Thanks, It is pretty fun doing it. I wish I had some checkering tools or something to work on it a bit more.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 96

Hybrid View

-

28-09-2012, 10:41 PM #1

-

28-09-2012, 10:43 PM #2

I'm lovin' the borer holes in that old chisel handle, I've got an old wooden scriber with holes like that, proper stuff!

Ray.10MRT shooters do it 60 times, in two directions and at two speeds.

-

08-08-2013, 05:51 PM #3Member

- Join Date

- May 2012

- Location

- Far North

- Posts

- 4,883

Custom leupold turret system by fuller

-

08-08-2013, 06:06 PM #4

Jeez Bill, that would almost double the weight of the scope! A+ for ingenuity though!

Hunting is not a hobby.....its an addiction

Hunting is not a hobby.....its an addiction

-

08-08-2013, 07:56 PM #5Member

- Join Date

- May 2012

- Location

- Far North

- Posts

- 4,883

haha yea surprised how well it works

will help me decide weather i can be botherd sending it to leupold

-

08-06-2014, 12:42 PM #6

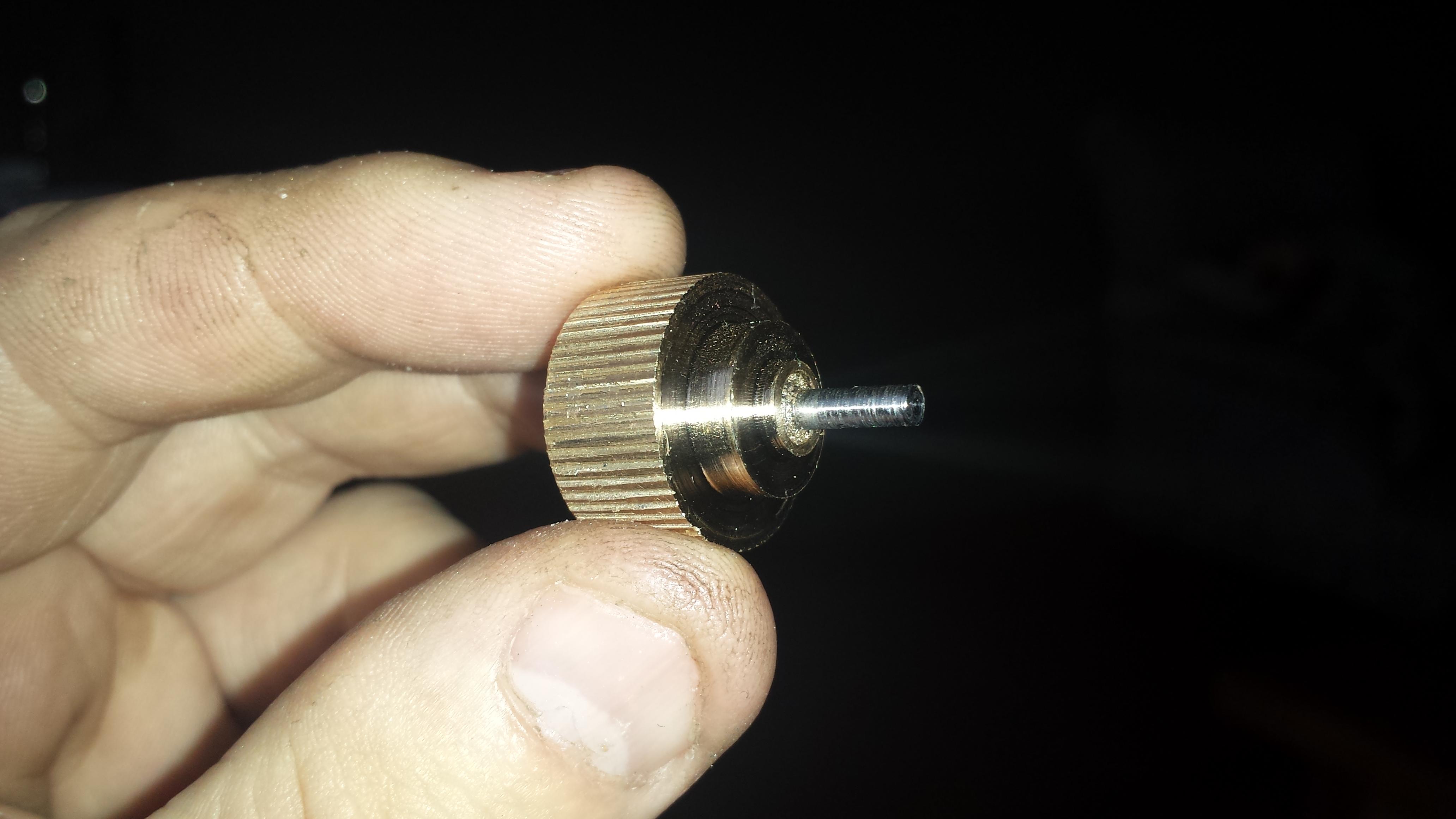

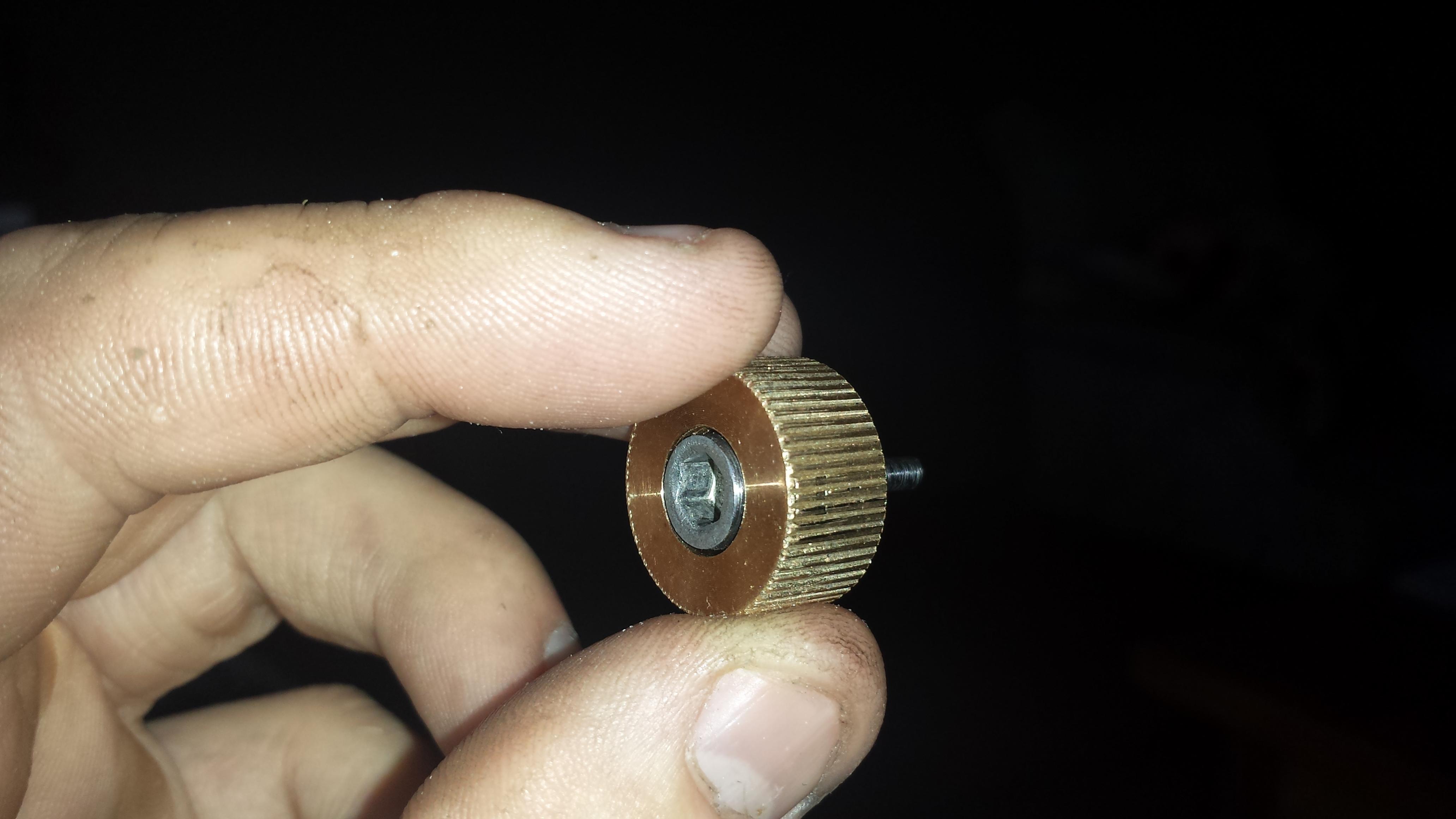

ok , so not quite "gunsmithing " .... but more magazine related ...I have a gsg.22 semit auto with 10 shot mags .... to reload them is a little fiddly and if you don't have finger nails like me ... you need a little help , saw this on the net , so thought I would make one , .... small tool , but took a stupid amount of time , .... it gets put into a hole in the magazine follower so you can use you thumb to pull down the spring and just drop the rounds in ..... if you use your thumb to load at the range , all you can think about while aiming is your stinkin sore thumb .... hope the pics load ...

NO MATTER HOW MUCH IT HURTS, HOW DARK IT GETS OR HOW FAR YOU FALL , .....

NO MATTER HOW MUCH IT HURTS, HOW DARK IT GETS OR HOW FAR YOU FALL , .....

YOU ARE NEVER OUT OF THE FIGHT . (Marcus Luttrell)

-

30-12-2014, 11:59 AM #7

with me giving up farming soon and heading back to the workshop what better time to give the 8x57 a few mods.

after stripping down the action just getting to the point of sweating the rear sight mount off

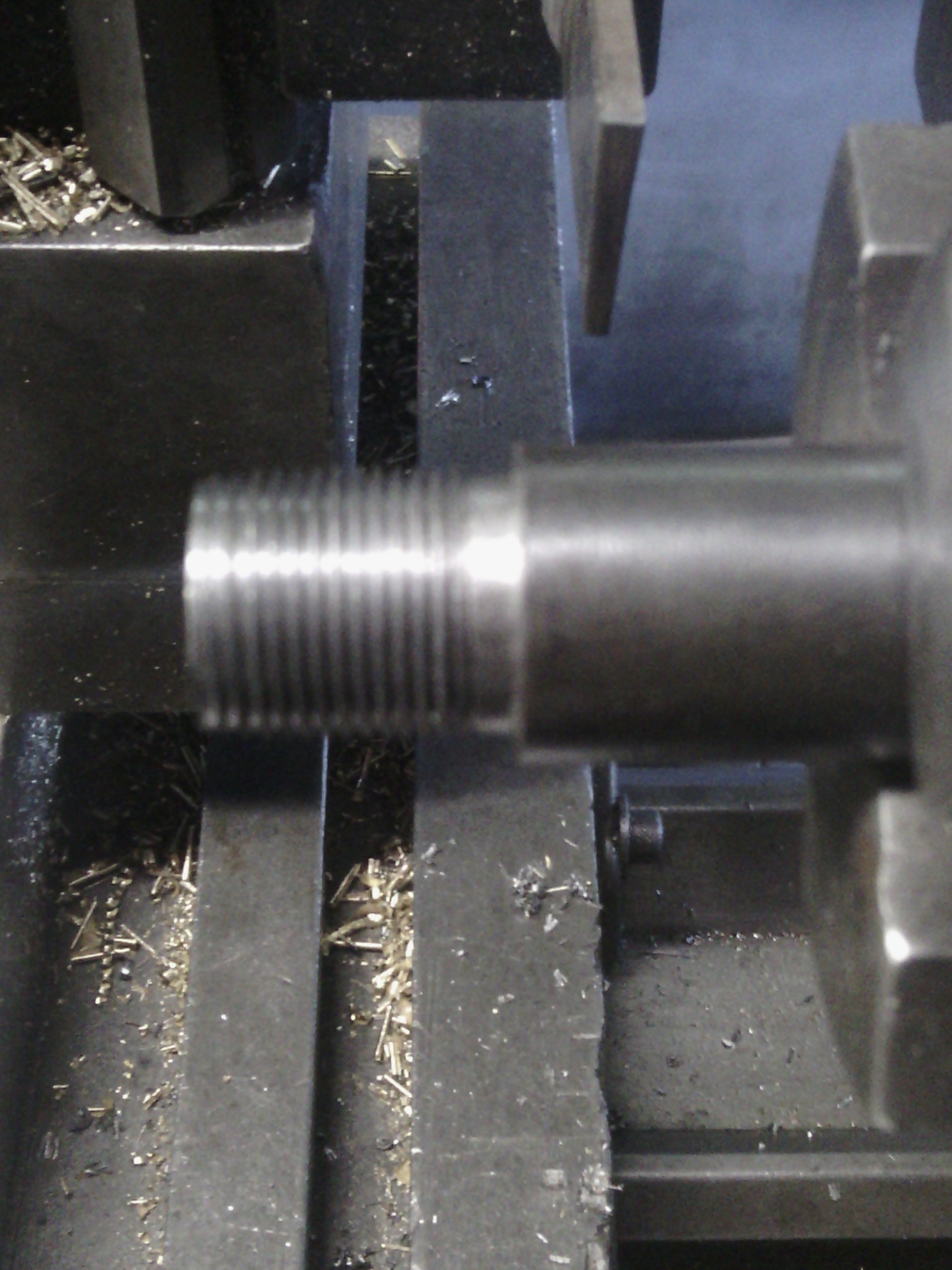

after stripping down the action just getting to the point of sweating the rear sight mount off at this point the barrel has had a 100mm chop just about to machine down to 14mm for the thread cut and using the first step in the barrel to square off on.

at this point the barrel has had a 100mm chop just about to machine down to 14mm for the thread cut and using the first step in the barrel to square off on. a bit blurry but a quick shot of the threaded end ready to make end cap

a bit blurry but a quick shot of the threaded end ready to make end cap

after a bit of lathe work the barrel has had 100mm removed a 14x1 thread cut and a end cap to suit. shaped and mounted the picatinny rail. rubbed a bit of cold blue on the exposed metal to stop the corrosion until i can get it down to taupo for a cera coat job. mounted the old bushnell on her to make her bush ready. the final job will see a custom made suppressor hanging off the end.

after a bit of lathe work the barrel has had 100mm removed a 14x1 thread cut and a end cap to suit. shaped and mounted the picatinny rail. rubbed a bit of cold blue on the exposed metal to stop the corrosion until i can get it down to taupo for a cera coat job. mounted the old bushnell on her to make her bush ready. the final job will see a custom made suppressor hanging off the end.

-

30-12-2014, 12:15 PM #8Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,335

Mucko, it is very important that barrel threading is done concentric with the bore, not he outside of the barrel, as they are frequently not concentric as they come from the factory. The correct method is to set the barrel up in a 4 jaw chuck and clock the bore true using a neat fitting bore mandrel. Also make sure (with shims etc) that the bore is running true at the back of the spindle bore. Failure to do this could result in the bullet striking the suppressor baffles.

-

22-05-2015, 12:27 PM #9Nothing is tough about having a 70 lb bow and looking like an uncoordinated praying mantis while trying to draw it back.

-

18-12-2017, 04:47 AM #10Member

- Join Date

- Dec 2017

- Location

- Scotland

- Posts

- 127

Here's my first fibreglass stock that I've made. It's cerakoted OD Green. Stock weighs 1077g. I'm working on a carbon fibre version that should weigh about 700g. LOP is longer than standard at about 15".

Rifle specs: Sako 75, 6x45, 20.5" 8 twist Pac Nor barrel, Tungsten Cerakote, Sauer 202 open sights, threaded M14x1 for Atec CMM-4 moderator/suppressor. Weight is about 4.5kg I think with Vortex Viper 4-16x44, modified Browning A-Bolt DNZ mount and moderator.

It shoots 105gr Amax's accurately at about 2500fps, or 62gr GSC copper bullets at 3350fps (perfect for deer).

Pics courtesy of the riflesmith who did the rebarreling, various thread tapping and cerakoting etc, PJS Precision, here in Scotland.

-

22-01-2018, 04:29 PM #11

That stock looks great. What type of mould did you use? Did you shape a plug yourself or use an existing stock as a pattern? Composites is my trade, so I have always toyed with the idea of carbon stocks but never got around to it.

-

24-01-2018, 07:04 AM #12Member

- Join Date

- Dec 2017

- Location

- Scotland

- Posts

- 127

Thanks mate. I used the original wooden stock as the plug and made a parting board out of 6mm ply. I extended the plug and filled gaps with plasticine. I've donr a few carbon fibre attempts but failed due to cheap rubbish vacuum bags. I've since got decent composites specific vacuum bagging material that stretches better and got a good mould last time. Then I poured in the inletting resin too fast and cracked it. Next time it'll work!

Send me your whatsapp or email deets by pm and I can send you pics. It wasn't too difficult but was time consuming!

-

02-06-2019, 04:30 PM #13

Quick little job on a cold wet afternoon.

Recently picked up a Weaver V3 1-3x20 on here. It has coin slot type turrets, and I never seem to have coins with me...

Measured the radius and width of the slot (0.5 inch and 0.070) and turned a alu disc. Then cut it down in the mill and epoxied it to the scope cap.

I'll give it a quick spray with matt black when the epoxy has cured.

Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

Viva la Howa ! R.I.P. Toby | Black rifles matter... | #illegitimate_ute

-

03-06-2019, 08:17 AM #14OPCz

- Join Date

- Jun 2012

- Location

- Nor West of Auckland on the true right of the Kaipara River

- Posts

- 34,645

What a clever wee Vegemite you are ebf. You should patent that idea.

It takes 43 muscle's to frown and 17 to smile, but only 3 for proper trigger pull.

What more do we need? If we are above ground and breathing the rest is up to us!

Rule 1: Treat every firearm as loaded

Rule 2: Always point firearms in a safe direction

Rule 3: Load a firearm only when ready to fire

Rule 4: Identify your target beyond all doubt

Rule 5: Check your firing zone

Rule 6: Store firearms and ammunition safely

Rule 7: Avoid alcohol and drugs when handling firearms

-

03-06-2019, 09:34 AM #15

Similar Threads

-

Show me your knives

By moonhunt in forum Gear and EquipmentReplies: 2348Last Post: Yesterday, 12:19 PM -

Gun Porn, show off your new toys

By Philipo in forum Firearms, Optics and AccessoriesReplies: 9174Last Post: 07-04-2025, 08:09 PM -

Show us your Varmint rifles

By crzyman in forum Varminting and Small Game HuntingReplies: 251Last Post: 02-07-2019, 11:42 AM -

Working vs. show

By Pointer in forum Trial, Pedigree and Bird DogsReplies: 32Last Post: 17-01-2012, 10:04 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

227Likes

227Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

. But am just a bloody possum plucker not an GS .

. But am just a bloody possum plucker not an GS .

Bookmarks