I just thought this might be a project that might help someone else out.

I re barreled one of my vintage rifles recently.

Had it dialed up in the lathe to cut the chamber and realised it's bore was a bit tight for my chamber reamer pilot !

Groove is correct for 303.

So I tried to find a live pilot 303 or 30-303 with no luck.

So i went on with some other restorations because these problems usually sort themselves out over time and asking around.

In the end I had to bite the bullet and do it myself.

So my solid pilot reamer went in the Elliot tool and cutter grinder.

Locked in a canter and dialed up accurately.

The grinding wheel face and side are dressed to get a sharp corner.

Quite a few light cuts and a couple of re dressing the grinding wheel flat again to keep the corner sharp.

And I ground it down very nicely.

Added a circlip groove with a dremel wheel while it's still turning on the Elliot.

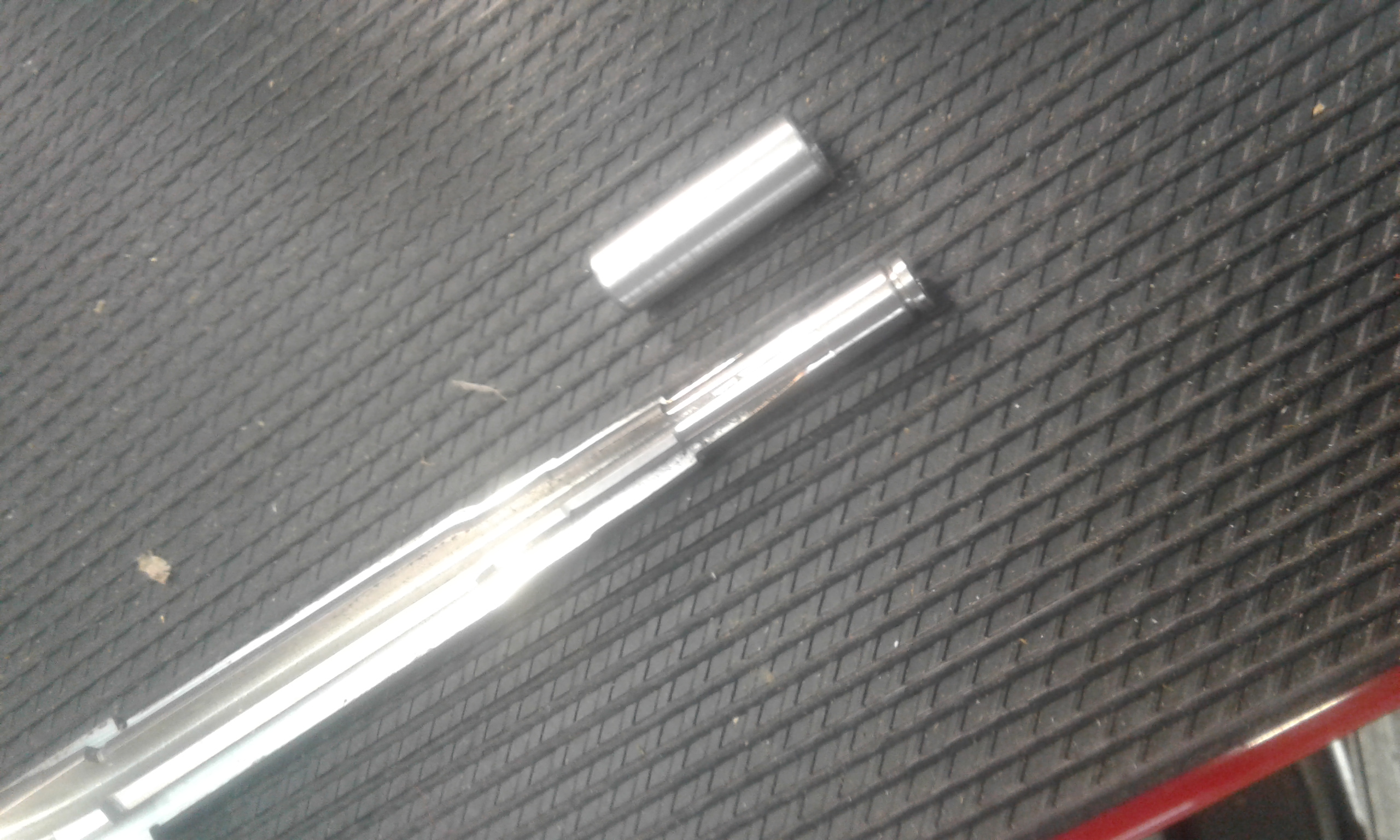

So now i grind a silver steel rod to bore diameter.

Then drill and ream it to a close fit to the pilot stub diameter.

Fit is perfect and this is now perfect for any bore I come across with custom pilots.

I just need a properly fitting circlip. Tried a tiny O-ring but it was a fraction over bore diameter. Tried a single coil of a spring but it has a slight twist and binds on the Bush

So I know not everyone has an Elliot. But there are plenty of handy ( non gun guys ) guys out there and tool makers who could do this for you if you have a funky bore.

Yes I could have taken 1 thou off the pilot and cut this chamber.

But then it would have been undersized for a standard or worn bore

Hope this helps someone

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 4 of 4

Hybrid View

-

13-08-2023, 08:42 AM #1Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,832

Turning a chamber reamer into a live pilot

The Church of

John Browning

of the Later-Day Shooter

-

13-08-2023, 10:13 AM #2Member

- Join Date

- Jun 2023

- Location

- waimakau

- Posts

- 4,384

Love reading about this type of thing. Can you get a small enough c clip?

-

13-08-2023, 12:59 PM #3Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,832

The Church of

John Browning

of the Later-Day Shooter

-

13-08-2023, 04:26 PM #4Member

- Join Date

- Oct 2022

- Location

- Pukekohe

- Posts

- 1,159

Clever fellow you are.... with a good head for thinking through the hurdle. Nice job.

Similar Threads

-

.22 TCM Chamber reamer.

By Wingman in forum ShootingReplies: 0Last Post: 15-10-2018, 11:27 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

16Likes

16Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks