Gave the howa mini a wee paint job, was going to go Matt black but liked the grey primer coat so just gave it a few more. Just a subtle wee change from the stainless

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 286 to 300 of 347

Thread: Self isolation gun projects

-

21-08-2021, 12:07 PM #286Member

- Join Date

- May 2020

- Location

- Gore

- Posts

- 170

-

-

21-08-2021, 03:32 PM #287Member

- Join Date

- Jul 2013

- Location

- Waikato

- Posts

- 2,610

Wouldn’t leave it just as primer,might need a clear coat over the top ,found my paint job on the sako rubbed off at the carry spots,oils from your hands affect the primer.I used a black etch primer on my stainless barrel and it hasn’t worn off where as camo top coats have.

-

21-08-2021, 05:04 PM #288Member

- Join Date

- May 2020

- Location

- Gore

- Posts

- 170

I am going to leave as is and see how it goes, I did a 10/22 barrel couple years ago with this and was going to put a top coat bit ended up wanting to go shooting so left it and never went back to finish it and it has withstood really well. Be interesting to see as 10/22 was bead blasted first so better prep.worst case is it scratches/peels off and I'll have to redo at some stage.so your camo top coats wore off down to your etch primer or did you just have a etch primer on?

-

21-08-2021, 08:36 PM #289

Decided to make a benchrest and used it today to check the sighting on that JW15. The butt rest is moveable to accommodate different length rifles.

Now discovered though that I need to angle cut those outside top corners of the butt rest as they dig into you.

-

21-08-2021, 08:47 PM #290Member

- Join Date

- Jul 2013

- Location

- Waikato

- Posts

- 2,610

-

23-08-2021, 05:29 PM #291

Finished this a while ago, but lockdown finally got me to post about it.

Decided I wanted some front and rear sights for a single shot rifle but didn’t have enough time to do it in the workshop, so modelled it with 5 minutes here and there and then printed it instead.

Ultimately these were to test the idea and adjust rather than a finished product, but they worked out really well. Great way to prototype stuff or just make something tough and lightweight quickly.

Front sight is a keyed insert so you can change it out as you want – the triangular profile was made to be filed down for testing but ended up not needing to file. Next version would be carbon fibre for rigidity and have a fibre optic insert for low light.

Rear sight is elevation adjustable with a through-drilled hex head screw and nut assembly. I pressed a disk onto the head of the screw to block the right a bit better. Printed the rail too just for fun – A carbon fibre rail would actually work quite well. In the future I’ll probably either make the rear sight a clamp-on unit or built it into the rail so it can fold away when not in use and not interfere with a scope.

-

23-08-2021, 07:34 PM #292Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,942

-

23-08-2021, 10:27 PM #293Member

- Join Date

- Aug 2019

- Location

- South Otago

- Posts

- 4,011

Made a foresight for my Italian slug pistol, attached it with JB Weld. (I’d made a rear sight and foresight a while ago but somehow lost the foresight)

Looks good - only I found out it shoots 8 inches high at 10 metres even with the rear sight at lowest setting

I guess the previous foresight was a tad higher…‘Many of my bullets have died in vain’

-

23-08-2021, 10:28 PM #294

Slightly envious of the guys for who lockdown gives them extra project time - no such luck here. Still, managed to pull this together on Sunday:

It's a jig for hollowpointing .22 target ammo into better subsonic hunting ammo. Not that I strictly needed one, but it occurred to me that I happened to already have almost everything I needed: collet block with ER25 6mm collet, mill/drill as a press, and a 60deg carbide dead centre. I turned up the stand/guide from 303 stainless. Assembly works like this:

1) Clamp the stand in the mill vise. The base is cut perpendicular and I already know my vise ways are flat and square, so it doesn't need further aligning.

2) Using a centre finder, centre the mill quill over top of the stand. Insert dead centre. Zero mill height readout with tip of centre touching top of stand, then retract out of the way.

3) Place .22 round in the recess in the top of the stand.

4) Lower collet block (collet adjusted loose) over top of the .22 round and the stand. The stand is turned to be a close slip fit for the bore of the collet block and it all self aligns before the bullet nose starts entering the collet. Snug collet by hand (witness marked to make it repeatable.) The tip of the bullet only slightly protrudes from the top of the collet so the bullet driving bands are fully supported.

5) Lower quill to desired depth; pressing the centre into the nose of the bullet.

6) Retract quill, slightly loosen collet, lift collet block off guide and remove modified round (drops free with a light tap of the fingers).

7) Repeat steps 3-6. Takes about 35s a round, but it would be quicker if I made up a hard depth stop instead of creeping up using the DRO.

I've made up 5 test rounds each of 2.0mm, 2.5mm and 3.0mm HP depth (2.5mm pictured) from the RWS Target Rifle 40gr my Voere likes. Looking forward to testing them for grouping after lockdown, but I'd be surprised if the accuracy suffered much. That 3.0mm HP sure looks nasty...

-

23-08-2021, 10:31 PM #295Member

- Join Date

- Jul 2012

- Location

- Invervegas

- Posts

- 5,699

New Property. We're supposed to be building a shed and house but . . . bloody engineers

So today I attended to priorities - built a new backstop for the 22 range, we're pretty much surrounded by "reserve" so shooting a suppressed 22 is a luxury I like to indulge!

![Name: 20210823_170540[1].jpg

Views: 514

Size: 4.38 MB](https://www.nzhuntingandshooting.co.nz/attachments/f53/176013d1629710975-self-isolation-gun-projects-20210823_170540%5B1%5D.jpg)

Will be able to shoot 50M from the new deck. 100M from within the property. Out to 240M with the goodwill of the grazier of the reserve - thats heaps for a 22!

-

24-08-2021, 08:23 PM #296

Ran out of epoxy yesterday which has stalled my Tikka CF stock project, however I had this Marlin stock project that needed dremelling to inlet that I hadn't attacked for a while. Used a bit of Kevlar material in this stock. Quite different to work compared with CF.

Need to inlet the forend tomorrow. Thinking of making it a one piece unit with an incorporated CF feedtube."That is ever the way of the Highlander. He alters like a clear pool to every mood of the sky, so that the shallow observer knows not how deep the waters are."

-

29-08-2021, 12:18 AM #297Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,942

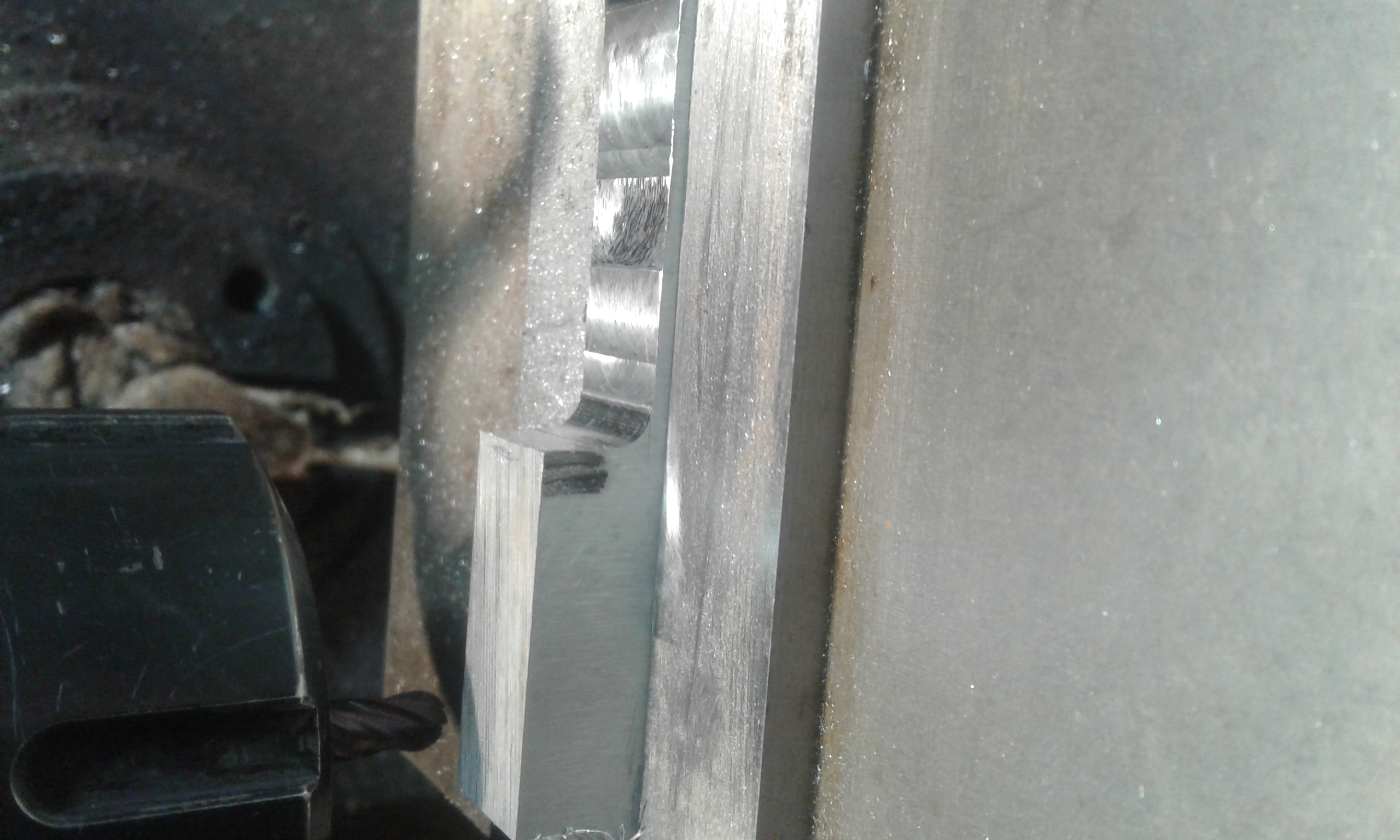

One last burst in the workshop before I go back to work at level 3

A very custom scope mounting rail

Quite a lot of machining doing the top side

Tomorrow the barrel profile and taper to do on the bottom

-

29-08-2021, 10:56 AM #298

we did this crudely for years before powerpoint was made by winchester...it will make hollow point rounds stop inside body of hare or possum with chest shot 90% of the time,we gave up shooting possums in the head and simple chest shot them in the V of the throat patch....seldom exited between shoulder blades..... awesome job you have done,look forward to seeing how the preform.

-

29-08-2021, 01:42 PM #299

Thanks, will put up a follow-up post after I've had a chance to test.

-

29-08-2021, 04:59 PM #300Member

- Join Date

- Jul 2012

- Location

- Invervegas

- Posts

- 5,699

My portable shooting bench (takes down to "flat") worked pretty good but I'm always looking for improvements . . .

So in the past the shooter sat on a separate stool, but I got to thinking and looking at other designs that if the seat was connected to the bench the shooters weight could contribute to stability.

An afternoons work with some basic tools( poor old jigsaw which gave its last gasp for this job, I think my old Dad who has since passed gave me it as "very used" about 10 years ago), some ply that was lying about and a wee bit of swearing, produced this:

![Name: 20210829_153010[1].jpg

Views: 302

Size: 4.46 MB](https://www.nzhuntingandshooting.co.nz/attachments/f53/176874d1630209436-self-isolation-gun-projects-20210829_153010%5B1%5D.jpg)

The seat adds considerable stability to the bench, I'd rate it about 95% of a concrete one now.

Similar Threads

-

My projects last 12 months!

By Gloves in forum Projects and Home BuildsReplies: 7Last Post: 21-07-2018, 06:06 PM -

DIY Leather Projects

By LOC in forum Projects and Home BuildsReplies: 22Last Post: 25-01-2017, 06:33 PM -

Dog projects

By RCGSP in forum Trial, Pedigree and Bird DogsReplies: 35Last Post: 18-06-2013, 09:12 PM -

Dog projects

By RCGSP in forum DogsReplies: 21Last Post: 09-01-2013, 01:15 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

697Likes

697Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks