Hell no, I don`t want any more, still got one large one, this is my last rifle build and will take a while yet to do. Thought I would make it nice on the in side, so had a go at jeweling it, passable . Now the next bit is how do you make a Sharps side hammer on a lathe., Homebrew.357.

, Looks good.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 106 to 120 of 274

-

29-03-2015, 10:31 AM #106

-

-

30-03-2015, 07:48 PM #107

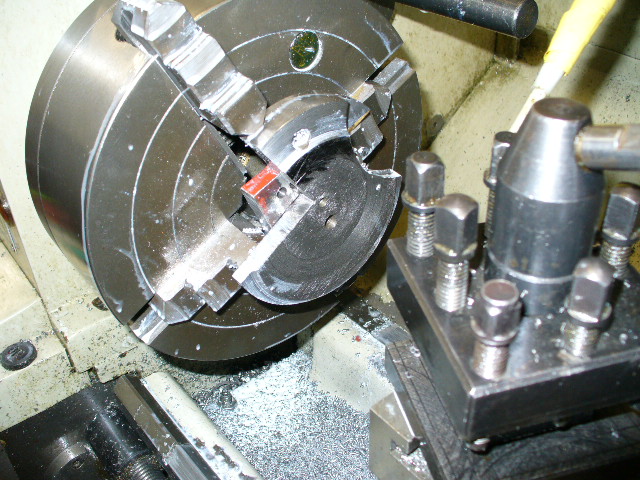

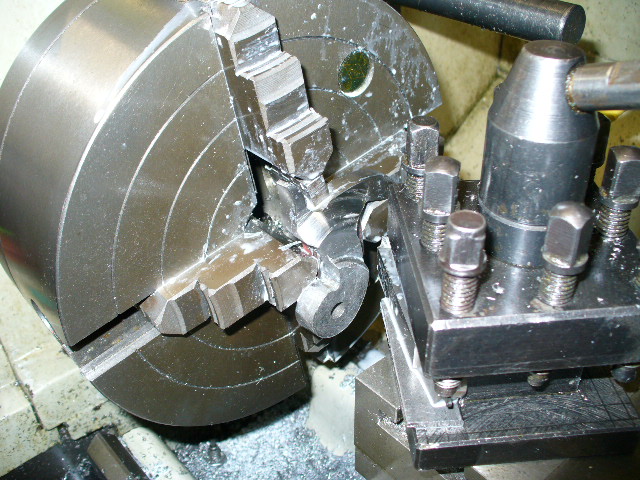

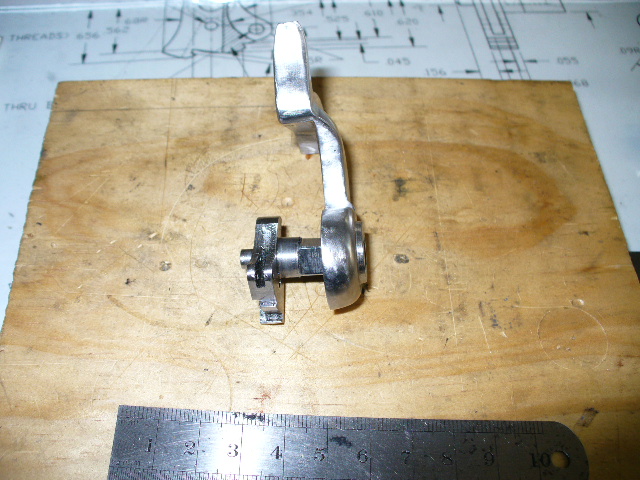

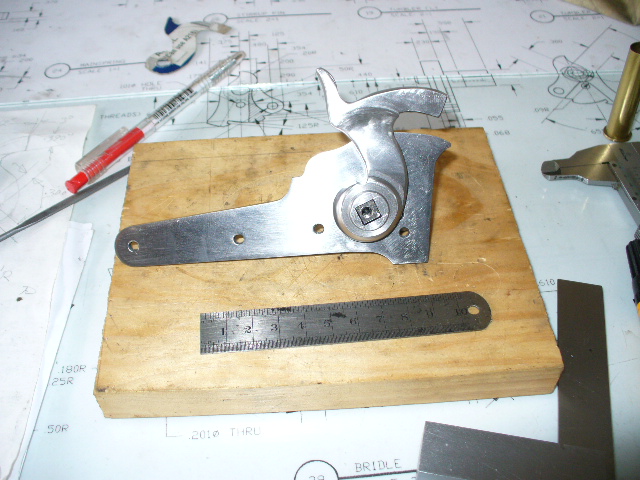

Now the hammer was a bit of a mission, I had a large round bit of 1045, so this was going to be the hammer, set up and faced it clean then drilled some datum holes. The hammer head over left at the top, so had to cut all the rest off to allow for this, then cut a bit more or the hammer sharp. On the right side a radius was cut with a formed tool and was cut with the old rock and roll with the chuck , could not be turned . So that's the start of the hammer,

.Homebrew.357.

.Homebrew.357.

, Large bit of steel.

, Large bit of steel.  , Set up to mill heaps of along the black mark.

, Set up to mill heaps of along the black mark.  , profile cut, rock and roll.

, profile cut, rock and roll.  ,Hammer coming out, more hacksawing.

,Hammer coming out, more hacksawing.  , cutting hammer profile, R/Roll.

, cutting hammer profile, R/Roll.  , getting there.

, getting there.  , Starting to look like a hammer.

, Starting to look like a hammer.

-

31-03-2015, 11:45 AM #108

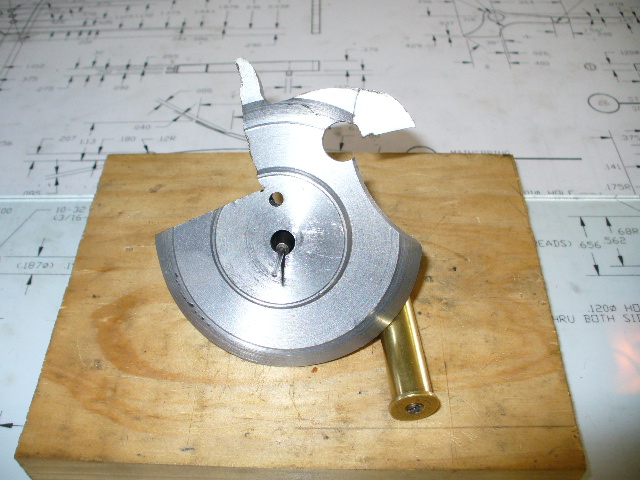

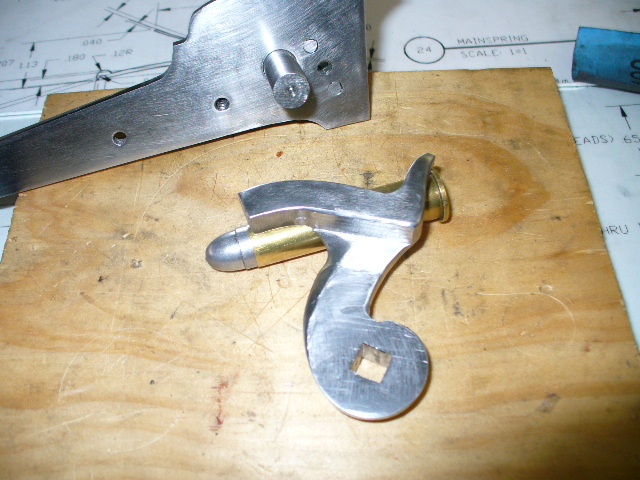

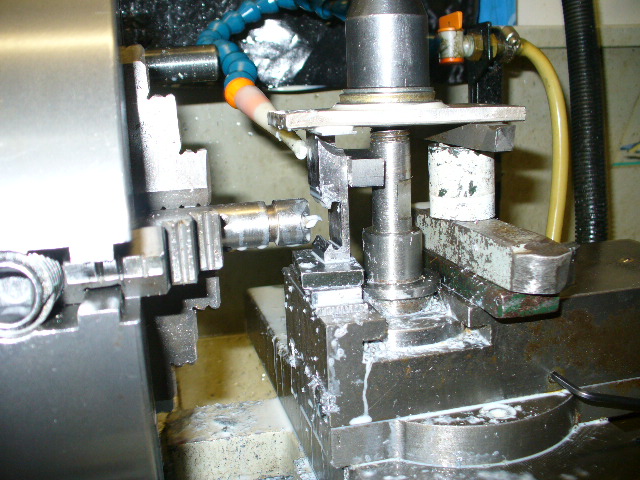

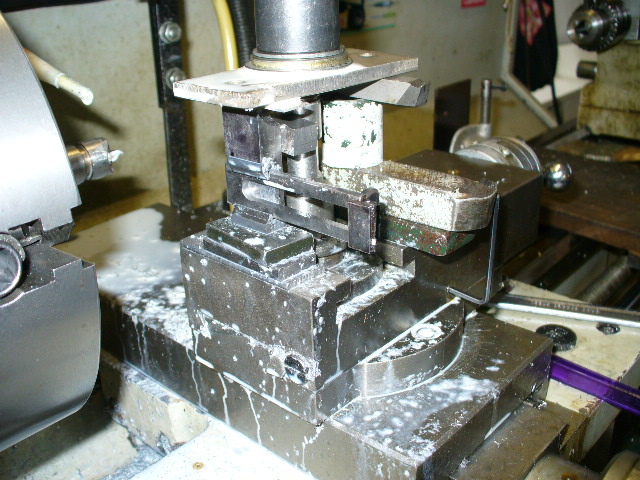

Hi, The hammer had to have a square hole at just the right angle to line up with the tumblers square shaft for half cock and full cock. I did this by using the saddle as a shaper to square the hammers round hole, and same for the tumbler shaft, when the hammer was just starting to go on the tumbler shaft I finished with fine files. Had to thin down the main spring, to hard to cock, I made it thicker so I could take some off to get it right , and I had my Sharps side plate all good to go.

Homebrew.357.

Homebrew.357.

, Hole square.

, Hole square.  , Bingo, a Sharps hammer on steroids.

, Bingo, a Sharps hammer on steroids.  , Tumbler shaft cut square.

, Tumbler shaft cut square.  ,The set up.

,The set up.

-

31-03-2015, 12:41 PM #109

Brilliant HB....classic mate!!!!

While I might not be as good as I once was, Im as good once as I ever was!

Rule 4: Identify your target beyond all doubt

-

31-03-2015, 07:14 PM #110

The last bit is also good, I`m rapt my self . Shaft fits hammer snug, with a press fit, then assembled it all and got it working to full cock, so I now have a complete working Sharps side lock, will need final fitting to the action,

, Hombrew.357.

, Hombrew.357.

,

,  , press fit.

, press fit.  , fits on nice.

, fits on nice.  , all fits.

, all fits.  ,at full cock, and made the hammer screw to.

,at full cock, and made the hammer screw to. , the other side.

, the other side.

Last edited by homebrew.357; 31-03-2015 at 07:26 PM.

-

31-03-2015, 07:27 PM #111

-

31-03-2015, 07:36 PM #112

Now what I need is a nice bison seine ingraved on the side plate, have to find out how/ who to do it. Hey, off the crutches and working on my hip. Homebrew.357.

-

31-03-2015, 07:44 PM #113

Get an engraver and teach yourself!

VIVA LA HOWA

-

31-03-2015, 08:05 PM #114

Oops, I must be getting old brained, I just found I have posted all this on Making a Sharps rifle on my lathe, are well you are getting double , and I had better check around, maybe I`m making two guns!,

Homebrew.357.

Homebrew.357.

-

03-04-2015, 08:29 PM #115

Hi, hips ok, but now have had a huniea op, right side, so back to resting up for a bit, will get things going when I can get out and about.

Homebrew.357.

Homebrew.357. , cover for the Sharps.

, cover for the Sharps.

-

05-04-2015, 11:56 AM #116

And put the finishing touches to my possibles bag and have made a ali hunting ram rod ,so all`s ready for when I can get out and about. When I have got the barrel and action together will need a kind farmer/ land owner out of Auckland who, my have his own rifle range to proof test the Sharps, (try to blow it up), but will be a while yet. Could be a few bottles of homebrew!,

. Homebrew.357.

. Homebrew.357.

-

06-05-2015, 09:33 PM #117

Well that went down like a lead balloon, so nobody has a 200,000 tho farm, well will just have to get down to the bush in my caravan for a hunting, gun testing 5 day trip. Have looked at getting the receiver breech block hole cut out with wire E D M, all`s looking good, going back Friday with all the plans and bits so I can get things up and running again. Speaking of running, no I`m walking, the hip is coming along nicely , going for long walks to wear it in. Have not been to the nzda range for a bit, I see a black powder cannon shoot coming up , so will give old lead poison a work out.

Cheers, homebrew.357.

Cheers, homebrew.357.

-

07-05-2015, 06:36 PM #118Member

- Join Date

- Aug 2014

- Location

- wairarapa.

- Posts

- 75

you are a bloody legend and a national treasure Homebrew

-

09-05-2015, 08:08 PM #119

Hell, I don`t think I`m that good, but will be happy when I feel the recoil and see the smoke from the first shot at the range and as they say, "It`s not over till the fat lady sings", which means the gun is not finished yet. So still working on bits for the Sharps like the back sight, set up on the lathe to mill out the range slider on the pop up for long range shooting. Would also love a tang peep sight, so will look at that a bit later, quite a tricky bit to make, but as my grand son say`s, "grandad can fix anything, he even made a GUN!.

Homebrew.357.

Homebrew.357.  , Milling machine at work.

, Milling machine at work.  , Making the slider.

, Making the slider.  , In the rough, but getting there.

, In the rough, but getting there.

-

18-05-2015, 08:46 PM #120

Hi, Have sent the block of 4140 steel for the receiver to cut out the breech block hole, should hear back soon when finished. Went to the black powder shoot and after lunch had a go with my Hawken, .45, well getting all ready to load and hammer to half cock, no spring load, the tumbler to spring pin had come out,

, so a frantic side plate out, pin back in and pliers to hook spring back on. Had my best group with ten shots, fore holes touching ,

, so a frantic side plate out, pin back in and pliers to hook spring back on. Had my best group with ten shots, fore holes touching , . The sight is finished and looks good, Homebrew.357.

. The sight is finished and looks good, Homebrew.357.

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks