I need it to keep my hyroponics operation going, thanks Mr Farmlands

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 78

-

25-03-2020, 09:59 PM #31Member

- Join Date

- Jul 2012

- Location

- Invervegas

- Posts

- 5,721

-

-

25-03-2020, 11:43 PM #32Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,975

So who on the forum has made the smokeless black powder?

-

26-03-2020, 07:39 AM #33Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,975

I'm a tree farmer

So have all sorts of wood available for the charcoal

Willow

Acacia

Hazel

Walnut

Euc

Leyland

Macro

Lusitanica

Lots of natives

So small lots of different charcoal could be tried to find what works best

-

26-03-2020, 06:47 PM #34

a coffee tin with hole in lid on the BBQ works too.....takes some time ,but its worth it in the end...the head off a sledgehammer and an old meatdish NOT MUMS GOOD ONE....and a couple of hours rolling the lumps down to fine grit works...so Im told.

-

26-03-2020, 08:03 PM #35

Sorry not a member of research gate.

Find a copy of “Life in the Gorge” by Les Marriott. He talks about making his own gunpowder in the depression and the resulting exploits.

-

26-03-2020, 08:07 PM #36

Flowering willow works best

Sent from my iPhone using Tapatalk

-

26-03-2020, 08:11 PM #37Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,975

I have heaps of willow

It's on my list for tomorrow to go cut and peel a heap

-

26-03-2020, 08:58 PM #38

Maybe you should speak to my mate. He’s a real enthusiast and has it pretty well sorted. Gets results equal to and better than commercially available stuff, and shoots quite a lot

Sent from my iPhone using Tapatalk

-

26-03-2020, 09:20 PM #39

Not smokeless, used green pussie Willow, peeled,paint tin with 2 small holes,cooked in a fire till gas stops burning, cover the holes and let it cool.

There's your charcoal. I ground it through a cast iron mincer then a gem tumbler with 50 cal round balls for about 4 hours.

Added some other ingredients, tumbled again at the full length of my longest extention cord,now you have "gunmeal"add 5% dexrin,dampen slightly and push it through fly screen mesh.let it dry on newspaper.

Quite fast and clean.Real guns start with the number 3 or bigger and make two holes, one in and one out

-

03-04-2020, 08:30 PM #40

I always thought the grains of the stuff you buy are very hard so at the damp stage it could be compressed into round pucks, then dried and then granulated, should give you nice hard grains with more oomp. I have found my case cleaner also is good for removing the spruce off my lead round balls, a ball mill!!!, nar. Have made a puck maker that fits in my reloading press, just for fun and giggles only you know.

-

04-04-2020, 02:32 PM #41

Good point!

I'm dramatically out of my depth in that I haven't done it myself, but have read about compressing BP to get the an accepted standardized density so that true BP (Not substitutes) is equal for both weight and volume at whatever that given density is, which I thinnnnnnnnnk came about because traditionally volumetric powder measures are far more practical, affordable, and robust in day to day life when people were using BP guns for feeding themselves or fighting. There may also be a benefit that hard BP grains don't disintegrate over time from shaking until they end up as FFFFg dust.

Also have a vague memory of black powder grain burn rates decreasing as density increased(??I may be wrong??), which could explain why people making their own are getting faster, fluffier powders at the same gravimetric weight than the denser commercial manufacturers.

Two neat pages relating to density vs weight

BP Conversion Sheet (revised December 2012) - would have been neat to see a 5 or 10 shot median velocity with same projectile/firearm with each load/powder

https://www.chuckhawks.com/blackpowder_volumetric.htm

I'm curious if one were to make smokeless(sulphurless) black powder, whether it would behave similarly at the standardized black powder compressed volumetric/gravimetric grain weight..... probably not, but would be neat to find out, and would certainly make measuring it with the normal BP volumetric scales easier.Last edited by canross; 04-04-2020 at 02:41 PM.

-

04-04-2020, 02:55 PM #42

There are no smokeless black powders the smoke cloud is solid potassium salts caused by the reaction of the nitrate with the sulphur and charcoal. Potassium carbonate, sulphate, and sulphide which gives the rotton eggs smell.

The gasses are colourless. Reducing or removing the sulphur might reduce the smoke in humid air as sulphur dioxide reacts with water to form sulphurous acid, the droplets of which are white.

This has really got me thinking about going back to making my own.

-

04-04-2020, 04:06 PM #43Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,975

-

05-04-2020, 09:14 AM #44

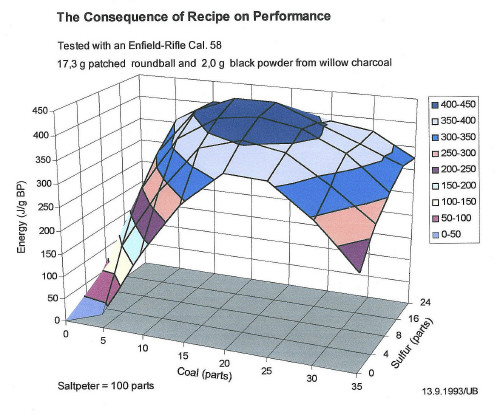

Ulrich Bretscher did that comparison in an Enfield muzzle loading rifle, home-made three-component gunpowder vs home-made two-component smokeless gunpowder. Found that the two-component was about 10% less powerful.

The page with the diagram above and the discussion around it.

Bretscher created an impressive three dimensional graph varying both sulfur and charcoal proportions.

Swiss artillery created a type of smokeless gunpowder created by the usual method but eliminating sulphur from the mixture. It overcame the problem in fortresses that you blinded yourself to what attackers were up to once you had fired the first cannon salvo, instead the two-component powder left a light haze. @Marty Henry's post above explains the difference.

To go on from your question canross, Bretscher mentioned that he wondered if the smokeless powder would behave differently in modern, large case small calibre bottlenecked cartridges rather than in an old Enfield muzzle loading rifle.An itch ... is ... a desire to scratch

-

10-04-2020, 03:22 PM #45

Thanks Cordite! I see what you're saying around the comparison of his two home made powders.

I think I usually write too much without being very clear - what I was trying to say (poorly) was I was curious about whether the sulphurless BP would behave the same was as sulphur based BP when compressed as part of the manufacturing process. You can make BP without pressing into pucks before graining it into Fg, FFG, FFFG etc, but you'll get a very light fluffy powder. Pressing into pucks then corning it down to the appropriate grain size gives you a "standard" powder. I have no idea what that standard is, but it seems like there is one. Again, I haven't done it, just read about it.

I didn't see Ulrich's write-up mention compressing his powder so that the mass (1 gr) matched whatever the accepted "standard" density of BP is, which apparently affects burn rate (from what I've read: as powder density increases from pressing, burn rate decreases). In that way I suspect that home made powders by their nature are faster burning than commercial powders because they are lower density, but at the cost of being less robust and bulkier.

Since we have powder measures that have volumetric graduations, and most countries historically used volumetric measurements for their powders, there must be some sort of accepted density for powders that most current commercial companies follow where they can say that X weight of BP equals Y Volume of BP. I know historically that exact density varied between countries, but within one area of standardization (military, country, region, alliance) they tried to keep that density fairly consistent so one batch of powder wouldn't be significantly stronger or weaker at a given charge volume than another (though it did happen as angry letters from supply agents to powder mills and officials demonstrate).

If the whole "density increase=burn rate decrease" thing is correct, then I'm curious if the two powders (sulphur and sulphurless) might behave the same or differently when compressed as part of manufacturing. Might be that the sulphurless stuff burns faster than its sulphur counterpart when compressed, or maybe it burns slower, or maybe compression doesn't affect it any differently than its identically treated sulphur-using counterpart. Maybe it's even harder to ignite when compressed, maybe it's easier. I'd assume that it would continue to be 10% less powerful in compressed form than its sulphur counterpart.... but maybe it isn't? If there wasn't a significant decrease in performance it would at bare minimum mean you could use your standard volumetric powder measure to measure loads with your muzzle loader and not have to offset your charge weight because it was a sulfurless powder.

Anyways, that's me rambling. It would make a fun experiment I guess is what I'm trying to say at the end of it all.

Similar Threads

-

Help with black powder rifle

By hollowpoint in forum Firearms, Optics and AccessoriesReplies: 29Last Post: 24-07-2013, 09:48 PM -

Help with black powder rifle

By hollowpoint in forum Questions, Comments, Suggestions, Testing.Replies: 4Last Post: 22-06-2013, 08:14 PM -

Black powder shotgun

By Toby in forum Reloading and BallisticsReplies: 10Last Post: 18-10-2012, 01:46 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

41Likes

41Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks