Another double rifle day

Turned some barrels in the wood lathe to try and sort profiles and start on the ribs while the barrels are being made.

Also a good template for the barrel makers copy lathe

I guess I should paint them black

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 256 to 270 of 347

Thread: Self isolation gun projects

-

11-05-2020, 05:26 PM #256Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,942

-

-

11-05-2020, 08:15 PM #257

They’re not parallel taper are they?

Sent from my iPhone using Tapatalk

-

11-05-2020, 09:02 PM #258Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,942

-

11-05-2020, 09:18 PM #259northdudeGuest

probably wooden work very well

-

12-05-2020, 12:05 AM #260Member

- Join Date

- Jan 2017

- Location

- Waiuku

- Posts

- 852

In steel that looks heavy, I hope the hole is big. Is it worth trying to work out the voume of your wooden mock ups from which the weight could be worked out?. Not to hard to work out how much water each barrel displaces.

-

12-05-2020, 09:03 AM #261Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,942

-

12-05-2020, 10:51 AM #262Member

- Join Date

- Dec 2017

- Location

- Scotland

- Posts

- 127

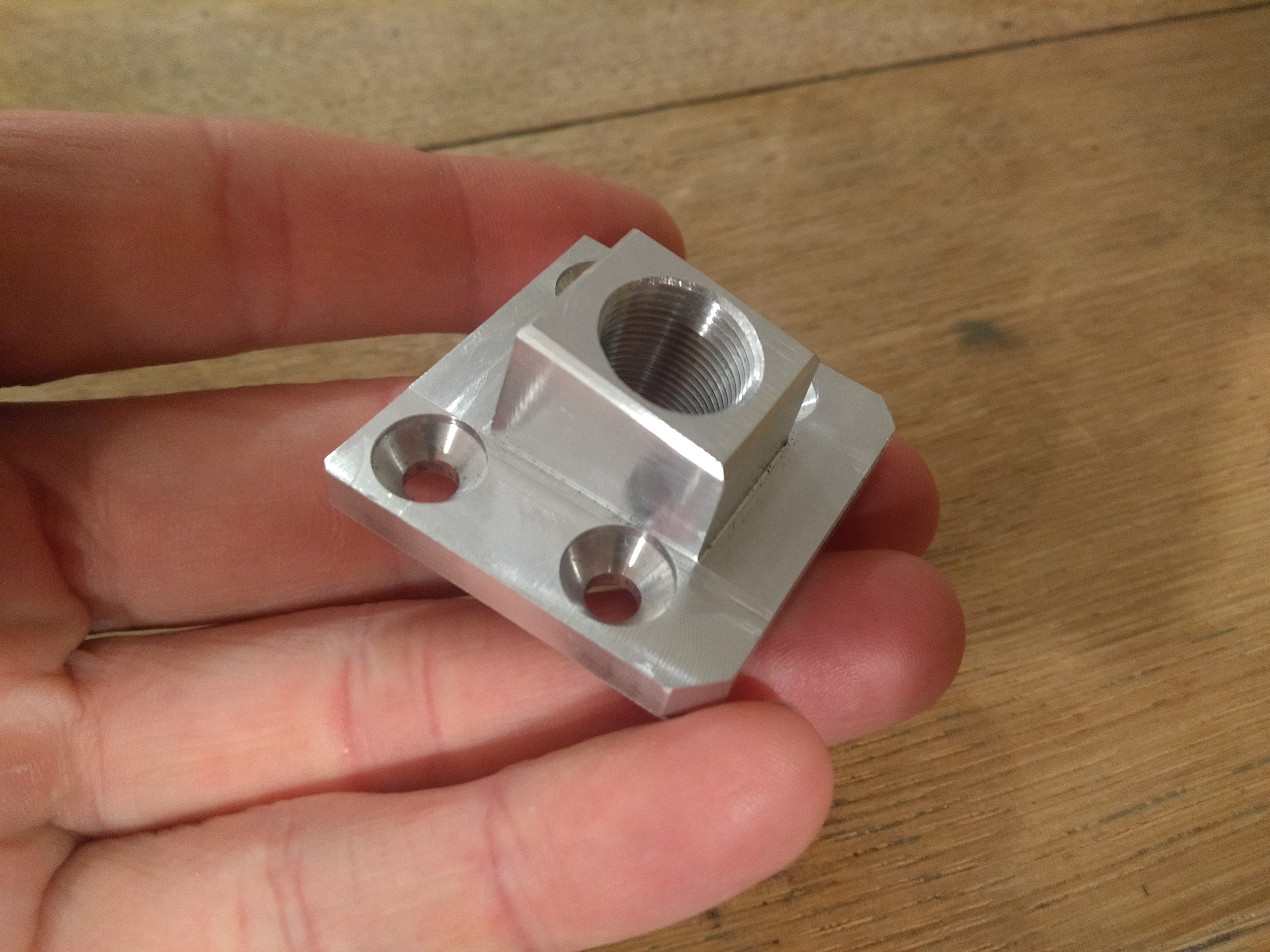

Made a stock hanger for my De Haas project this afternoon.

I'm halfway through a CF stock for my Sako.

Also, my first prototype of a Steyr SSG69 mag housing that I reverse engineered for a guy on our UK stalking forum has turned out way better than I expected.

-

15-05-2020, 06:42 PM #263Member

- Join Date

- Jan 2015

- Location

- Wellington

- Posts

- 2,727

-

15-05-2020, 07:53 PM #264Member

- Join Date

- Feb 2018

- Location

- Waikato

- Posts

- 1,358

Thank you to you clever buggers posting up your work, really appreciate you going to the trouble to photograph & post, plus do those cool projects !!

Awesome !

-

16-05-2020, 01:32 AM #265Member

- Join Date

- Dec 2017

- Location

- Scotland

- Posts

- 127

Well, I'll keep posting here since we're still in lockdown here in Scotland and I've got another 2 weeks of furlough from work...

My first successful carbon fibre stock. Made plenty mistakes and learn a lot each time I mould stuff. It's coming in at 736g and feels really stiff so am pretty chuffed with it. I'll bed it over the weekend and paint it next week with 2 pack polyurethane paint.

-

20-05-2020, 01:50 PM #266Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,942

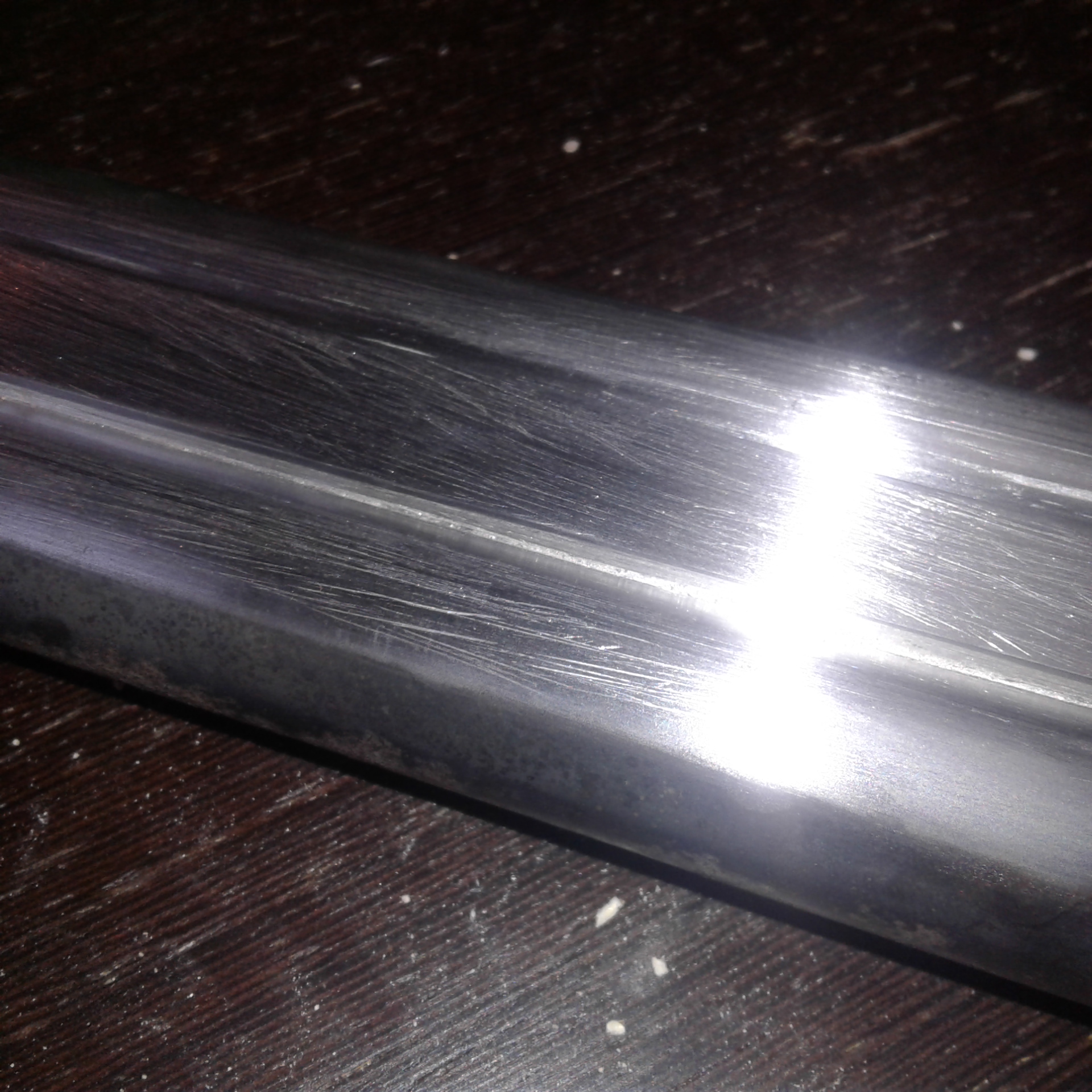

I have been chipping away at my double rifle project.

That will still be going for the next pandemic

But I have been matching a pile of castings and doing drive wheels and shafts for a high precision 2" wide belt linisher

It will be for finishing small gun parts

I still need to fabricate a spring tensioner for the top arm

Fit the table and belt backing plate

Scrounge a 1/2 hp motor and get it swinging at about 3000 rpm

The battery drill can run it at 1200 rpm to test the tracking and wheel alignment

-

20-05-2020, 09:34 PM #267Member

- Join Date

- Dec 2017

- Location

- Scotland

- Posts

- 127

And it's complete - painted matte OD Green and tipping the scales at 750g.

-

25-05-2020, 01:51 PM #268Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,942

Got some silver solder and non corrosive flux in hand

So did my first laying top rib test piece

Can only improve with practice.

Certainly nice and strong and can't get it off

-

25-05-2020, 03:32 PM #269Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,942

And a curved top rib test

Went better than the flat one

Lots to learn

-

25-05-2020, 06:42 PM #270Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,942

And then I milled the heavy flat rib to a nice curve and think i have found what will work when I do the double rifle barrels

Similar Threads

-

My projects last 12 months!

By Gloves in forum Projects and Home BuildsReplies: 7Last Post: 21-07-2018, 06:06 PM -

DIY Leather Projects

By LOC in forum Projects and Home BuildsReplies: 22Last Post: 25-01-2017, 06:33 PM -

Dog projects

By RCGSP in forum Trial, Pedigree and Bird DogsReplies: 35Last Post: 18-06-2013, 09:12 PM -

Dog projects

By RCGSP in forum DogsReplies: 21Last Post: 09-01-2013, 01:15 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

697Likes

697Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks