Hi Everyone,

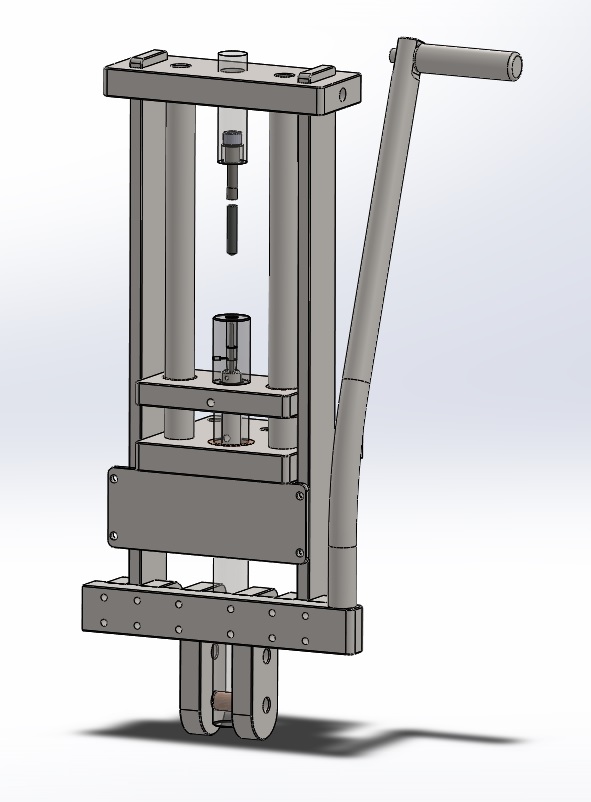

I have started work on building a swaging press over the last few days.

Based on this idea here Lets make a Swage press

I have always wanted to play around with swaged bullets and I have a couple of projects on the go that I want to make some heavy for caliber lead projectiles for.

I may also have a go at making .223 projectiles from 22lr brass but I already have a few thousand 62gr projectiles so probably wont for a while.

My main plan is to use it to make unusual projectiles I cant otherwise buy. For example a 9mm 250gr flat nose bore rider so it can be chambered in a standard .357 Sig chamber and not have to be seated deep into the case.

I have experimented with making the dies and have been somewhat successful, so now that I know I will be able to make dies for it, Im making a press.

This thing is all heavy steel and is about at the limit of what my machines can handle easily, I started cutting everything to rough size a while ago and have since moved house and setup a new workshop.

Im using Chinesium hardened ground shafting for the guide rods and a length of 4140 steel purchased from Homebrew.357 for the central ram.

It turns out the shafting is not hardened at all, which actually makes my job easier.

Only just fits in the bandsaw. I had to flip it over to get the whole way through and use a small fan to cool the motor.

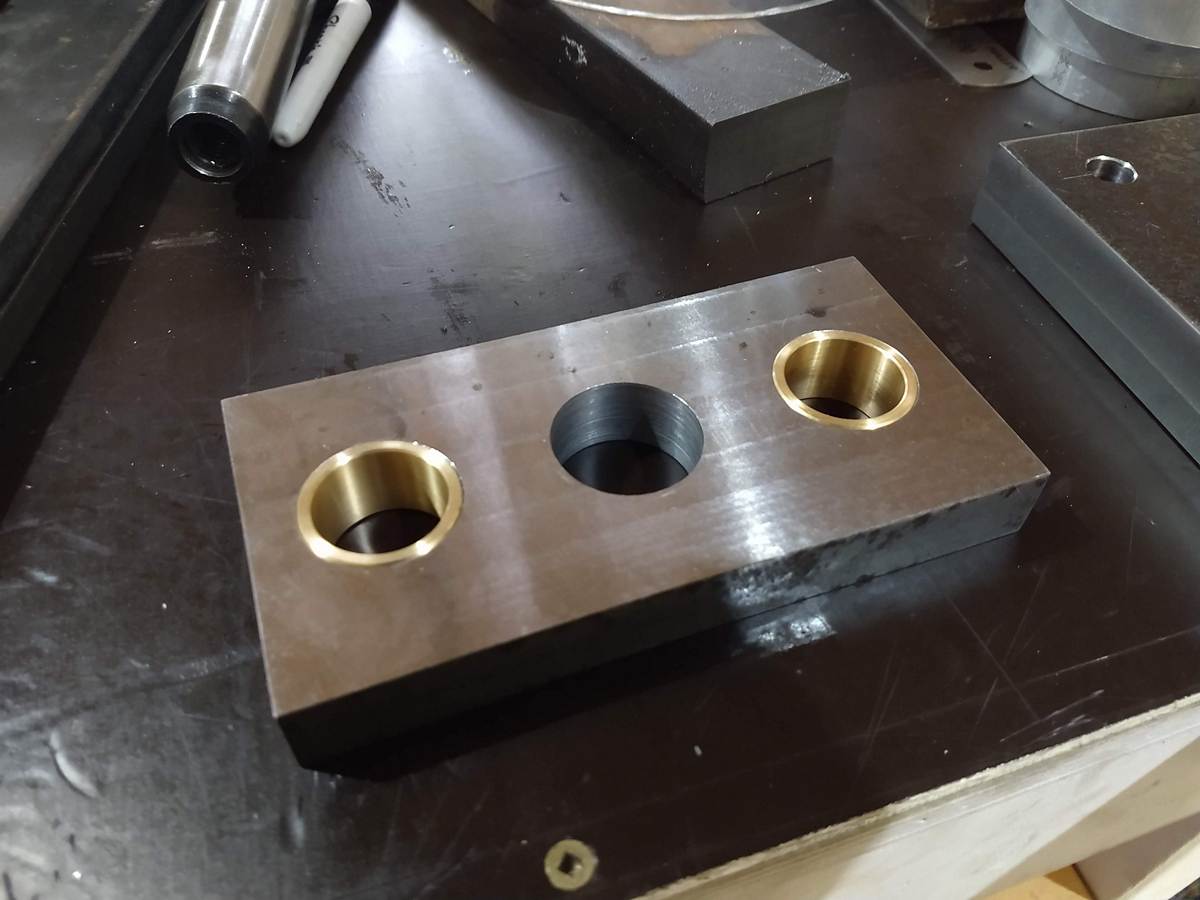

I made the top and bottom plates and drilled and tapped each end of the guide rods and did a quick assembly

I was planning to use proper bronze bushes but it was going to add up to about $120 for what I needed. Then corona happened and im working on this in lockdown, so I decided to just make the bushes from brass i can always replace them if they wear out in the future.

Ill keep you all updated.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 10 of 10

Thread: Making a Swaging Press

Threaded View

-

15-04-2020, 10:37 AM #1

Making a Swaging Press

Similar Threads

-

New bullets - swaging

By xring in forum Firearms, Optics and AccessoriesReplies: 14Last Post: 15-01-2014, 10:47 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks