of 1045 steel. The back bit was cut off the side of 1018 mild round stock, the two bits where welded together and then a lot of grinding ,sanding and polishing to clean it up and finale bent to shape . looks good. Homebrew.357.

,

,  , made to fit and ready for welding.

, made to fit and ready for welding. , welded.

, welded.  , bent to shape.

, bent to shape.  ,

, , with breech block.

, with breech block.

-

23-03-2015, 08:04 PM #96

But wait, there`s more,

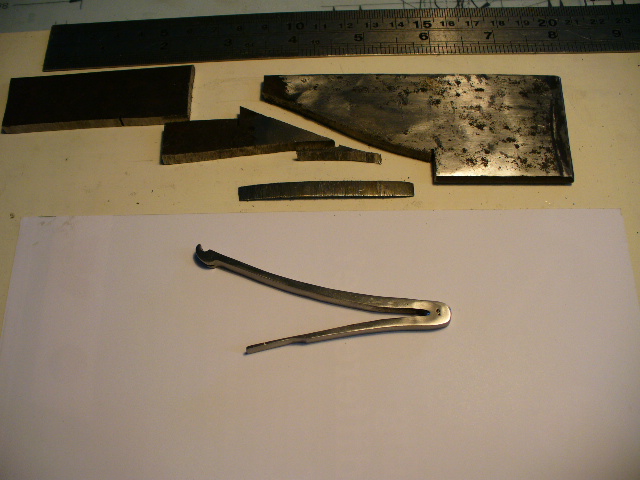

had to make the side plate with a hammer that's on steroids , also a gruntey v shaped spring to drive the hammer. Now my take on making springs is to make a spring form a spring, had a bit of car spring that had been put in the fire over night, fish it out and it`s soft to cut. Cut out the spring shape, filing, sanding to clean up smooth and then reharden it and temper, done, I had my side action main spring. Homebrew.357.

had to make the side plate with a hammer that's on steroids , also a gruntey v shaped spring to drive the hammer. Now my take on making springs is to make a spring form a spring, had a bit of car spring that had been put in the fire over night, fish it out and it`s soft to cut. Cut out the spring shape, filing, sanding to clean up smooth and then reharden it and temper, done, I had my side action main spring. Homebrew.357.

, Cut out from the lump.

, Cut out from the lump.  , Hardened, polished, tempered, done.

, Hardened, polished, tempered, done.

-

23-03-2015, 08:38 PM #97

Beautiful, your talent amazes me!

-

23-03-2015, 09:26 PM #98Member

- Join Date

- Mar 2014

- Location

- Tauranga

- Posts

- 3,033

This is so rad. I want a falling block rifle in my life

-

24-03-2015, 12:10 PM #99

Love it HB. keep up the 'great' work......

While I might not be as good as I once was, Im as good once as I ever was!

Rule 4: Identify your target beyond all doubt

-

24-03-2015, 06:06 PM #100

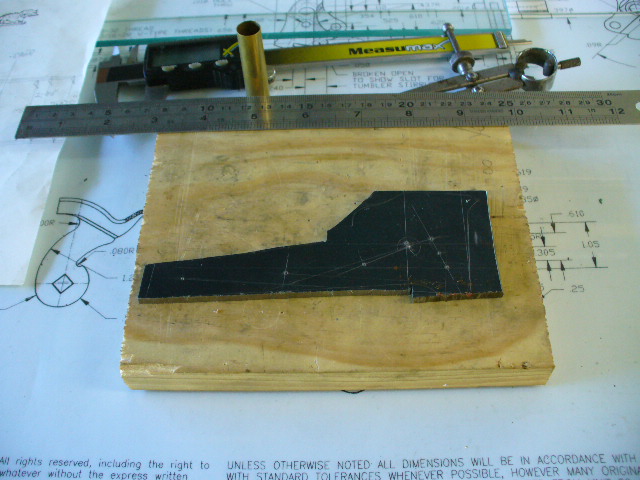

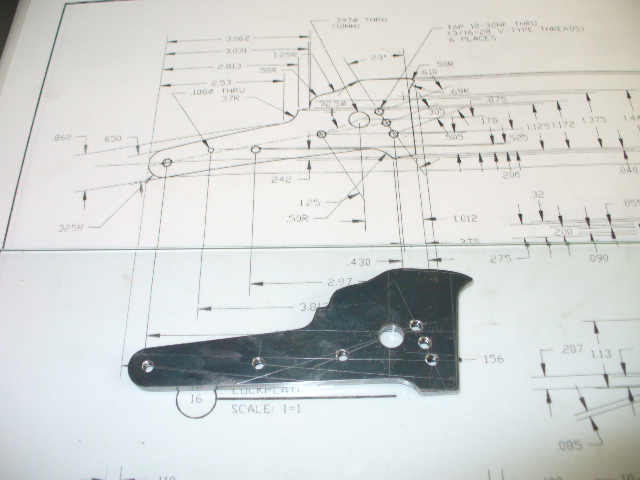

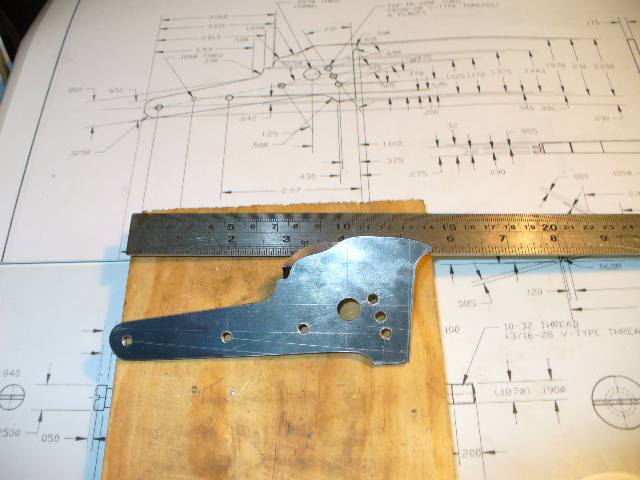

I want one to, so, I`m making it, now the action is all on a side plate and it has to be good hard steel, but you have buy a large bit and I only needed a small bit. Problem, how to find a bit of good comeinhandy stuff,

. Having a barbie at my sons place , you haven`t got some hard plate steel buy any charnce son?. I`v got three bits, buggered up Stilth chain bars, the rest is history . So cut a bit from bar with angle grinder, very hard, annealed it with gas tourch so I could cut to shape, then drilled holes and cleaned up ready for fitting other bits. So, yer, had my side plate,

. Having a barbie at my sons place , you haven`t got some hard plate steel buy any charnce son?. I`v got three bits, buggered up Stilth chain bars, the rest is history . So cut a bit from bar with angle grinder, very hard, annealed it with gas tourch so I could cut to shape, then drilled holes and cleaned up ready for fitting other bits. So, yer, had my side plate,  Homebrew.357

Homebrew.357

, Bit cut out from chain bar.

, Bit cut out from chain bar.  , Getting there.

, Getting there. , cleaned up.

, cleaned up. , The side plate from chain bar, when ready will just reharden and temper for nice finnish.

, The side plate from chain bar, when ready will just reharden and temper for nice finnish.

-

24-03-2015, 07:37 PM #101

-

25-03-2015, 05:44 PM #102

Hi, You could be right, I looked in the mirror and on my left side there`s a turret lathe, surface grinder, drill. Right side has C N C machine, shaper, lathe. Just managed to get my arms out to work on the Sharps rifle cover, a bit of Crow , Navajo bead work and it`s looking good, carn`t wait to take it to the range and pull out the Sharps 1874 Quigley 45-70 rifle and say, " You haven`t by any chance got a wooden bucket have you."

, Homebrew.357.

, Homebrew.357. ,

,  ,

,

-

27-03-2015, 03:40 PM #103

Hi it`s all coming along nicely , and making a possibles bag for my Hawken for when I can take it for a hunt, but with all the ops I`v be having will have to rethink my transport to the bush. Homebrew.357.

![Name: images[4].jpg

Views: 1205

Size: 7.7 KB](https://www.nzhuntingandshooting.co.nz/attachments/f53/35195d1427423983-making-sharps-barrel-my-lathe-images%5B4%5D.jpg)

-

27-03-2015, 07:49 PM #104

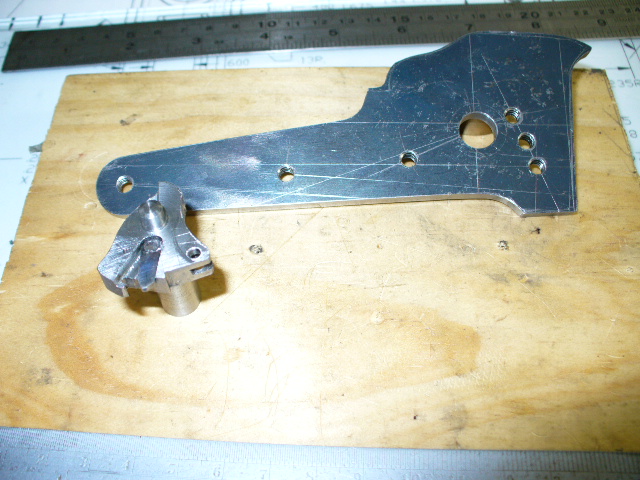

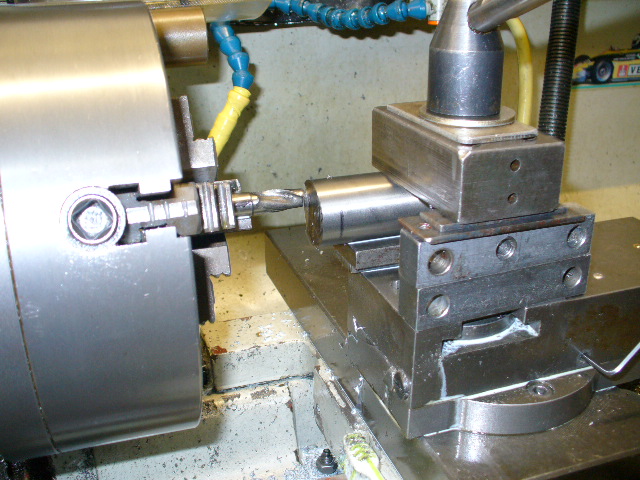

Hi again, as you proberley relies I have already made theres parts I`m showing you, I got a bit ahead. So had to make the tumbler assy with fly, it`s very much the same as my Hawken lock, but bigger. Set up round 4140 stock in lathe off centre, for the hammer shaft and machined tumbler body round, then using saddle as a shaper cut out sear and half cock notches, turned hammer and bridle shafts and then cut it of the stock, reset up to cut square for hammer. When all was polished up hardned and tempred , done!, Homebrew.357.

Hi again, as you proberley relies I have already made theres parts I`m showing you, I got a bit ahead. So had to make the tumbler assy with fly, it`s very much the same as my Hawken lock, but bigger. Set up round 4140 stock in lathe off centre, for the hammer shaft and machined tumbler body round, then using saddle as a shaper cut out sear and half cock notches, turned hammer and bridle shafts and then cut it of the stock, reset up to cut square for hammer. When all was polished up hardned and tempred , done!, Homebrew.357.

,Turning to shape.

,Turning to shape.  ,coming on.

,coming on.  ,

, bit more work.

bit more work.  , cutting the sear.

, cutting the sear.

-

27-03-2015, 10:47 PM #105Member

- Join Date

- Dec 2012

- Location

- Dunedin

- Posts

- 589

If you need more dead chainsaw bars give me a shout I have about 20 or so here.

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks