Any more progress?

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 54

-

04-10-2024, 10:32 AM #16Member

- Join Date

- Jun 2015

- Location

- Hamilton

- Posts

- 1,345

-

-

04-10-2024, 10:41 AM #17Member

- Join Date

- Jul 2012

- Location

- Timaru

- Posts

- 891

-

04-10-2024, 02:14 PM #18Member

- Join Date

- Jun 2015

- Location

- Hamilton

- Posts

- 1,345

Great work! Keep us updated, are you using the magazine or creating an internal box?

-

04-10-2024, 02:51 PM #19Member

- Join Date

- Jul 2012

- Location

- Timaru

- Posts

- 891

-

18-10-2024, 12:45 AM #20Member

- Join Date

- Dec 2017

- Location

- North Canterbury

- Posts

- 2,404

Any reason the length behind the trigger was extended? ARs and most chassis short trigger reach is one of the big ergonomic benefits (especially with the more vertical grips used on chassis) seems thats lost buy having the grip mount that far back. I know its probably a bit late for you but something to consider in future.

-

18-10-2024, 05:07 AM #21Member

- Join Date

- Jun 2015

- Location

- Hamilton

- Posts

- 1,345

Good point i never noticed that, the howa has a very straight trigger which closes that gap further by the looks

-

23-10-2024, 05:06 PM #22Member

- Join Date

- Jul 2012

- Location

- Timaru

- Posts

- 891

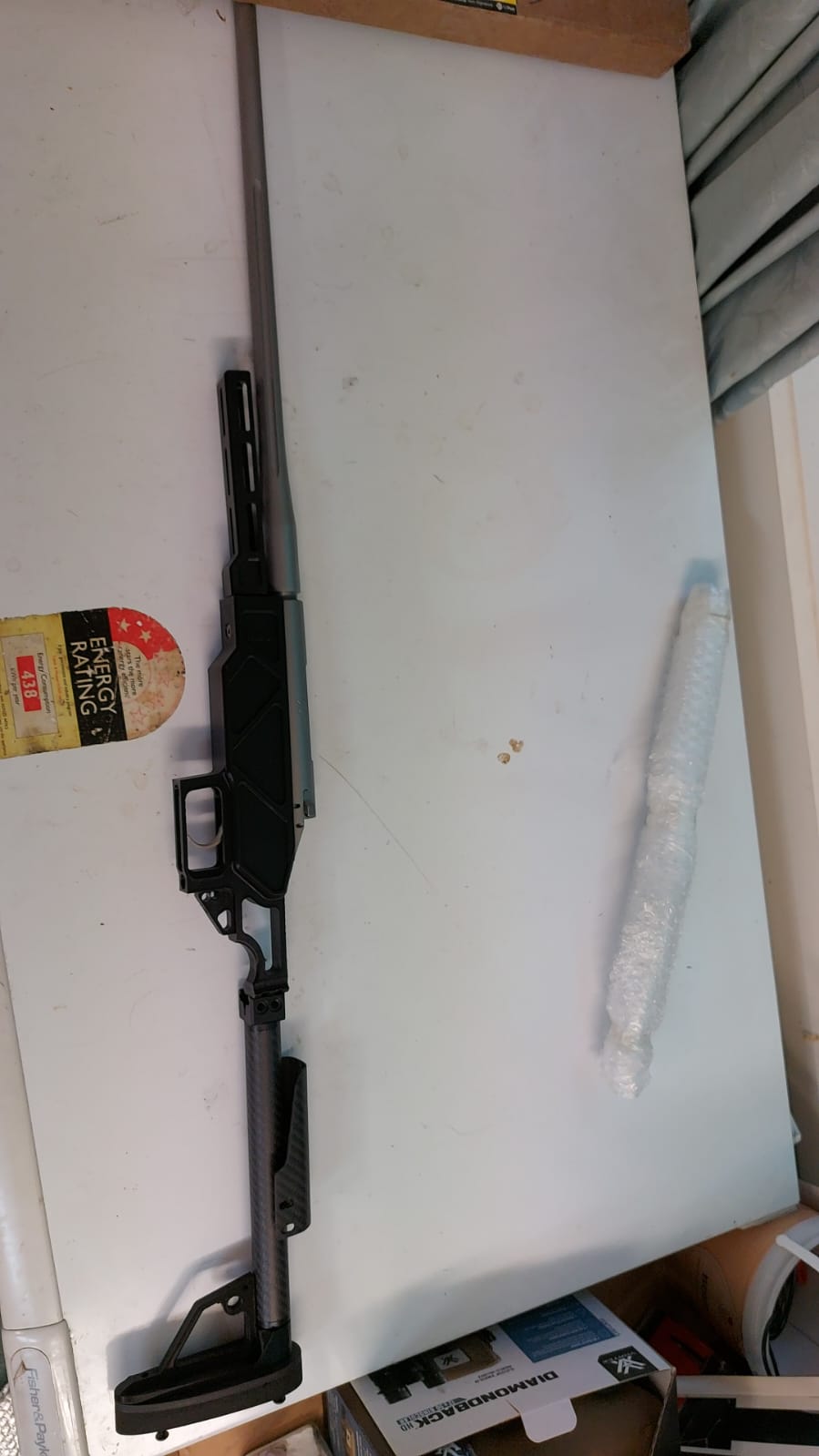

Done finally. A bit of a labour of love.

Has a QD pocket in the rear and threaded for a sling stud

Recoil pad for larger calibers unlike Elude

That barrel is 22" so a bit silly looking, will be chopped.

Uses the box mag

Have 3 or 4 available.CNC Machining

Hgprecision.net

-

24-10-2024, 08:33 AM #23Member

- Join Date

- Jul 2012

- Location

- Timaru

- Posts

- 891

Have been asked about what mag it takes,. Just the internal box steel mag.

Obviously in the pics it's sitting higher due to spring pressure.

Theres a slight chance a 3d printed plastic one could be made. Unsure it's longevity though. Nylon or carbon filled probably be ok

CNC Machining

CNC Machining

Hgprecision.net

-

24-10-2024, 09:10 AM #24Member

- Join Date

- Jun 2015

- Location

- Hamilton

- Posts

- 1,345

Could you machine the chassis to accept the factory mag? Otherwise id have to look at the 3d printing option which probably makes it unviable

-

24-10-2024, 08:00 PM #25Member

- Join Date

- Jul 2012

- Location

- Timaru

- Posts

- 891

-

24-10-2024, 08:07 PM #26

What does it weigh including the barrel and action?

O duh I missed it above

that would mean my 300WSM would be all up around 61/2lb incl scope, that may make it a handful to shoot wellTrust the dog.........................................ALWAYS Trust the dog!!

-

24-10-2024, 08:30 PM #27Member

- Join Date

- Jun 2015

- Location

- Hamilton

- Posts

- 1,345

74mmx31mm x 20mm

74mmx31mm x 20mm

-

24-10-2024, 08:38 PM #28Member

- Join Date

- Jul 2012

- Location

- Timaru

- Posts

- 891

Lengths the same, other measurements seem different, but it tapers so a little hard to tell. Wonder if a spare can be modified

CNC Machining

Hgprecision.net

-

24-10-2024, 09:04 PM #29Member

- Join Date

- Jun 2015

- Location

- Hamilton

- Posts

- 1,345

31ish at the tallest/back side. Id think spare kimber hunter mags to be quite thin on the ground

-

24-10-2024, 10:01 PM #30Member

- Join Date

- Dec 2011

- Location

- NI

- Posts

- 13,574

It would be very cool if these could take a Kimber Hunter and their detachable mag.

Out beyond ideas of wrongdoing, and right-doing, there is a field. I will meet you there.

- Rumi

Similar Threads

-

Expressions of interest: Rehoming a Lab x gsp

By superdiver in forum Hunting DogsReplies: 6Last Post: 29-12-2021, 06:23 AM -

Expressions of interest

By Shearer in forum Firearms, Optics and AccessoriesReplies: 19Last Post: 02-03-2018, 05:41 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks