Today there is the new pattern 5 inch filleting knife with blue/black acrylic over blue liners on the NitroV blade with honing steel. A set of scollops added for wet hand use.

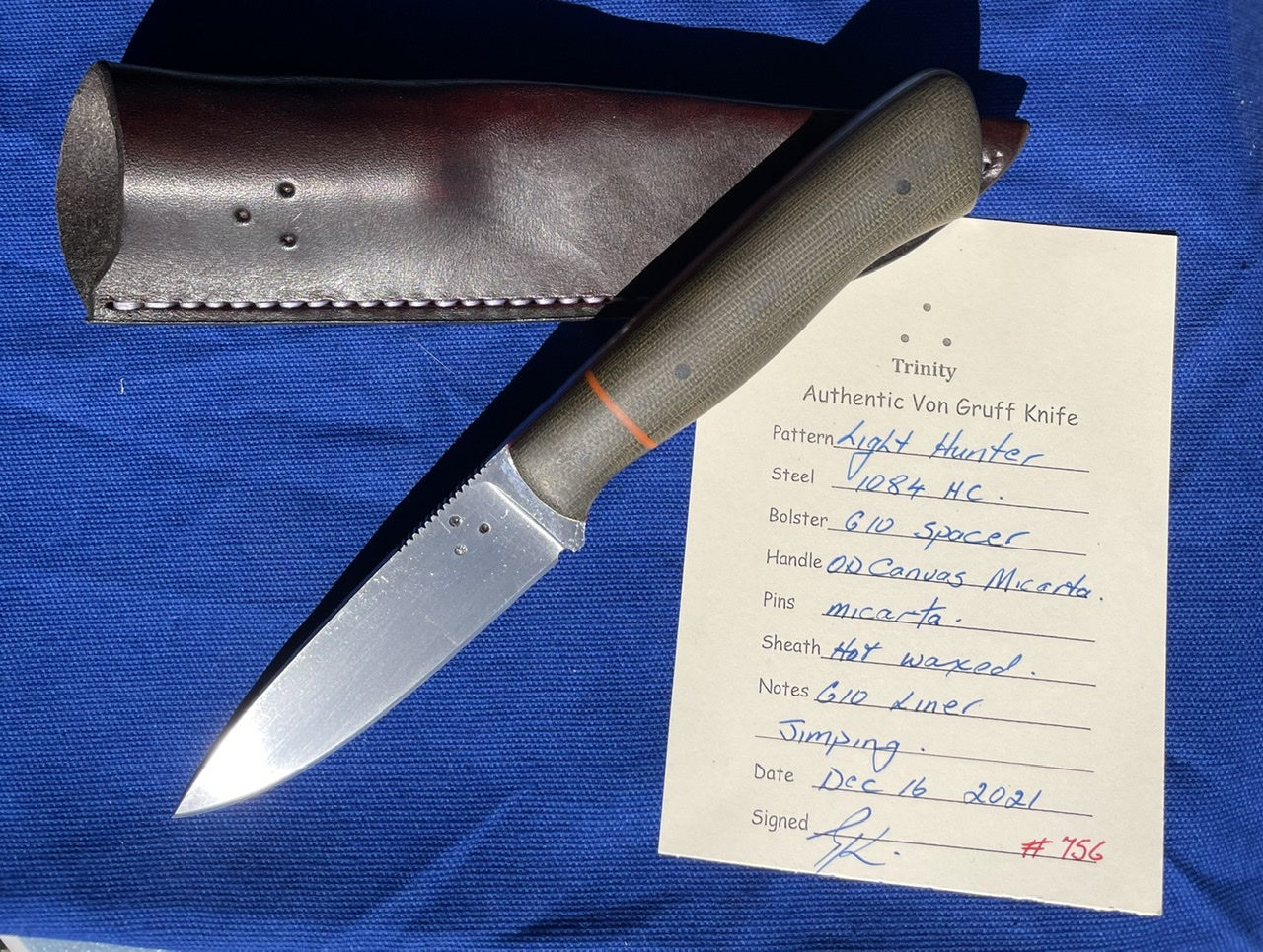

A Light Hunter with orange liners and bolster spacer under the OD canvas micarta handles on the 1084 blade. Customer asked for jimping so I bought a 15 LPI checkering file and that seemed to work well. A bit of shop clart to clean out of them to be cleaned out, but pleased with how they turned out.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 337

Thread: Various Knives

-

15-12-2021, 03:31 PM #31Member

- Join Date

- Aug 2021

- Location

- south otago

- Posts

- 340

-

-

15-12-2021, 03:38 PM #32Member

- Join Date

- Aug 2021

- Location

- south otago

- Posts

- 340

A few sheep shear knives all done. I take the grinds up as high as possible without interfering with the original markings

Macrocarpa and acacia

Eucalyptus and oak.

-

15-12-2021, 08:49 PM #33

No words neededForgotmaboltagain+1

-

15-12-2021, 09:39 PM #34Member

- Join Date

- May 2019

- Location

- Christchurch

- Posts

- 694

Now mate that is a thing of beauty

-

15-12-2021, 09:51 PM #35

-

16-12-2021, 12:18 PM #36Member

- Join Date

- Aug 2021

- Location

- south otago

- Posts

- 340

A slight lean to the blade to overcome the hollow and they cut straight and well. The depth of the handle allows for good controll in that regard. Most have gone for kitchen use but one is in Northern Territory as a field knife although I am not sure how practical that might be.

-

17-12-2021, 06:01 PM #37Member

- Join Date

- Aug 2021

- Location

- south otago

- Posts

- 340

-

18-12-2021, 10:44 AM #38Banned

- Join Date

- Mar 2015

- Location

- North Canterbury

- Posts

- 5,462

No, the ones I make are longer than a Bahco. I drill a cord hole through the end of the handle and the knife handle slips right down into the sheath leaving only 25mm handle protruding plus the cord. The bottom of the sheath comes well below the point of the knife and is open. I have found that the leather sheaths with stitching following the curve of the blade end up with the stitch cut and the knife potentially sticking into your leg when you crouch down. Then you end up stuffing the bottom of the sheath with greasy wool to stop the knife point sticking out

-

18-12-2021, 12:21 PM #39

I have lovely scar across shin from knife cutting way out of sheath and my pack some 25-30 years ago...ever since then I have put flattened piece of conduit pipe inside leather sheath so knife CANNOT cut its way out.....I should really secure conduit inside as occasionally it comes out on blade,but its a small inconvenience to have the security of knowing its safer.

-

18-12-2021, 12:54 PM #40

If you’re worried about the sheath just make your own from Kydex.

-

18-12-2021, 02:33 PM #41Member

- Join Date

- Aug 2021

- Location

- south otago

- Posts

- 340

If you make the sheath abnd hot wax (as I do) it to conform to the shape of the knife it sets almost like kydex so the risk of having the blade tip cut through the bottom of the sheath is mitigated as it would take a deliberate and very forcefull act to make it do so.

-

22-12-2021, 04:08 PM #42

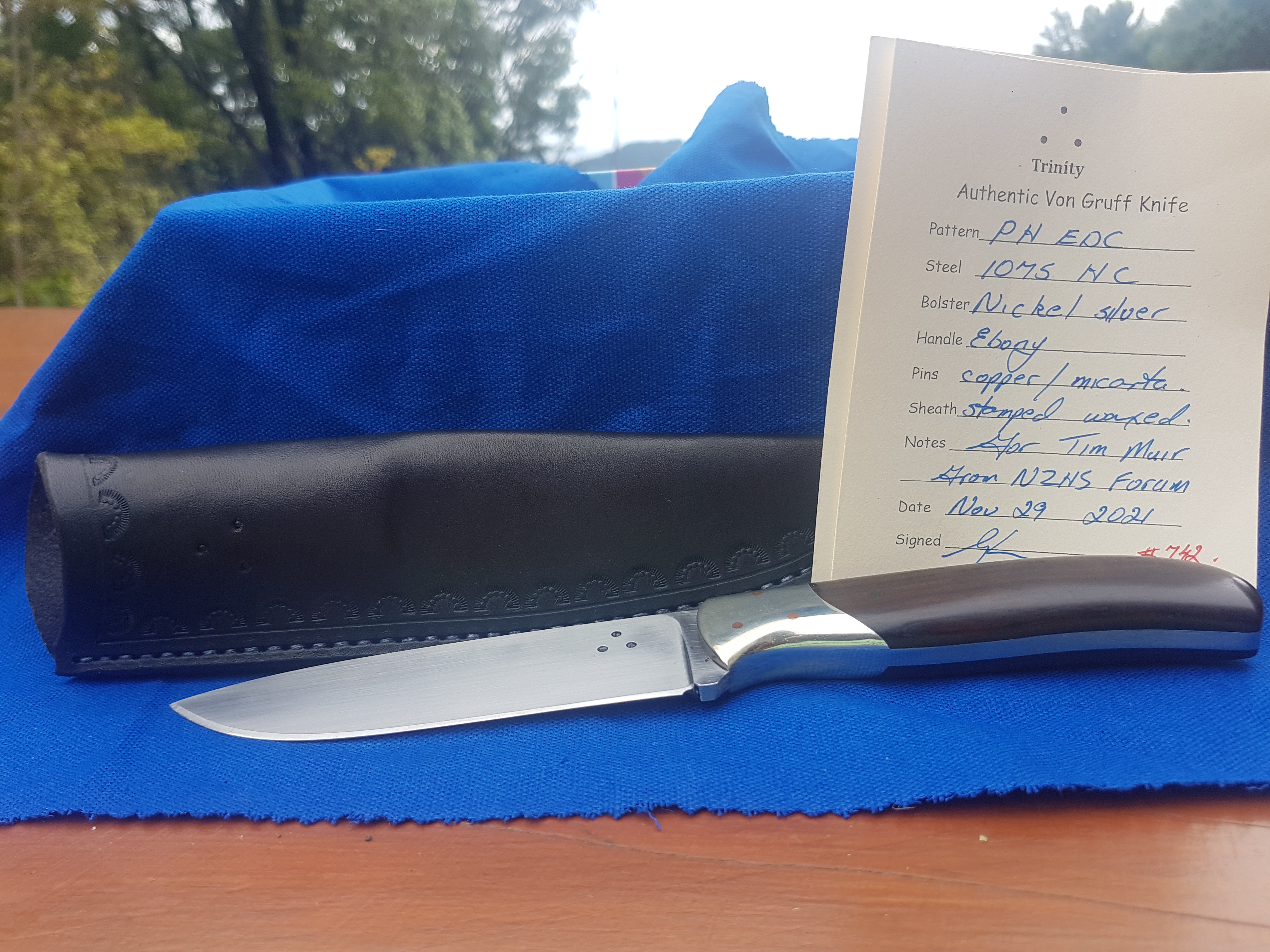

I’m the lucky recipient of the Light Hunter with gimping as above. Knife arrived yesterday and to say I was stoked is an understatement. The photos really don’t do the knife justice, really got to see them in the flesh to fully appreciate the quality of the design and craftsmanship that goes into them. The feel, weight and balance in the hand is superb, as is the leatherwork in the sheath. Many thanks Garry for quick turn around and the gimping. I’ve added a couple more pics that I hope here that I hope better show the knife.

-

24-12-2021, 03:38 PM #43Member

- Join Date

- Aug 2021

- Location

- south otago

- Posts

- 340

A friend on another forum asked --- do you make Viking knives and axes?

Loving a chalenge and making something new I found a design I really liked with a 10 1/4 inch blade and bought in a 30 layer bar of carbon damascus but decided to make one first from 1075 to prove the design before using the expensive damascus.

I ground it closer to finish than normal to hopefully show the hamon although grinding that thin can warp badly in the heat treat, but it is straight and ready for finish grind on blade and tang. A number of new things with this one so love the continuing chalenges this brings to the table.

After finish grinding, hand sanding and etching. I will try to make the hamon a bit more interesting next time with a bit more of a wave to it but happy with the way it turned out.

-

24-12-2021, 04:22 PM #44

@Von Gruff Knives On that topic,I am bit of a knife nut & for years l have used a Kizlyar DV-2 ,l got as a boat/camp knife while we were living/working in Arnhem Land & PNG & used it a lot while we hunted out of Air Boats in Oz & came to like it as a camp knife able to butcher whole carcasses if needed .

I have always liked the idea of having a similar knife & Hatchet/Axe set for my collection & using on our Jet Boat/rafting hunts.Is that something you would look at doing ,all just set up very tool like, as the DV2 gets used as basically a hatchet & butchering tool around camp used to cut poles for camp Fly's ,Batoning etc .Specs on the DV2 ,so something very similar able to take hard use, with just plain hard wearing handle/finish.

Total length: 365 mm (14.5")

Blade length: 235 mm (9.3")

Blade thickness: 5.2mm

Steel: U8"Fair Winds and Following Seas" - Capt Ron You Glorious Bastard.

"The nine most terrifying words in the English language are: I'm from the Government, and I'm here to help. " President Ronald Reagan

-

24-12-2021, 05:02 PM #45Member

- Join Date

- Aug 2021

- Location

- south otago

- Posts

- 340

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

874Likes

874Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks